3938384

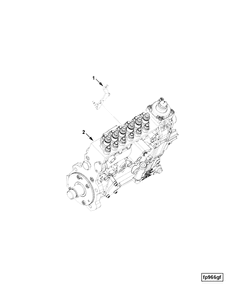

Fuel Injection Top Level Assembly Pump

Cummins®

DISCONTINUED

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fuel Injection Top Level Assembly Pump, identified by Cummins Part #3938384, is a significant component in diesel engines. Manufactured by Cummins Inc., a renowned leader in the automotive industry, this pump is integral to the efficient operation of diesel engines. Its role in delivering precise amounts of fuel to the engine ensures optimal performance and efficiency 1.

Basic Concepts of Fuel Injection Systems

Fuel injection systems in diesel engines are designed to deliver fuel directly into the combustion chamber at high pressure. The top-level assembly pump is a key component in this system, responsible for pressurizing the fuel before it is injected. Unlike other types of fuel injection systems, such as port injection or direct injection, the top-level assembly pump operates at the highest point in the fuel system, ensuring consistent fuel pressure and distribution. This setup is vital for maintaining engine performance and efficiency 2.

Purpose and Function of the Fuel Injection Top Level Assembly Pump

The Fuel Injection Top Level Assembly Pump plays a role in the operation of a truck by delivering fuel to the engine under high pressure. This ensures that the fuel is atomized properly, leading to efficient combustion. The pump’s precise control over fuel delivery helps in achieving the desired power output and fuel efficiency, making it a fundamental component in the engine’s fuel system 3.

Key Features of Cummins Fuel Injection Top Level Assembly Pump

The Cummins Fuel Injection Top Level Assembly Pump is characterized by several key features. These include precision engineering, which ensures accurate fuel delivery, and durability, designed to withstand the harsh conditions of diesel engine operation. Additionally, the pump is engineered to be compatible with specific Cummins engine models, ensuring seamless integration and optimal performance.

Benefits of Using Cummins Fuel Injection Top Level Assembly Pump

Utilizing the Cummins Fuel Injection Top Level Assembly Pump offers several advantages. These include improved fuel efficiency due to precise fuel delivery, enhanced engine performance resulting from optimal combustion, and increased reliability thanks to the pump’s robust construction. These benefits contribute to the overall efficiency and longevity of the engine.

Installation and Integration

Proper installation and integration of the Fuel Injection Top Level Assembly Pump into the truck’s fuel system are vital for its effective operation. This process involves ensuring that the pump is correctly positioned and securely mounted. Additionally, any necessary adjustments or configurations should be made to ensure that the pump operates within the specified parameters for the engine model it is intended for.

Maintenance and Troubleshooting

Routine maintenance practices are essential for ensuring the longevity and efficiency of the Fuel Injection Top Level Assembly Pump. This includes regular inspections for wear and tear, cleaning or replacing filters as needed, and checking for any signs of leaks or malfunctions. Common troubleshooting tips involve verifying the pump’s pressure output, ensuring proper fuel flow, and addressing any issues promptly to prevent further complications.

Performance Enhancements

The Fuel Injection Top Level Assembly Pump contributes significantly to overall engine performance. By ensuring precise fuel delivery, it helps in achieving optimal power output and fuel economy. Additionally, the pump plays a role in reducing emissions by promoting efficient combustion, which is beneficial for both engine performance and environmental impact.

Compatibility and Upgrades

The Cummins Fuel Injection Top Level Assembly Pump is designed to be compatible with various Cummins engine models. For those looking to enhance their engine’s performance, there are options for upgrades or modifications that can be considered. These may include performance-enhancing components or adjustments to the fuel system that can further optimize engine operation.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to innovation and quality in diesel engine components. With a rich history of providing reliable and high-performance parts, Cummins has built a reputation for excellence. Their dedication to advancing technology and maintaining high standards in manufacturing ensures that their products, like the Fuel Injection Top Level Assembly Pump, deliver exceptional performance and durability.

Application in Cummins Engines

The 3938384 Fuel Injection Top Level Assembly Pump is specifically engineered to fit seamlessly with several Cummins engine models. These engines include, but are not limited to, the following:

- 6C8.3: This engine model benefits from the precise fuel management capabilities of the 3938384 assembly pump. The pump’s design ensures that fuel is delivered at the correct pressure and timing, which is crucial for the engine’s performance and longevity.

Compatibility and Integration

The 3938384 Fuel Injection Top Level Assembly Pump is designed to integrate smoothly with the fuel systems of the aforementioned engines. Its compatibility is ensured through rigorous engineering and testing, which guarantees that it will function optimally within the specified engine architecture. This part is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance engine performance.

Importance in Engine Performance

The role of the 3938384 Fuel Injection Top Level Assembly Pump in engine performance cannot be overstated. By ensuring that fuel is delivered accurately and efficiently, this component helps to maintain the engine’s power output, fuel economy, and overall reliability. Its design and functionality are critical to the smooth operation of the engine, making it an indispensable part of the fuel injection system.

Interaction with the Fuel Pump

The Fuel Injection Top Level Assembly Pump collaborates with the primary fuel pump to maintain consistent fuel pressure within the system. While the primary fuel pump draws fuel from the tank and delivers it to the engine, the top-level assembly pump fine-tunes the pressure, ensuring that the fuel injectors receive a steady and precise flow of fuel. This synergy is essential for optimal engine performance and fuel efficiency.

Coordination with Fuel Injectors

Fuel injectors are responsible for spraying atomized fuel into the combustion chambers at the precise moment required for efficient combustion. The top-level assembly pump ensures that the fuel injectors operate under optimal pressure conditions, which is vital for achieving the correct fuel spray pattern and combustion efficiency. This coordination helps in reducing emissions and enhancing overall engine performance.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors and controls various engine parameters, including fuel delivery. The top-level assembly pump is often equipped with sensors that provide real-time data to the ECU about fuel pressure and flow rates. This information allows the ECU to make necessary adjustments to the fuel injection timing and quantity, ensuring that the engine operates within its optimal performance window.

Role in Fuel Rail Pressure Regulation

The fuel rail is a component that distributes fuel to the individual injectors. The top-level assembly pump plays a role in regulating the pressure within the fuel rail. By maintaining consistent pressure, it ensures that each injector receives an equal amount of fuel, which is crucial for balanced combustion across all cylinders. This balanced combustion is key to smooth engine operation and longevity.

Contribution to Overall Fuel System Efficiency

In summary, the Part 3938384 Fuel Injection Top Level Assembly Pump is a pivotal element in the fuel delivery system. Its role in pressure regulation, coordination with fuel injectors, and integration with the ECU underscores its importance in achieving efficient and reliable engine performance. By ensuring that the fuel system operates under optimal conditions, this component contributes significantly to the overall efficiency and effectiveness of the engine.

Conclusion

The Cummins Fuel Injection Top Level Assembly Pump, part number 3938384, is a critical component in the fuel injection system of various Cummins engines. Its precise fuel delivery capabilities ensure optimal engine performance and efficiency. The pump’s compatibility with specific Cummins engine models, its role in pressure regulation, and its integration with the ECU highlight its importance in achieving efficient and reliable engine performance. Regular maintenance and proper installation are essential for maximizing the benefits of this component.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.