This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

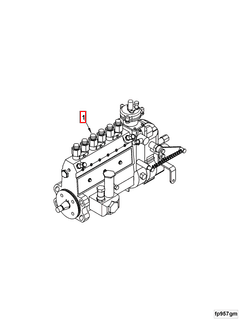

The Cummins 4063845 Fuel Injection Pump is a vital component in the operation of commercial trucks. It is designed to deliver fuel to the engine cylinders at precise times and pressures, ensuring optimal performance and efficiency. This part is integral to the overall functionality of the truck’s engine system, contributing to its reliability and effectiveness in various operational conditions.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine cylinders in diesel engines. It operates by pressurizing fuel and injecting it into the combustion chamber at the precise moment required for efficient combustion. The role of the fuel injection pump is crucial in ensuring that the engine runs smoothly and efficiently. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to manage fuel injection more precisely 1.

Purpose and Function of the Cummins 4063845 Fuel Injection Pump

The Cummins 4063845 Fuel Injection Pump plays a significant role in the operation of a truck by delivering fuel to the engine cylinders at exact times and pressures. This precise delivery ensures that the fuel combusts efficiently, which is vital for the engine’s performance. The pump works in conjunction with other engine components to maintain the correct fuel-air mixture, which is essential for optimal engine operation 2.

Key Features

The Cummins 4063845 Fuel Injection Pump is characterized by several key features. Its design incorporates high-quality materials that ensure durability and reliability under demanding conditions. The pump is constructed with precision-machined components to ensure accurate fuel delivery. Additionally, it may include unique technological aspects such as advanced metering systems that enhance fuel efficiency and engine performance.

Benefits of Using the Cummins 4063845 Fuel Injection Pump

The Cummins 4063845 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered at the optimal pressure and timing. This results in enhanced engine performance, as the engine operates more smoothly and with greater power. Additionally, the pump’s reliable design ensures consistent performance, reducing the likelihood of engine issues and downtime.

Installation and Integration

Proper installation and integration of the Cummins 4063845 Fuel Injection Pump into a truck’s engine system are important for ensuring its effective operation. It is important to follow the manufacturer’s specifications during installation to avoid potential issues. This includes ensuring that all connections are secure and that the pump is correctly aligned with other engine components. Adhering to these guidelines helps maintain the pump’s performance and longevity.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and efficiency of the Cummins 4063845 Fuel Injection Pump. This includes periodic inspections for wear and tear, cleaning or replacing filters, and checking for any signs of leaks. Common issues may include inconsistent fuel delivery or engine performance problems, which can often be traced back to the fuel injection pump. Troubleshooting tips may involve checking the pump’s connections, ensuring proper fuel pressure, and verifying the timing of fuel delivery.

Performance and Efficiency

The Cummins 4063845 Fuel Injection Pump contributes significantly to the overall performance and fuel efficiency of the truck. By ensuring precise fuel delivery, it helps the engine operate more efficiently, which can lead to better fuel economy. Additionally, proper fuel injection can reduce emissions, helping the truck comply with environmental regulations. The pump’s role in maintaining optimal engine performance is vital for the truck’s operational effectiveness.

Cummins Company Overview

Cummins Inc. is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and quality in engine manufacturing. The company offers a wide range of products, including engines, filtration systems, and power generation equipment. Cummins is known for its commitment to developing reliable and efficient solutions for its customers, ensuring that their products meet the high demands of commercial applications.

Role of Part 4063845 Fuel Injection Pump in Engine Systems

The part 4063845 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery. This pump works in conjunction with several key components to maintain optimal engine performance.

Interaction with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This ensures a consistent supply of fuel to the engine.

-

Fuel Filter: Before the fuel reaches the pump, it passes through the fuel filter. This component removes impurities and contaminants, protecting the pump from damage and ensuring clean fuel delivery.

-

Fuel Lines: The pump relies on fuel lines to transport fuel from the tank to the injectors. These lines must be in good condition to prevent leaks and maintain pressure integrity.

Coordination with Engine Components

-

Injectors: The pump delivers pressurized fuel to the injectors, which then atomize the fuel into the combustion chamber. This precise delivery is essential for efficient combustion and power generation.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the pump’s operation accordingly. This feedback loop ensures that the fuel injection is optimized for current driving conditions.

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber, where it is ignited by the spark plug or compression (in diesel engines). The pump’s role in delivering the right amount of fuel at the right pressure is vital for complete combustion and maximum efficiency.

Supporting Components

-

Return Lines: Excess fuel not used during injection is returned to the tank via return lines. This system helps regulate fuel temperature and pressure, contributing to the overall stability of the fuel injection process.

-

Pressure Regulator: This component works alongside the pump to maintain consistent fuel pressure, ensuring that the injectors receive a steady supply of fuel regardless of engine load or speed.

Conclusion

In summary, the Cummins 4063845 Fuel Injection Pump is a central element in the fuel delivery system, interacting with various components to ensure efficient and reliable engine operation. Its precise fuel delivery capabilities contribute significantly to the overall performance and efficiency of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.