The Cummins 4019575 Fuel Injection Pump is a component designed for use in heavy-duty trucks, playing a significant role in the operation of diesel engines. Within the context of diesel engine technology, this pump is integral to the fuel delivery system, ensuring that the engine operates efficiently and effectively 3.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are devices that deliver fuel into the combustion chambers of diesel engines. They operate by pressurizing fuel and injecting it at precise moments to optimize combustion. The importance of these pumps in diesel engines lies in their ability to control the timing and quantity of fuel delivery, which directly affects engine performance and emissions 1. Mechanical and electronic fuel injection systems differ primarily in their control mechanisms; mechanical systems rely on physical components and linkages, whereas electronic systems use sensors and electronic control units (ECUs) for more precise fuel delivery 2.

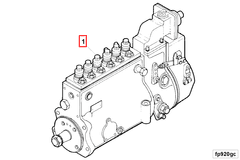

Purpose of the Cummins 4019575 Fuel Injection Pump

This Cummins part is designed to deliver precise amounts of fuel into the engine’s combustion chambers. Its role is to ensure that fuel is injected at the correct pressure and timing, which is crucial for efficient combustion, engine performance, and emissions control 3.

Key Features

This part features a robust design that incorporates high-quality materials to withstand the demanding conditions of heavy-duty truck operation. It includes technological advancements such as precise fuel metering and durable construction, which contribute to its reliability and performance 3.

Benefits

The advantages provided by this Cummins part include improved fuel efficiency, enhanced engine performance, and reduced emissions. By ensuring precise fuel delivery, the pump helps to optimize combustion, leading to better overall engine efficiency and lower emissions output 3.

Troubleshooting and Maintenance

Common issues with this part may include fuel delivery inconsistencies or pump wear. Troubleshooting steps may involve checking fuel lines for leaks, ensuring proper pump lubrication, and verifying the pump’s timing. Regular maintenance practices, such as cleaning and inspecting the pump, can help ensure optimal performance and longevity 3.

Integration with Engine Management Systems

This part interacts with modern engine management systems through electronic control units (ECUs) and sensor feedback loops. This integration allows for precise control of fuel delivery, adapting to various operating conditions to optimize engine performance and efficiency 3.

Historical Development

The evolution of fuel injection technology leading up to this part has seen significant milestones and innovations. Early mechanical systems have given way to more advanced electronic systems, enhancing control over fuel delivery and improving engine performance and emissions 2.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its extensive product portfolio and reputation for quality and innovation. The company’s history is marked by a commitment to developing reliable and efficient engine components, including fuel injection systems 3.

Environmental Impact

This part plays a role in meeting emissions regulations and contributing to sustainable transportation solutions. By ensuring precise fuel delivery and efficient combustion, the pump helps reduce harmful emissions, aligning with environmental goals for cleaner and more sustainable transportation 3.

Compatibility

This part is designed to fit seamlessly with various Cummins engine models, enhancing their efficiency and reliability.

Compatible Engines

-

6B5.9 Series: This part is specifically engineered to integrate with the 6B5.9 engine series. This compatibility ensures that the pump meets the unique demands of the 6B5.9 engines, providing consistent fuel delivery and maintaining engine performance 3.

-

Other Cummins Engines: While the primary focus is on the 6B5.9 series, this part may also be compatible with other Cummins engine models. Its design and specifications are crafted to align with Cummins’ broader engine lineup, ensuring a reliable fit and function across various applications 3.

Integration and Performance

When installed in the 6B5.9 engines, this part works in harmony with the engine’s architecture, delivering fuel at the precise moment required for combustion. This synchronization is crucial for maintaining engine efficiency, reducing emissions, and extending the engine’s operational lifespan 3.

The pump’s design incorporates advanced technology to ensure it meets the stringent requirements of modern diesel engines. This includes features such as high-pressure fuel delivery, precise timing control, and robust construction to withstand the rigors of continuous operation 3.

Installation Considerations

Proper installation of this part is essential to ensure it functions correctly. Technicians should follow Cummins’ recommended procedures for installation, including the use of appropriate tools and adherence to torque specifications. This ensures that the pump is securely mounted and aligned with the engine’s fuel system, preventing leaks and ensuring optimal performance 3.

Regular maintenance and inspection of the fuel injection pump are also critical. This includes checking for wear and tear, ensuring all connections are tight, and verifying that the pump operates within its specified parameters. Proper maintenance helps to avoid unexpected failures and prolongs the life of both the pump and the engine 3.

Role of Part 4019575 Fuel Injection Pump in Engine Systems

This part is an integral component in the fuel delivery system of an engine, working in conjunction with several other components to ensure efficient and precise fuel delivery 3.

When the Fuel Injection Pump receives fuel from the tank via the fuel lines, it pressurizes the fuel to the required levels. This pressurized fuel is then delivered to the Bosch Injection Pump, where it is metered and timed for injection into the combustion chamber 3.

The Bosch Injection Pump, a high-pressure pump, relies on the consistent and pressurized fuel supply from this part to function effectively. It uses a cam-driven mechanism to deliver fuel at the precise moment and in the exact quantity needed for optimal combustion 3.

This part also interacts with the engine’s Electronic Control Unit (ECU). The ECU monitors various engine parameters and sends signals to the Fuel Injection Pump to adjust the fuel delivery as needed, ensuring the engine operates within its optimal performance range 3.

Additionally, this part works in harmony with the fuel filter, which cleans the fuel before it reaches the pump. This ensures that the Fuel Injection Pump and the Bosch Injection Pump receive clean fuel, free from contaminants that could impair their operation 3.

Conclusion

In summary, this part plays a significant role in the fuel delivery system, ensuring that the engine receives the right amount of fuel at the right time, in collaboration with the Bosch Injection Pump, fuel lines, fuel filter, and ECU. Its robust design, precise fuel metering, and integration with modern engine management systems contribute to improved engine performance, efficiency, and reduced emissions 3.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.