This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

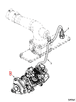

The Cummins 3957711 Fuel Injection Pump is a critical component in the operation of commercial trucks, ensuring precise fuel delivery to the engine cylinders. This pump is essential for efficient combustion and overall engine performance by delivering diesel fuel at the correct timing and pressure 2.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers by pressurizing it and injecting it at specific intervals based on the engine’s operational needs 1. In diesel engines, high-pressure fuel delivery is crucial for proper atomization and combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and linkages, while electronic systems utilize sensors and computer controls for optimized fuel injection 3.

Purpose of the Cummins 3957711 Fuel Injection Pump

This Cummins part is designed to deliver fuel to the engine cylinders with precision, ensuring correct timing and pressure for efficient combustion. It maintains engine performance by providing consistent fuel delivery, which helps achieve optimal power output and fuel efficiency 2.

Key Features

The Cummins 3957711 Fuel Injection Pump features a robust design with high-quality materials for durability and reliability. It includes advanced technological features such as precise fuel metering and high-pressure delivery capabilities, contributing to efficient performance. The pump is designed for easy integration into the engine system, facilitating straightforward installation and maintenance 1.

Benefits

This part offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. Precise fuel delivery leads to better combustion and more efficient fuel usage. The pump’s robust construction and advanced features contribute to the overall reliability and longevity of the engine 2.

Installation and Integration

Proper installation of the Cummins 3957711 Fuel Injection Pump is crucial for optimal performance. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines, ensuring secure connections and proper alignment with engine components. The fuel system should be clean and free of contaminants before installation 1.

Troubleshooting Common Issues

Common issues with this part may include inconsistent fuel delivery, leaks, or failure to start the engine. Troubleshooting steps involve checking the pump’s connections, inspecting for leaks, and ensuring the fuel system is free of contaminants. If the pump is not delivering fuel correctly, recalibration or replacement may be necessary. Regular maintenance and inspections can help identify and address potential issues 3.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3957711 Fuel Injection Pump. This includes periodic inspections for leaks, ensuring tight connections, and keeping the fuel system clean. Following the manufacturer’s recommended service intervals for replacing filters and performing other maintenance tasks is important. Using high-quality fuel and maintaining the engine well will contribute to the pump’s efficient operation 2.

Performance Enhancements

Performance enhancements for the Cummins 3957711 Fuel Injection Pump may include upgrades such as high-performance injectors or modifications to the fuel delivery system. These enhancements can improve the engine’s power output and efficiency. Ensuring compatibility with the pump and the engine system is crucial to avoid potential issues 1.

Environmental Impact

The Cummins 3957711 Fuel Injection Pump plays a role in reducing emissions and promoting cleaner operation by ensuring precise fuel delivery, leading to more efficient combustion. This helps minimize the release of harmful pollutants into the environment. The pump’s efficient operation contributes to better fuel economy, reducing the overall carbon footprint of the vehicle 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to sustainability, Cummins has made significant contributions to the automotive and diesel engine industries. The company’s mission is to power a more prosperous world by providing reliable and efficient power solutions that meet the needs of customers around the globe 2.

Compatibility

B4.5 Engine Family

The Cummins B4.5 engine series is renowned for its robust construction and high performance, often utilized in various industrial and commercial applications. The 3957711 fuel injection pump is specifically tailored to fit seamlessly within the B4.5 engine architecture, ensuring optimal efficiency, consistent power output, and fuel economy 1.

Integration and Performance

The integration of the 3957711 fuel injection pump with the B4.5 engine involves precise engineering to match the pump’s output with the engine’s fuel requirements. This ensures that the fuel is delivered at the correct pressure and timing, which is crucial for maintaining engine performance and longevity. The pump’s design allows for precise control over fuel delivery, which is essential for the smooth operation of the B4.5 engine 3.

Reliability and Maintenance

One of the key benefits of using the 3957711 fuel injection pump in the B4.5 engine is its reliability. Cummins is known for producing high-quality components that are built to last, and this pump is no exception. Regular maintenance and timely replacement of the pump can help prevent potential issues, ensuring that the engine continues to perform at its best 2.

Application Versatility

The 3957711 fuel injection pump is not limited to just the B4.5 engine family. Its design and engineering make it suitable for use in other Cummins engines as well, providing a versatile solution for various applications. This versatility is a testament to Cummins’ commitment to providing high-quality, reliable components that can be used across different engine models 1.

Role of Part 3957711 Fuel Injection Pump in Engine Systems

The Part 3957711 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, ensuring precise and efficient fuel delivery to the combustion chambers. Its role is to pressurize and meter the fuel, which is then injected into the engine’s cylinders at the optimal time for combustion 2.

Interaction with Other Components

- Fuel Tank: The fuel injection pump draws fuel from the tank, where it is stored under low pressure.

- Fuel Filter: Before reaching the pump, the fuel passes through a filter that removes impurities, ensuring clean fuel is delivered to the pump.

- Fuel Lines: These transport the fuel from the tank to the pump and subsequently to the injectors. The pump increases the pressure of the fuel as it moves through these lines.

- Fuel Injectors: The pressurized fuel is delivered to these components, where it is atomized into fine droplets and injected into the combustion chambers.

- Engine Control Unit (ECU): The ECU monitors various engine parameters and sends signals to the fuel injection pump to adjust the fuel delivery based on real-time data, optimizing performance and efficiency.

- Camshaft and Crankshaft Sensors: These sensors provide the ECU with information about the engine’s speed and position, allowing the fuel injection pump to time the fuel delivery precisely.

- Throttle Position Sensor: This sensor informs the ECU of the driver’s demand for power, influencing the fuel injection pump’s operation to match the engine load.

- Oxygen Sensors: Located in the exhaust system, these sensors measure the oxygen content in the exhaust gases. The ECU uses this data to fine-tune the fuel injection pump’s output, ensuring the air-fuel mixture is optimal for combustion efficiency and emissions control.

- Coolant Temperature Sensor: This sensor provides the ECU with engine temperature data, allowing the fuel injection pump to adjust fuel delivery for cold starts and varying operating temperatures, enhancing engine performance and longevity.

By working in concert with these components, the Part 3957711 Fuel Injection Pump ensures that the engine receives the right amount of fuel at the right time, contributing to smooth operation, improved fuel economy, and reduced emissions 3.

Conclusion

The Cummins 3957711 Fuel Injection Pump is a vital component in the fuel delivery system of commercial trucks, ensuring precise and efficient fuel delivery to the engine cylinders. Its robust design, advanced features, and compatibility with various engine models make it a reliable and versatile solution for enhancing engine performance and efficiency. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, contributing to improved fuel economy, reduced emissions, and overall engine reliability.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ ↩ ↩ ↩ ↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.