This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

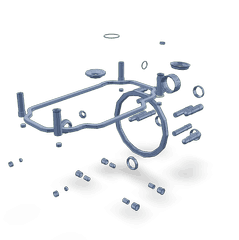

The Cummins 3957699 Fuel Injection Pump is a critical component for commercial trucks, ensuring efficient fuel delivery to the engine. This part is essential for the reliable operation of diesel engines in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this process involves drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at precise moments in the engine cycle 1. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms, while electronic systems employ sensors and computer controls for greater precision and efficiency 2.

Purpose of the Cummins 3957699 Fuel Injection Pump

The Cummins 3957699 is designed to deliver fuel at precise timing and pressure, ensuring optimal combustion. This consistent fuel delivery is vital for achieving the desired power output and fuel economy in diesel engines.

Key Features

This Cummins part features a robust design with high-quality materials for durability and reliability. It includes precision-engineered components to enhance performance and is built to withstand the demanding conditions of commercial truck operations 3.

Benefits of Using the Cummins 3957699 Fuel Injection Pump

Using this part offers several advantages, including improved fuel efficiency through optimal pressure and timing, resulting in more complete combustion and enhanced engine performance. Its reliable design also helps reduce downtime and maintenance costs.

Installation and Integration

Proper installation of the Cummins 3957699 is crucial for effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines, ensuring secure connections and proper alignment with engine components.

Troubleshooting and Maintenance

Common issues with fuel injection pumps include leaks, inconsistent fuel delivery, and pump failure. Regular maintenance, such as inspecting for leaks, ensuring proper lubrication, and following service intervals, can help prevent these issues. Troubleshooting may involve checking electrical connections, inspecting fuel lines, and ensuring correct voltage.

Performance and Efficiency

The Cummins 3957699 plays a significant role in the overall performance and efficiency of the truck. By delivering fuel at precise timing and pressure, it contributes to better fuel economy and increased power output, enhancing driving performance and reducing operating costs.

Technological Advancements

This part incorporates precision engineering and electronic controls to ensure accurate fuel delivery and enhance performance. These advancements contribute to the pump’s reliability and efficiency, making it a superior choice for commercial truck applications.

Environmental Impact

The Cummins 3957699 helps reduce emissions by ensuring efficient fuel combustion, contributing to lower levels of pollutants and promoting environmental sustainability in commercial trucking. Enhanced fuel efficiency also reduces the vehicle’s overall carbon footprint.

Cummins Corporation

Cummins Inc. is a global leader in designing, manufacturing, and distributing engines, filtration, and power generation products. With a history of innovation and a commitment to sustainability, Cummins has established itself as a trusted name in the commercial trucking sector.

Role of Part 3957699 Fuel Injection Pump in Engine Systems

The fuel injection pump, specifically part 3957699, is integral to the operation of diesel engine systems. It works in conjunction with several key components to ensure efficient fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank: The pump draws diesel from the fuel tank.

- Fuel Filter: The diesel passes through the fuel filter to remove impurities.

- Fuel Lines: The pump is connected to the fuel lines, which transport pressurized fuel to the injectors.

Coordination with Engine Components

- Injectors: Pressurized fuel is delivered to the injectors for atomized fuel spray into the combustion chambers.

- Camshaft: The pump is often driven by the engine’s camshaft, synchronizing fuel injection with piston movements.

- Crankshaft: The crankshaft influences overall engine timing, dictating when fuel injection occurs.

Supporting Systems

- Governor: Regulates the amount of fuel delivered by the pump.

- Sensors: Provide feedback to the engine control unit (ECU) for optimal performance and emissions control.

Impact on Engine Performance

The fuel injection pump’s role in delivering the right amount of fuel at the correct pressure and timing is crucial for:

- Combustion Efficiency: Ensuring complete and efficient burning of fuel.

- Power Output: Directly influencing the engine’s power and torque.

- Emissions: Contributing to lower emissions through precise fuel delivery.

Conclusion

The Cummins 3957699 Fuel Injection Pump is a vital component for the efficient and reliable operation of diesel engines in commercial trucks. Its precise fuel delivery, robust design, and technological advancements contribute to improved performance, efficiency, and environmental sustainability.

-

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive (5th ed.). Springer Vieweg.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.