Introduction

The Cummins 3946135 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with diesel engines. This part ensures that the engine receives the precise amount of fuel needed for optimal performance. Within the context of diesel engine technology, the fuel injection pump significantly enhances engine efficiency, power output, and emissions control 3.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is designed to deliver pressurized fuel to the engine’s combustion chambers at the precise moment required for efficient combustion. This process is fundamental to the operation of diesel engines, where fuel is ignited by the heat generated from compressing air within the cylinder, rather than by a spark plug as in gasoline engines. Fuel injection pumps can be mechanical or electronic. Mechanical pumps use cam-driven plungers to meter and deliver fuel, while electronic systems utilize sensors and a control unit to manage fuel delivery more precisely. Both systems aim to optimize fuel atomization, combustion efficiency, and emissions 4.

Purpose of the 3946135 Fuel Injection Pump

The Cummins 3946135 Fuel Injection Pump is specifically engineered to enhance the operation of diesel engines in commercial trucks. It ensures that fuel is delivered at the correct pressure and timing, which contributes to engine performance, fuel efficiency, and emissions control. By precisely metering the fuel injected into the combustion chamber, this part helps maintain consistent engine power and reduces the likelihood of incomplete combustion, which can lead to increased emissions and decreased fuel efficiency 1.

Key Features

The Cummins 3946135 Fuel Injection Pump boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that withstand the rigors of diesel engine operation. The pump features precise engineering to ensure accurate fuel delivery, and it includes technological advancements that improve its durability and efficiency. These features contribute to the pump’s ability to deliver consistent performance under varying operating conditions 2.

Benefits

The advantages offered by the Cummins 3946135 Fuel Injection Pump include improved fuel economy, enhanced engine power, reduced emissions, and increased durability. These benefits directly impact the overall operation and maintenance costs of commercial trucks. By ensuring efficient fuel delivery, the pump helps trucks achieve better mileage, which can lead to significant cost savings over time. Additionally, the pump’s role in emissions control helps trucks meet regulatory standards, avoiding potential fines and ensuring compliance with environmental regulations 3.

Installation and Integration

Proper installation of the Cummins 3946135 Fuel Injection Pump is crucial for its effective operation. Installation guidelines recommend specific preparations, tools, and procedures to ensure the pump is correctly fitted and aligned with other engine components. The pump integrates seamlessly with the diesel engine system, working in conjunction with injectors, sensors, and the engine control unit to deliver optimal performance. Careful attention to installation details ensures that the pump operates efficiently and reliably 4.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps include leaks, misfires, and irregular engine performance. Troubleshooting these issues involves a systematic approach to identify the root cause. For leaks, inspecting seals and connections for wear or damage is necessary. Misfires may require checking the fuel delivery timing and pressure. Irregular engine performance could indicate a need for cleaning or replacing worn components. Addressing these issues promptly helps maintain the pump’s efficiency and prolong its service life 1.

Maintenance Tips

Routine maintenance practices are essential for ensuring the longevity and optimal performance of the Cummins 3946135 Fuel Injection Pump. Regular inspection intervals should be observed to check for wear, leaks, or other signs of deterioration. Cleaning procedures, such as flushing the fuel system to remove contaminants, are recommended to prevent buildup that can affect performance. Replacing wear parts, such as seals and gaskets, at specified intervals helps maintain the pump’s integrity and efficiency 2.

Cummins Corporation

Cummins Inc. is a renowned leader in the diesel engine industry, with a rich history of innovation and quality. The company offers a wide range of products, including engines, filtration systems, and power generation equipment. Cummins is committed to advancing technology and providing solutions that meet the evolving needs of its customers. The company’s reputation for reliability, performance, and customer satisfaction underscores its position as a trusted provider in the diesel engine market 3.

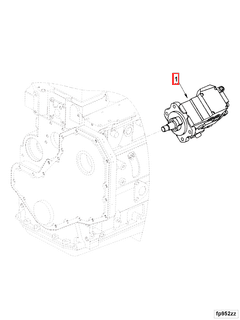

Cummins Fuel Injection Pump 3946135 Compatibility

The Cummins Fuel Injection Pump part number 3946135 is designed to integrate seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of heavy-duty applications, providing precise fuel delivery and consistent power output.

