This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

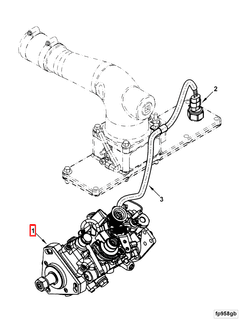

The Cummins 3957702 Fuel Injection Pump is a critical component for diesel engines, particularly in commercial trucks. This pump ensures efficient fuel delivery to the engine’s combustion chambers, highlighting the importance of reliable fuel systems in heavy-duty vehicles.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps pressurize diesel fuel and deliver it to the engine’s fuel injectors, which spray the fuel into the combustion chambers. The pump’s operation is synchronized with the engine’s rotation for optimal combustion timing. Types of fuel injection pumps include inline, rotary, and common rail systems, each offering specific advantages in efficiency, performance, and emissions control 1.

Purpose of the Cummins 3957702 Fuel Injection Pump

This Cummins part ensures fuel is delivered under high pressure to the injectors, enhancing engine performance through optimal fuel-air mixture for combustion. It also aids in emissions control by ensuring complete combustion, reducing unburned fuel and pollutants 2.

Key Features

The 3957702 is known for its robust design, high-quality materials, and technological advancements for enhanced performance. Its precision engineering allows for accurate fuel delivery and compatibility with various Cummins diesel engines, making it versatile for fleet management.

Benefits

Benefits of the 3957702 include improved fuel economy, enhanced engine performance, reduced emissions, and increased reliability. These advantages lower operating costs, improve vehicle uptime, and ensure compliance with emissions regulations, making it valuable for commercial truck applications 3.

Troubleshooting and Maintenance

Common issues with the 3957702 include leaks, inconsistent fuel delivery, and pump failure. Troubleshooting involves checking for leaks, ensuring proper fuel pressure, and inspecting for wear or damage. Maintenance practices include regular inspection, cleaning, and recalibration or replacement of worn components to prevent significant issues 4.

Cummins Overview

Cummins Inc. is a global leader in power solutions, including diesel and natural gas engines. The company is committed to advancing diesel engine technology through innovation and quality, as evidenced by products like the 3957702 Fuel Injection Pump.

Compatibility

The 3957702 is compatible with several Cummins engine models, including the B4.5 series and other engines with similar design and operational requirements. This compatibility ensures smooth engine operation and reliable fuel delivery.

Role in Engine Systems

The 3957702 plays a crucial role in the engine’s fuel delivery system, interacting with various components to ensure efficient engine operation. It works in concert with the fuel tank, fuel filter, fuel lines, fuel rail, fuel injectors, combustion chambers, Engine Control Unit (ECU), sensors, turbocharger, and Exhaust Gas Recirculation (EGR) system to maintain optimal performance and efficiency.

Conclusion

The Cummins 3957702 Fuel Injection Pump is essential for the efficient operation of diesel engines in commercial trucks. Its precise fuel delivery, compatibility with various engine models, and integration with the engine’s fuel system components ensure optimal engine performance, reduced emissions, and increased reliability. Regular maintenance and troubleshooting are key to maximizing the benefits of this part.

-

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Bruce Maclaurin. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Gunnar Stiesch. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

P. A. Lakshminarayanan and Nagaraj S. Nayak. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.