This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

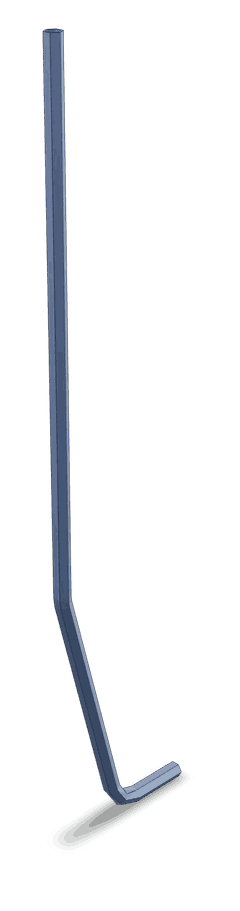

The Cummins Fuel Drain Tube, part number 4001228, is a component designed for use in the fuel systems of commercial trucks. Cummins, a prominent name in the automotive and heavy-duty truck industry, ensures that this part meets the rigorous demands of commercial vehicle operations. The Fuel Drain Tube facilitates the safe and efficient drainage of fuel, which is integral to the maintenance and operation of truck fuel systems.

Purpose and Function

This Cummins part is engineered to allow for the controlled drainage of fuel from the system. This function is vital for several reasons. It enables the removal of water and contaminants that may accumulate in the fuel, thus helping to maintain the integrity and efficiency of the fuel system. Additionally, it provides a means for periodic fuel system maintenance, which is important for ensuring consistent performance and longevity of the truck’s engine.

Key Features

The design and construction of the Fuel Drain Tube are tailored to meet the specific needs of commercial truck fuel systems. It is made from durable materials that can withstand the pressures and temperatures encountered in such environments. The tube features secure connection types that ensure a tight seal, preventing leaks and ensuring that the drainage process is both safe and effective. Its design may also include features that simplify installation and maintenance, enhancing its practicality in a commercial setting.

Benefits

Incorporating the Fuel Drain Tube into a truck’s fuel system offers several advantages. It contributes to improved fuel system efficiency by allowing for the regular removal of contaminants. This, in turn, can lead to better engine performance and reduced wear on fuel system components. Additionally, by facilitating the drainage of fuel, it helps to minimize the risk of contamination, which can be detrimental to engine operation. The tube also enhances safety by providing a controlled means for fuel management, reducing the likelihood of spills or accidents during maintenance procedures.

Installation and Compatibility

Proper installation of the Fuel Drain Tube is important for ensuring its effective operation. Installation procedures should follow manufacturer guidelines to ensure compatibility with the specific truck model and fuel system. Attention to detail during installation can prevent issues such as leaks or improper drainage, which could affect the performance of the fuel system.

Maintenance and Troubleshooting

Routine maintenance of the Fuel Drain Tube is important for its optimal functioning. This may include regular inspections for signs of wear or damage, ensuring connections remain secure, and performing drainage procedures as recommended by the manufacturer. Troubleshooting common issues, such as leaks or blockages, may involve checking for proper installation, ensuring connections are tight, and clearing any obstructions within the tube.

Safety Considerations

When working with the Fuel Drain Tube, it is important to observe safety protocols and precautions. This includes proper handling procedures to avoid spills or accidents, and adhering to manufacturer guidelines for installation, maintenance, and operation. Understanding the properties and hazards associated with fuel is also important for ensuring a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation within the commercial truck industry. The company’s product offerings are known for their reliability and performance, making Cummins a preferred choice for commercial vehicle operators. The development and quality assurance of parts like the Fuel Drain Tube reflect Cummins’ commitment to providing high-quality components that meet the demands of the industry 1.

Cummins Engine Compatibility with Fuel Drain Tube Part 4001228

The Cummins Fuel Drain Tube part number 4001228 is designed to facilitate the removal of accumulated water and sediment from the fuel system. This part is integral to maintaining the operational efficiency and longevity of the engine by ensuring that the fuel remains clean and free from contaminants.

QSK45 CM500 and QSK60 CM500 Engines

The Fuel Drain Tube part 4001228 is specifically engineered to fit seamlessly within the fuel systems of the QSK45 CM500 and QSK60 CM500 engines. These engines are part of the Cummins QSK series, which is renowned for its robust design and high performance in various industrial applications. The integration of the fuel drain tube in these engines ensures that the fuel system can effectively manage the separation of water and sediment, which is crucial for preventing engine damage and maintaining optimal performance.

The installation of the fuel drain tube in these engines is straightforward, designed to align with the engine’s fuel system architecture. This ensures that the tube can efficiently channel the separated water and sediment away from the fuel, thereby maintaining the purity of the fuel that reaches the engine’s combustion chambers. The precision engineering of the part guarantees a secure fit, minimizing the risk of leaks and ensuring that the engine operates smoothly and efficiently.

By incorporating the Cummins Fuel Drain Tube part 4001228 into the QSK45 CM500 and QSK60 CM500 engines, users can benefit from enhanced engine reliability and performance. This part is a testament to Cummins’ commitment to providing high-quality components that meet the demanding requirements of industrial engines.

Role of Part 4001228 Fuel Drain Tube in Engine Systems

The Fuel Drain Tube is an integral component within the fuel system of various engine setups. Its primary function is to facilitate the safe and efficient drainage of fuel from the system, ensuring that any excess or contaminated fuel is removed. This is particularly important in maintaining the integrity and performance of the fuel system.

In the context of fuel plumbing, the Fuel Drain Tube is positioned to connect with the fuel lines and tanks. It allows for the periodic draining of fuel, which is essential for maintenance routines and ensuring that the fuel delivered to the engine is clean and free from contaminants. This connection point is typically found near the lowest part of the fuel system to ensure that all sediment and water can be effectively removed.

When considering the broader plumbing system of an engine, the Fuel Drain Tube plays a supportive role by integrating with other components such as filters and sensors. It ensures that the fuel passing through the system is of high quality, which in turn supports the efficient operation of the engine. The tube is designed to work in conjunction with valves and switches that control the flow of fuel, allowing for manual or automated drainage as needed.

Overall, the Fuel Drain Tube is a key element in the fuel system, contributing to the reliability and performance of the engine by ensuring that the fuel remains in optimal condition.

Conclusion

The Cummins Fuel Drain Tube, part number 4001228, plays a significant role in the maintenance and operation of commercial truck fuel systems. By facilitating the safe and efficient drainage of fuel, it helps to maintain the integrity and performance of the fuel system. Its design and construction are tailored to meet the specific needs of commercial truck fuel systems, ensuring durability, secure connections, and ease of maintenance. Incorporating this part into a truck’s fuel system offers several benefits, including improved fuel system efficiency, better engine performance, and enhanced safety during maintenance procedures. Proper installation, routine maintenance, and adherence to safety considerations are important for ensuring the effective operation of the Fuel Drain Tube. Cummins’ commitment to providing high-quality components is evident in the design and functionality of this part, making it a valuable component for commercial vehicle operators.

-

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.