The Cummins 3964555 Fuel Injection Pump is a vital component in the operation of commercial trucks. This part is designed to deliver fuel to the engine at precise timing and pressure, ensuring optimal performance and efficiency. Its role in the fuel delivery system is significant, contributing to the overall functionality and reliability of the truck’s engine .

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at specific intervals, which are determined by the engine’s speed and load. In diesel engines, the fuel injection pump plays a role in ensuring that fuel is delivered at the right time and pressure to achieve efficient combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and linkages to control fuel delivery, while electronic systems use sensors and computer controls to manage the injection process .

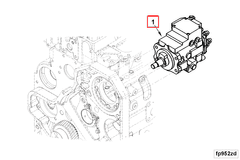

Purpose of the Cummins 3964555 Fuel Injection Pump

The Cummins 3964555 Fuel Injection Pump is responsible for delivering fuel to the engine at precise timing and pressure. This ensures that the fuel is atomized correctly and combusts efficiently, which is vital for the engine’s performance. The pump’s accurate fuel delivery helps maintain the engine’s power output, fuel efficiency, and emissions levels .

Key Features

The Cummins 3964555 Fuel Injection Pump is designed with several key features that enhance its performance and reliability. These include a robust construction using high-quality materials, precise engineering to ensure accurate fuel delivery, and technological advancements such as improved seals and bearings to reduce wear and leakage. The pump’s design also incorporates features that facilitate easy maintenance and integration into the engine system .

Benefits

The Cummins 3964555 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring precise fuel delivery, the pump helps the engine operate more efficiently, which can lead to lower fuel consumption and reduced emissions. Additionally, the pump’s robust construction and advanced features contribute to its durability and longevity, providing reliable performance over time .

Installation and Integration

Proper installation and integration of the Cummins 3964555 Fuel Injection Pump into a truck’s engine system are important for ensuring optimal performance. This process involves several steps, including preparing the engine compartment, aligning the pump with the fuel lines and engine components, and securing it in place. It is also important to check for any leaks or misalignments after installation to ensure the system operates correctly .

Troubleshooting Common Issues

Common problems associated with fuel injection pumps can include leaks, inconsistent fuel delivery, and pump failure. Diagnosing these issues often involves checking for visible signs of leakage, testing the pump’s pressure output, and inspecting electrical connections in electronic systems. Potential solutions may range from simple repairs, such as tightening connections or replacing seals, to more complex tasks like pump replacement or recalibration .

Maintenance Tips

Regular maintenance practices are important for ensuring the longevity and optimal performance of the Cummins 3964555 Fuel Injection Pump. This includes periodic inspections for leaks or wear, cleaning or replacing filters, and ensuring that all connections are secure. Additionally, following the manufacturer’s recommended service intervals for pump inspection and maintenance can help prevent issues and extend the pump’s lifespan .

Performance Enhancements

Possible upgrades or modifications to the Cummins 3964555 Fuel Injection Pump can include installing high-performance injectors, upgrading the pump’s internal components, or fine-tuning the fuel delivery system. These enhancements can improve engine performance and efficiency, providing better power output and fuel economy. It is important to ensure that any modifications are compatible with the engine and comply with relevant regulations .

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, the company has a long history of innovation and quality in the commercial truck industry. Cummins offers a wide range of products, including engines, powertrains, and aftermarket parts, and is known for its commitment to customer satisfaction and technological advancement .

Role of Part 3964555 Fuel Injection Pump in Engine Systems

The part 3964555 Fuel Injection Pump is a component in the fuel delivery system of an engine. It operates in conjunction with several other components to ensure efficient and precise fuel delivery, which is vital for optimal engine performance.

Interaction with the Fuel System

The Fuel Injection Pump works closely with the fuel injectors, delivering pressurized fuel at the correct timing and quantity. This precise delivery ensures that the fuel is atomized effectively when it enters the combustion chamber, leading to better fuel efficiency and reduced emissions .

Coordination with the Engine Control Unit (ECU)

The Fuel Injection Pump is often controlled by the Engine Control Unit (ECU). The ECU monitors various parameters such as engine load, RPM, and temperature to adjust the fuel delivery accordingly. This dynamic adjustment ensures that the engine operates within its optimal range under varying conditions .

Integration with the High-Pressure Fuel Pump (HPFP)

In systems where a High-Pressure Fuel Pump (HPFP) is present, the Fuel Injection Pump works in tandem to maintain the required fuel pressure. The HPFP boosts the fuel pressure initially, and the Fuel Injection Pump fine-tunes it for injection into the cylinders .

Relationship with the Common Rail System

In engines equipped with a Common Rail fuel system, the Fuel Injection Pump plays a role in maintaining the pressure within the rail. It ensures that fuel is always available at the required pressure for the injectors to operate efficiently .

Synergy with the Turbocharger

In turbocharged engines, the Fuel Injection Pump must adapt to the increased air intake provided by the turbocharger. It delivers more fuel to match the higher air-fuel ratio, ensuring that the engine produces maximum power without knocking or other performance issues .

Collaboration with the Exhaust Gas Recirculation (EGR) System

The Fuel Injection Pump also interacts with the Exhaust Gas Recirculation (EGR) system. By precisely controlling fuel delivery, it helps in reducing NOx emissions, which is a primary goal of the EGR system .

Impact on the Aftertreatment System

Efficient fuel delivery by the Fuel Injection Pump contributes to the overall performance of the aftertreatment system. By ensuring complete combustion, it minimizes the amount of unburnt fuel and other pollutants that reach the aftertreatment components, thereby enhancing their efficiency and longevity .

Conclusion

The Cummins 3964555 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. Its precise fuel delivery ensures optimal engine performance, efficiency, and reliability. Regular maintenance and proper installation are essential for maximizing the benefits of this part. Understanding its role and interactions within the engine system can help in troubleshooting issues and enhancing overall engine performance.

: Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

: Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

: Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991

: Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

: Engine D6.7 CM2670 D102B, Service Manual (5504515)

: Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

: Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

: Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

: Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991

: Engine D6.7 CM2670 D102B, Service Manual (5504515)

: Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

: Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

: Diesel Engines, A. J. Wharton, Butterworth-Heinemann Ltd, 1991

: Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

: Engine D6.7 CM2670 D102B, Service Manual (5504515)

: Automotive Heating Ventilation and Air Conditioning, Quansheng Zhan, Shengbo Eben, Li Kun Deng, Jones Bartlett Learning, 2018

: Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.