The Cummins 3957701 Fuel Injection Pump is a component designed for use in commercial truck engines. Manufactured by Cummins Inc., a leader in the diesel engine industry, this part is integral to the efficient operation of diesel engines in heavy-duty trucks. Its role is to deliver fuel to the engine at precise timing and pressure, ensuring optimal performance and efficiency.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. In diesel engines, it operates by pressurizing fuel and injecting it into the cylinders at the exact moment required for combustion. This process is essential for the engine’s efficiency, power output, and emissions control. The pump’s operation involves a series of mechanical and hydraulic processes that ensure fuel is delivered under high pressure and at the correct timing 1.

Purpose of the Cummins 3957701 Fuel Injection Pump

The Cummins 3957701 Fuel Injection Pump plays a role in the operation of a truck by delivering fuel to the engine at precise timing and pressure. This ensures that the fuel is atomized correctly upon injection, leading to efficient combustion. The pump’s accurate timing and pressure regulation are vital for maintaining engine performance, fuel efficiency, and emissions standards 2.

Key Features

The Cummins 3957701 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features such as precise fuel metering and electronic control capabilities. These features contribute to its reliability, durability, and efficiency in demanding commercial truck applications.

Benefits

The Cummins 3957701 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and reliability. By ensuring precise fuel delivery, it helps in optimizing the engine’s combustion process, leading to better fuel economy and power output. Its robust construction and advanced features also contribute to its longevity and reliability in heavy-duty truck applications.

Installation and Integration

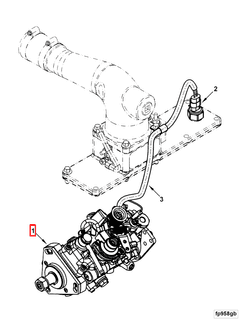

Installing the Cummins 3957701 Fuel Injection Pump into a truck engine requires adherence to specific procedures to ensure proper integration. This includes aligning the pump with the engine’s fuel system, securing it in place, and connecting it to the necessary electrical and mechanical components. Careful attention to these steps is important to ensure the pump operates correctly within the engine system.

Troubleshooting and Maintenance

Common issues with the Cummins 3957701 Fuel Injection Pump may include fuel delivery inconsistencies or mechanical wear. Diagnostic procedures involve checking for proper fuel pressure, timing, and leaks. Regular maintenance practices, such as cleaning and inspecting the pump, are important for ensuring optimal performance and longevity. Following the manufacturer’s guidelines for maintenance can help prevent issues and extend the pump’s service life.

Performance and Efficiency

The Cummins 3957701 Fuel Injection Pump contributes to the overall performance and efficiency of truck engines by ensuring precise fuel delivery. This leads to improved fuel economy and power output. Its role in the combustion process is vital for maintaining the engine’s efficiency and meeting emissions standards.

Safety Considerations

Operating and maintaining the Cummins 3957701 Fuel Injection Pump involves certain safety considerations. These include handling procedures to avoid fuel spills and ensuring the pump is securely installed to prevent leaks. Awareness of potential hazards, such as high-pressure fuel lines, is important during maintenance and repair activities.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and commercial vehicle industry. The company is known for its innovation, quality, and commitment to customer satisfaction, making it a preferred choice for heavy-duty truck engines and components.

Cummins Fuel Injection Pump 3957701 Compatibility

The Cummins Fuel Injection Pump part number 3957701 is a critical component in the operation of various diesel engines, ensuring precise fuel delivery for optimal performance and efficiency. This part is specifically designed to fit seamlessly within the engine architecture of several Cummins engines, providing a reliable and efficient fuel injection system.

B4.5 Engine Group

The Cummins B4.5 engine is a robust and dependable power unit commonly used in various industrial and commercial applications. The Fuel Injection Pump 3957701 is engineered to integrate flawlessly with the B4.5 engine, ensuring that the fuel delivery system operates smoothly and efficiently. This compatibility is crucial for maintaining the engine’s performance and longevity, as the fuel injection pump plays a pivotal role in the combustion process.

The B4.5 engine, known for its durability and reliability, benefits significantly from the precise fuel metering capabilities of the 3957701 pump. This ensures that the engine operates at peak efficiency, providing consistent power output and reducing the likelihood of mechanical failures.

By ensuring that the Fuel Injection Pump 3957701 is correctly matched with the B4.5 engine, users can expect enhanced performance, improved fuel economy, and a reduction in maintenance needs. This compatibility is a testament to Cummins’ commitment to providing high-quality, reliable components that meet the demands of modern diesel engines.

Role of Part 3957701 Fuel Injection Pump in Engine Systems

The 3957701 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines. It works in concert with several key components to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

-

Fuel Tank: The journey of fuel begins in the fuel tank, where it is stored until needed. The fuel injection pump draws diesel from the tank through the fuel lines.

-

Fuel Filter: Before reaching the injection pump, the fuel passes through the fuel filter. This component removes impurities and ensures that only clean fuel enters the pump, which is essential for the pump’s longevity and performance.

-

Fuel Lines: These carry the filtered fuel from the tank to the injection pump. The integrity of these lines is vital to maintain consistent fuel pressure and flow.

Fuel Injection Process

-

Fuel Injection Pump (3957701): This pump pressurizes the fuel to a high level necessary for injection into the engine’s combustion chambers. It meters the fuel precisely, ensuring the correct amount is delivered at the right time.

-

Injectors: The pressurized fuel is then delivered to the injectors. These components spray the fuel into the combustion chambers in a fine mist, optimizing air-fuel mixture for combustion.

Engine Components

-

Combustion Chambers: The atomized fuel mixes with air in these chambers. The high-pressure injection ensures thorough mixing, which is essential for complete combustion.

-

Pistons and Cylinders: The combustion process drives the pistons downward, converting chemical energy into mechanical energy. The fuel injection pump’s role in providing precise fuel delivery directly impacts the efficiency and power output of the engine.

-

Exhaust System: The byproducts of combustion are expelled through the exhaust system. Efficient fuel injection leads to cleaner and more complete combustion, reducing emissions and improving overall engine performance.

Supporting Systems

-

Engine Control Unit (ECU): Modern engines often use an ECU to monitor and adjust the fuel injection timing and quantity. The fuel injection pump must be compatible with such systems to ensure seamless integration and operation.

-

Sensors: Various sensors, such as the fuel pressure sensor and oxygen sensor, provide feedback to the ECU. This data helps in fine-tuning the injection process for optimal performance and efficiency.

Conclusion

In summary, the 3957701 Fuel Injection Pump is a pivotal component that ensures the precise delivery of fuel to the engine, interacting with a network of other components to maintain efficient and effective engine operation. Its robust design, advanced features, and compatibility with Cummins engines make it a reliable choice for heavy-duty truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.