Introduction

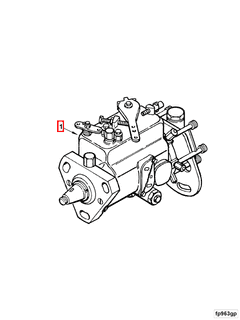

The Cummins 4020107 Fuel Injection Pump is a component designed for use in commercial trucks. It is responsible for delivering fuel to the engine cylinders at precise timing and pressure, which is vital for the efficient operation of diesel engines. This part is part of Cummins Inc.’s lineup of diesel engine components, known for their reliability and performance in demanding applications 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the fuel injection pump plays a role in the combustion process by injecting fuel at high pressure into the cylinders. This process relies on the principles of fuel injection, where fuel is atomized into fine particles to ensure efficient mixing with air for combustion. Fuel injection systems can be mechanical or electronic. Mechanical systems use physical components to control fuel delivery, while electronic systems utilize sensors and computer controls for more precise fuel management 2.

Purpose and Function of the Cummins 4020107 Fuel Injection Pump

The Cummins 4020107 Fuel Injection Pump is engineered to deliver fuel to the engine cylinders with exact timing and pressure. This precision ensures optimal combustion, which contributes to the engine’s power output and fuel efficiency. The pump operates by drawing fuel from the tank, pressurizing it, and then injecting it into the cylinders at the correct moment in the engine’s cycle 3.

Key Features

The Cummins 4020107 Fuel Injection Pump is characterized by its robust design and construction, which includes high-quality materials that enhance durability and performance. It incorporates advanced technological features that improve fuel delivery precision and reliability. These features contribute to the pump’s ability to withstand the rigors of commercial truck operation.

Benefits of Using the Cummins 4020107 Fuel Injection Pump

Utilizing the Cummins 4020107 Fuel Injection Pump offers several advantages, including improved fuel efficiency, enhanced engine performance, and increased reliability. These benefits are achieved through the pump’s precise fuel delivery, which ensures efficient combustion and reduces fuel consumption. The pump’s reliability contributes to consistent truck operation, minimizing downtime and maintenance costs.

Installation and Integration

Proper installation and integration of the Cummins 4020107 Fuel Injection Pump into a truck’s engine system are important for ensuring optimal performance. It is important to follow manufacturer specifications and procedures during installation to ensure compatibility and functionality within the engine system.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 4020107 Fuel Injection Pump. Regular inspections, cleaning, and replacement of worn components can prevent issues and maintain efficiency. Common problems may include fuel delivery inconsistencies or pump wear, which can often be addressed through troubleshooting steps outlined by the manufacturer.

Performance Enhancements

There are potential performance enhancements and upgrades available for the Cummins 4020107 Fuel Injection Pump. Aftermarket options may offer increased fuel delivery capacity or improved precision, which can impact truck performance. These enhancements should be carefully considered to ensure compatibility and effectiveness.

Safety Considerations

When working with the Cummins 4020107 Fuel Injection Pump, it is important to adhere to safety protocols and considerations. This includes proper handling of fuel, use of personal protective equipment, and following manufacturer guidelines to prevent accidents and ensure safe operation.

Environmental Impact

The Cummins 4020107 Fuel Injection Pump plays a role in reducing emissions by ensuring efficient fuel combustion. This contributes to more sustainable truck operations by minimizing the environmental impact of diesel engines. The pump’s precision in fuel delivery helps to reduce unburned fuel and harmful emissions.

Cummins Corporation

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to innovation and quality in diesel engine and component manufacturing. The company’s history and reputation are built on a foundation of producing reliable and high-performance products, including the Cummins 4020107 Fuel Injection Pump.

Compatibility with Cummins Engines

The Cummins 4020107 Fuel Injection Pump is compatible with several engine models, including the 6B5.9, 6BT5.9, QSK19, QSK60, and L10 engines. These engines are often used in heavy-duty and industrial applications, where reliable and efficient fuel delivery is critical. The compatibility of the 4020107 fuel injection pump with these engines ensures that they perform optimally, providing the necessary power and efficiency for their respective applications.

Role in Engine Systems

The Cummins 4020107 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, working in concert with other parts to ensure optimal performance. When the engine is started, the Base Fuel Pump draws fuel from the tank and delivers it to the 4020107 Fuel Injection Pump. This pump then pressurizes the fuel to the required levels for injection into the engine’s combustion chambers. The pressurized fuel is then distributed to individual injectors, which are responsible for spraying atomized fuel into the cylinders at precise moments in the engine cycle. This timing is essential for efficient combustion and power generation. The 4020107 Fuel Injection Pump also plays a role in regulating fuel flow based on engine demand. Sensors throughout the engine system provide data on variables such as engine speed, load, and temperature. This information is processed by the engine control unit (ECU), which then adjusts the operation of the 4020107 Fuel Injection Pump to meet the engine’s needs.

Conclusion

The Cummins 4020107 Fuel Injection Pump is a critical component in the operation of several engine models, ensuring efficient and accurate fuel delivery to the engine’s combustion chambers. Its compatibility with various Cummins engines, including the 6B5.9, 6BT5.9, QSK19, QSK60, and L10, ensures optimal performance and reliability. The pump’s role in the fuel delivery system is essential for maintaining consistent power output and fuel economy, making it a valuable component in heavy-duty and industrial applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.