ISB CM550 Engines

The ISB CM550 engine series is one of the prominent recipients of the 3946135 fuel injection pump. This engine is known for its robust construction and high efficiency, making it a popular choice in various industrial and commercial applications. The 3946135 pump is specifically tailored to work with the ISB CM550, ensuring that it delivers the necessary fuel pressure and timing required for the engine’s optimal operation 4.

Integration and Performance

The integration of the 3946135 fuel injection pump with the ISB CM550 engine involves precise alignment and secure mounting. This ensures that the pump can effectively manage the fuel flow, which is critical for the engine’s performance. The pump’s design allows for smooth operation, reducing wear and tear on engine components and enhancing the overall lifespan of the engine 1.

Reliability and Maintenance

One of the key benefits of using the 3946135 fuel injection pump with the ISB CM550 engine is its reliability. This pump is built to withstand the rigors of continuous operation, providing consistent performance even under demanding conditions. Regular maintenance of the pump is essential to ensure that it continues to function correctly, which includes periodic inspections and timely replacement of any worn-out components 2.

Role of Part 3946135 Fuel Injection Pump in Engine Systems

The part 3946135 Fuel Injection Pump is an integral component within the engine system, ensuring precise fuel delivery to the combustion chambers. This part works in concert with several other components to optimize engine performance, efficiency, and emissions.

Interaction with Key Components

-

Fuel Tank: The pump draws diesel from the fuel tank, where it is stored under low pressure.

-

Fuel Filter: Before reaching the injection pump, the fuel passes through a fuel filter. This filter removes impurities and ensures that only clean fuel enters the pump, protecting it from wear and damage.

-

Fuel Lines: The pump is connected to the fuel lines, which transport the pressurized fuel from the pump to the injectors. These lines must be robust and leak-proof to maintain consistent fuel pressure.

-

Injectors: The high-pressure fuel from the pump is delivered to the injectors. These injectors atomize the fuel into fine particles, ensuring efficient combustion within the cylinders.

-

Engine Control Unit (ECU): Modern engines often incorporate an ECU that monitors and controls the fuel injection process. The ECU sends signals to the pump to adjust fuel delivery based on engine load, speed, and other operating conditions.

-

Camshaft: In many diesel engines, the fuel injection pump is driven by the camshaft. This mechanical linkage ensures that fuel injection is synchronized with the engine’s piston movements.

-

Governor: The governor regulates the amount of fuel delivered by the pump. It maintains a consistent engine speed by adjusting the fuel supply in response to changes in load.

-

Sensors: Various sensors, such as the fuel pressure sensor and temperature sensor, provide feedback to the ECU. This data helps the ECU make real-time adjustments to the fuel injection process, enhancing performance and efficiency.

-

Return Line: Excess fuel not injected into the cylinders is returned to the fuel tank via the return line. This helps in maintaining the desired fuel pressure and temperature within the system.

By precisely controlling the fuel delivery, the part 3946135 Fuel Injection Pump plays a significant role in ensuring smooth engine operation, optimal fuel economy, and reduced emissions. Its integration with these components highlights the complexity and interdependence within modern engine systems 3.

Conclusion

The Cummins 3946135 Fuel Injection Pump is a vital component in diesel engine systems, ensuring precise fuel delivery and enhancing engine performance, efficiency, and emissions control. Its integration with various engine components and compatibility with Cummins engines like the ISB CM550 underscores its importance in the operation of commercial trucks. Regular maintenance and proper installation are crucial for maximizing the benefits of this part, ensuring reliable and efficient engine operation 4.

-

Huzij, Robert, et al. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ ↩ ↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ ↩ ↩ -

Hilgers, Michael. Transmissions and Drivetrain Design. Springer Vieweg, 2022.

↩ ↩ ↩ ↩ -

Fischer, Robert, et al. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.