This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

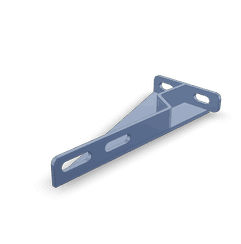

The Fuel Plumbing Bracket (Part #4062947) by Cummins is a component designed to support and organize the fuel lines within the fuel system of commercial trucks. Its role is significant as it ensures the proper routing and securement of fuel lines, contributing to the efficient and safe operation of the vehicle’s fuel system.

Basic Concepts of Fuel Plumbing Brackets

A fuel plumbing bracket is a structural component used in the fuel system to hold and organize fuel lines. It plays a role in maintaining the integrity and efficiency of the fuel delivery system by securing the lines in place, preventing them from moving or vibrating excessively, which could lead to wear, leaks, or other issues 1. The proper arrangement and support of fuel lines are vital for the consistent and reliable operation of a truck.

Purpose of the 4062947 Fuel Plumbing Bracket

This Cummins part is designed to secure and organize fuel lines within the truck’s fuel system. By holding the lines in place, it helps to prevent chafing, abrasion, and potential damage that could occur from movement or contact with other components. This bracket contributes to the overall operation of the truck by ensuring that the fuel lines remain in their intended positions, thereby supporting the efficient delivery of fuel to the engine.

Key Features

This part features a robust material construction, typically made from high-strength materials to withstand the demands of commercial truck environments. Its design includes precise mounting points and securement mechanisms to hold the fuel lines firmly in place. Additionally, the bracket may incorporate features such as vibration dampening elements to further protect the fuel lines from damage.

Benefits of Using the 4062947 Fuel Plumbing Bracket

Utilizing this part offers several advantages. It improves fuel line management by keeping the lines organized and securely in place, which can enhance the overall efficiency of the fuel system. Enhanced safety is another benefit, as secure fuel lines are less likely to leak or become damaged, reducing the risk of fuel-related incidents 2. Additionally, proper fuel line management can contribute to potential increases in fuel efficiency by ensuring a consistent and unobstructed fuel flow to the engine.

Installation and Compatibility

Proper installation of this part involves following manufacturer guidelines to ensure it is correctly mounted and the fuel lines are properly secured. Specific requirements may include ensuring the bracket is aligned with existing mounting points and that the fuel lines are routed according to the vehicle’s design specifications. Compatibility with various truck models and fuel systems should be verified to ensure optimal performance and integration within the vehicle’s fuel system.

Maintenance and Troubleshooting

To ensure the optimal performance of this part, regular inspection routines are recommended. This includes checking for signs of wear, corrosion, or damage to the bracket and the fuel lines it secures. Common issues that may arise include loose connections or damaged lines, which can be addressed by tightening or replacing affected components. Troubleshooting tips may involve verifying the bracket’s securement, ensuring fuel lines are not kinked or obstructed, and addressing any signs of fuel leaks promptly.

Safety Considerations

When working with the fuel system and installing or maintaining this Cummins part, it is important to observe safety guidelines and precautions. This includes working in a well-ventilated area, avoiding smoking or open flames near the fuel system, and wearing appropriate personal protective equipment. Additionally, ensuring the fuel system is depressurized before beginning work can help prevent accidents and ensure a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its product range, which includes components designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Cummins Engine Compatibility with Fuel Plumbing Bracket Part 4062947

This part is designed to be compatible with a range of Cummins engines, ensuring a secure fit and proper function within the engine’s fuel system. This bracket is integral for maintaining the alignment and integrity of fuel lines, which is crucial for the efficient operation of the engine.

G855 and G855 CM558 Engines

The G855 and G855 CM558 engines are part of Cummins’ lineup of heavy-duty engines. This part is engineered to fit these engines seamlessly, providing the necessary support for the fuel lines. This ensures that the fuel delivery system operates smoothly, reducing the risk of leaks and maintaining optimal engine performance.

GTA855 CM558 (CM2358) G101 Engine

The GTA855 CM558 (CM2358) G101 engine is another variant where this part is applicable. This bracket is designed to accommodate the specific layout and requirements of this engine model, ensuring that the fuel plumbing is correctly positioned and secured. This compatibility is essential for maintaining the engine’s efficiency and reliability.

N14 G Engine

The N14 G engine, known for its robust performance, also benefits from the use of this part. This bracket is tailored to fit the unique design of the N14 G engine, providing the necessary support for the fuel lines. Its precise fit ensures that the fuel system operates without issues, contributing to the engine’s overall performance and longevity.

Role of Part 4062947 Fuel Plumbing Bracket in Engine Systems

This part is an integral component in the assembly and operation of engine systems, specifically when interfacing with the module and fuel control components.

This bracket serves as a secure mounting point for the fuel lines, ensuring that they are properly aligned and supported as they route from the fuel source to the engine’s fuel control unit. Its design allows for efficient management of fuel lines, reducing the risk of chafing, abrasion, or disconnection under the dynamic conditions within an engine bay.

In conjunction with the module, the Fuel Plumbing Bracket helps maintain the structural integrity of the fuel delivery system. The module, which often includes sensors and control units, relies on a stable and unobstructed fuel supply. The bracket ensures that fuel lines are kept away from heat sources and moving parts, thus preserving the module’s functionality and the overall efficiency of the fuel system.

When integrated with the fuel control component, the bracket facilitates precise fuel metering by ensuring that the fuel lines are correctly positioned and tensioned. This is particularly important in high-performance engines where fuel delivery must be meticulously managed to optimize combustion and power output. The bracket’s role in supporting the fuel lines directly influences the fuel control’s ability to deliver the correct fuel-air mixture to the engine, enhancing performance and reliability.

Conclusion

The 4062947 Fuel Plumbing Bracket by Cummins is a critical component for the efficient and safe operation of commercial truck fuel systems. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of fuel line management and safety make it an essential part for maintaining the performance and reliability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.