The Fuel Supply Tube 4000585, manufactured by Cummins, is designed to facilitate the efficient delivery of fuel within heavy-duty trucks. This component is integral to the operation of the truck’s engine, ensuring that fuel is consistently and reliably supplied to the engine’s combustion chambers. Cummins, a well-established manufacturer in the heavy-duty truck industry, produces this component with a focus on durability, performance, and compatibility with their engine systems.

Basic Concepts of Fuel Supply Tubes

A Fuel Supply Tube serves as a conduit within the fuel system, responsible for transporting fuel from the fuel tank to the engine. Its function is vital for maintaining the engine’s performance, as it ensures that the fuel is delivered under the correct pressure and in the right quantity. The efficiency of the fuel supply tube directly influences the engine’s overall performance, including its power output and fuel efficiency 1.

Purpose of the 4000585 Fuel Supply Tube

The 4000585 Fuel Supply Tube plays a specific role in the fuel delivery system of a truck by ensuring a consistent flow of fuel to the engine. This component is designed to withstand the pressures and temperatures within the fuel system, providing a reliable pathway for fuel to reach the engine. Its design contributes to the stability of fuel delivery, which is crucial for the engine’s operation under various driving conditions 2.

Key Features

The 4000585 Fuel Supply Tube is characterized by several key features that enhance its performance and durability. These include its material composition, which is selected for resistance to fuel and the operational pressures within the system. The design elements of the tube, such as its diameter and length, are tailored to fit specific engine models, ensuring optimal fuel flow. Additionally, any unique characteristics, such as reinforced sections or specific coatings, are incorporated to improve its longevity and efficiency.

Benefits

Utilizing the 4000585 Fuel Supply Tube offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine without unnecessary loss or leakage. Enhanced engine performance is another advantage, as the consistent fuel supply supports stable combustion. Furthermore, the tube’s reliability in various operating conditions ensures that the engine operates smoothly, regardless of the external environment 3.

Installation Process

Installing the 4000585 Fuel Supply Tube requires careful attention to ensure proper fitting and function. The process involves several steps, including preparing the fuel system for the new component, aligning the tube with the existing fuel lines, and securing it in place. Tools and equipment necessary for installation may include wrenches, sealant, and possibly a fuel system cleaner. It’s important to follow manufacturer guidelines to ensure the tube is correctly installed, which includes checking for proper alignment and secure connections.

Troubleshooting Common Issues

Common issues with the 4000585 Fuel Supply Tube may include leaks or blockages, which can affect the engine’s performance. Troubleshooting these problems involves inspecting the tube and connections for signs of wear or damage, checking for proper alignment, and ensuring that all connections are secure. Addressing these issues promptly can prevent more significant problems with the fuel system and engine operation.

Maintenance Tips

Regular maintenance of the 4000585 Fuel Supply Tube is recommended to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear, corrosion, or damage, and cleaning the tube as necessary to remove any buildup that could affect fuel flow. Following the manufacturer’s guidelines for maintenance intervals and procedures can help maintain the efficiency and reliability of the fuel supply system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its wide range of engine and component products. With a history of innovation and quality, Cummins has established a reputation for producing reliable and high-performance parts. The company’s commitment to excellence is reflected in the design and manufacturing of components like the 4000585 Fuel Supply Tube, ensuring they meet the demanding requirements of heavy-duty applications.

Cummins Fuel Supply Tube 4000585 Compatibility

The Cummins Fuel Supply Tube part number 4000585 is a critical component in the fuel delivery system of various engine models. This part ensures the efficient and reliable transfer of fuel from the fuel tank to the engine’s fuel injection system. Below is a detailed description of how this part fits with specific Cummins engines.

K19 Engine Series

The Cummins K19 engine series is renowned for its robust performance and reliability, often used in heavy-duty applications such as construction and agricultural machinery. The Fuel Supply Tube 4000585 is integral to the K19 engine’s operation, ensuring that fuel is delivered consistently and accurately to the fuel injectors. This part is designed to withstand the high pressures and demanding conditions typical of these engines, contributing to their longevity and efficiency.

