This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

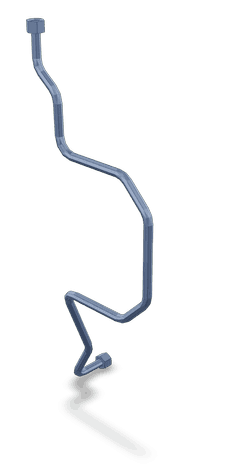

The Cummins 4001152 Fuel Drain Line is a component designed to facilitate the removal of excess fuel from the fuel system of commercial trucks. Its role is significant in maintaining the efficiency and safety of the truck’s operation. By ensuring that the fuel system operates within optimal parameters, this part contributes to the overall performance and reliability of the vehicle 1.

Basic Concepts of Fuel Drain Lines

A fuel drain line is an integral part of the fuel system, responsible for the removal of excess fuel and contaminants that may accumulate during operation. It operates by providing a pathway for fuel to be drained from the system, which helps in maintaining the cleanliness and efficiency of the fuel supply. This process is vital for ensuring that the engine receives clean fuel, which is important for efficient combustion and reduced emissions 4.

Purpose of the Cummins 4001152 Fuel Drain Line

The Cummins 4001152 Fuel Drain Line serves a specific function within the truck’s fuel system by allowing for the controlled drainage of excess fuel. This helps in maintaining the integrity of the fuel system by preventing overflow and reducing the risk of fuel contamination. By facilitating the removal of unwanted substances, it ensures that the fuel delivered to the engine is clean and of the correct quality, which is important for optimal engine performance 2.

Key Features

The Cummins 4001152 Fuel Drain Line is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the line may incorporate unique characteristics such as reinforced sections to withstand high pressure and flexible segments to accommodate movement within the truck’s fuel system 3.

Benefits of Using the Cummins 4001152 Fuel Drain Line

Utilizing the Cummins 4001152 Fuel Drain Line offers several advantages. It contributes to improved fuel system efficiency by ensuring that only clean fuel is circulated within the system. This reduces the risk of fuel contamination, which can lead to engine performance issues and increased maintenance costs. Furthermore, by maintaining the cleanliness of the fuel system, it supports enhanced overall truck performance, ensuring that the engine operates smoothly and efficiently 4.

Installation Considerations

Proper installation of the Cummins 4001152 Fuel Drain Line is important for ensuring optimal performance and longevity. It is recommended to follow manufacturer guidelines for installation, which may include specific torque settings for connections and the use of appropriate sealants to prevent leaks. Ensuring that the line is correctly routed and secured within the truck’s fuel system will help in maintaining its integrity and functionality over time 2.

Troubleshooting Common Issues

Common problems associated with fuel drain lines can include leaks, blockages, or improper drainage. To address these issues, it is important to conduct regular inspections of the line for signs of wear or damage. If a leak is detected, it may be necessary to replace fittings or sections of the line to restore its functionality. Blockages can often be cleared by flushing the line with a compatible cleaning solution, ensuring that fuel can flow freely through the system 3.

Maintenance Tips

Regular maintenance of the Cummins 4001152 Fuel Drain Line is important for ensuring it remains in optimal condition. This includes periodic inspections to check for signs of wear, corrosion, or leaks. Cleaning the line as part of routine fuel system maintenance can help in preventing the buildup of contaminants. Following a scheduled maintenance plan will help in identifying and addressing potential issues before they lead to more significant problems 4.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and aftermarket parts, Cummins has built a reputation for delivering reliable and high-performance solutions. The company’s focus on research and development ensures that its products meet the evolving needs of the industry, providing customers with the tools they need to operate efficiently and effectively 1.

Application in Cummins Engines

QSK45 CM500 and QSK60 CM500

The Fuel Drain Line part 4001152 is integral to the fuel management systems of the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and reliability in demanding applications. The fuel drain line ensures that any excess fuel is efficiently removed from the system, maintaining the integrity of the fuel supply and preventing potential issues that could arise from fuel accumulation 2.

Role of Part 4001152 Fuel Drain Line in Engine Systems

The Part 4001152 Fuel Drain Line is an essential component in various engine systems, facilitating the safe and efficient management of fuel. Its integration within the engine design ensures that excess or contaminated fuel is effectively removed from the system, maintaining optimal performance and safety 3.

Integration with Fuel Plumbing Systems

In the context of fuel plumbing, the Fuel Drain Line is strategically positioned to connect with the main fuel lines. This allows for the periodic draining of fuel, which is vital for maintaining the integrity of the fuel system. By providing a dedicated pathway for fuel drainage, it prevents the accumulation of contaminants that could otherwise lead to engine malfunctions 4.

Application in Fixture and Upfit Kits

The Fuel Drain Line is also a key component in various fixture and upfit kits, such as the Q45 S.O I Fixture Kit, Q60 S.O I Fixture Kit, Q60 SQI 2 Stage Upfit Kit, Q60 SQI Genset Upfit Kit, and Q60 SQI Ind Upfit Kit. In these applications, the line ensures that the fuel system remains clean and free from debris, which is particularly important in upfit kits where additional equipment is integrated into the engine system.

For instance, in the Q60 SQI 2 Stage Upfit Kit, the Fuel Drain Line allows for the safe removal of fuel during the two-stage upfitting process, ensuring that each stage is performed without the risk of fuel contamination affecting the engine’s performance. Similarly, in the Q60 SQI Genset Upfit Kit, it plays a role in maintaining the generator’s fuel system efficiency by allowing for regular drainage and inspection 2.

Ensuring System Reliability

By incorporating the Fuel Drain Line into these complex engine systems, engineers and mechanics can ensure that the fuel system remains reliable and efficient. Regular use of the drain line for maintenance purposes helps in identifying potential issues early, such as water ingress or fuel degradation, thereby preventing more significant problems down the line 3.

Conclusion

The Cummins 4001152 Fuel Drain Line is a vital component that enhances the functionality and safety of engine systems across various applications, from standard fuel plumbing to specialized upfit kits. Its role in maintaining the cleanliness and efficiency of the fuel system is crucial for ensuring optimal engine performance and reliability 4.

-

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ ↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ ↩ ↩ ↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ ↩ ↩ ↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.