Grouping of Engines

The Cummins Fuel Supply Tube 4000585 is compatible with a range of engine models beyond the K19 series. It is engineered to fit seamlessly with other Cummins engines that share similar design and operational requirements. This compatibility ensures that the tube can be used across multiple platforms, providing a standardized solution for fuel delivery in various engine configurations.

Installation and Functionality

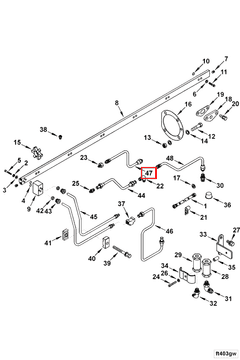

When installing the Fuel Supply Tube 4000585, it is crucial to ensure that it is properly aligned and securely fastened. This part typically connects to the fuel pump and extends to the fuel injectors, forming a continuous pathway for fuel flow. The design of the tube minimizes the risk of leaks and blockages, which are common issues in fuel delivery systems. Proper installation and maintenance of this component are essential for the optimal performance of the engine.

Application in Heavy-Duty Environments

In heavy-duty environments, the Cummins Fuel Supply Tube 4000585 is subjected to extreme conditions, including high temperatures, vibrations, and exposure to various contaminants. Its robust construction and precise engineering make it suitable for these demanding applications. The tube’s ability to maintain fuel flow integrity under such conditions is critical for the engine’s reliability and efficiency.

Compatibility with Other Cummins Engines

While the primary focus here is on the K19 engine series, the Fuel Supply Tube 4000585 is also compatible with other Cummins engines that share similar design parameters. This compatibility extends to various models within the Cummins engine lineup, ensuring that the part can be used across a broad range of applications. Technicians and mechanics should verify the specific compatibility of this part with their engine models to ensure proper fit and function.

Role of Part 4000585 Fuel Supply Tube in Engine Systems

The part 4000585 Fuel Supply Tube is an essential component in the fuel delivery system of an engine. It is responsible for transporting fuel from the fuel tank to the fuel injectors or carburetor, ensuring a consistent and reliable fuel supply for combustion.

Integration with Fuel Supply Components

-

Fuel Tank: The Fuel Supply Tube connects directly to the fuel tank, where it draws fuel through a pickup tube. This connection is designed to minimize fuel vaporization and ensure a steady flow of liquid fuel.

-

Fuel Pump: Positioned between the fuel tank and the engine, the Fuel Supply Tube works in conjunction with the fuel pump. The pump pressurizes the fuel, which is then delivered through the tube to the engine components.

-

Fuel Filter: Before reaching the engine, the fuel passes through a fuel filter. The Fuel Supply Tube facilitates this by providing a conduit that allows the filtered fuel to move from the filter to the fuel injectors or carburetor.

-

Fuel Injectors: In modern engines, the Fuel Supply Tube delivers pressurized fuel to the fuel injectors. These injectors spray atomized fuel into the combustion chamber, where it mixes with air and ignites.

-

Carburetor: In older engine systems, the Fuel Supply Tube feeds fuel into the carburetor. The carburetor then mixes the fuel with air before delivering it to the combustion chamber.

Interaction with Plumbing Components

-

Fuel Lines: The Fuel Supply Tube is often integrated with the vehicle’s fuel lines. These lines are responsible for routing fuel from the tank to various engine components. The tube ensures a secure and leak-free connection.

-

Fittings and Connectors: To ensure a tight seal and prevent fuel leaks, the Fuel Supply Tube is equipped with specialized fittings and connectors. These components are designed to withstand the pressure and temperature variations within the fuel system.

-

Return Line: In some systems, a return line is used to send excess fuel back to the tank. The Fuel Supply Tube may interact with this return line, ensuring that only the necessary amount of fuel is delivered to the engine.

By understanding the role and integration of the part 4000585 Fuel Supply Tube within these components, engineers and mechanics can better diagnose and resolve issues related to fuel delivery, ensuring optimal engine performance.

Conclusion

The 4000585 Fuel Supply Tube is a critical component in the fuel delivery system of heavy-duty trucks, ensuring efficient and reliable fuel supply to the engine. Its design and features contribute to improved fuel efficiency, enhanced engine performance, and reliability under various operating conditions. Proper installation, maintenance, and troubleshooting of this part are essential for optimal engine operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.