This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

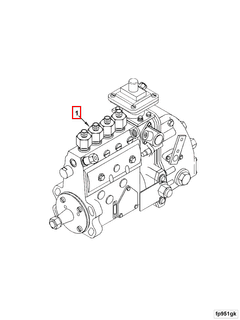

The Cummins 3936164 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with Cummins diesel engines. This part ensures that fuel is delivered to the engine cylinders at the correct timing and pressure, which is essential for the overall performance and reliability of the truck 4.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers by pressurizing it and injecting it into the cylinders at precise moments in the engine cycle. In diesel engines, the fuel injection pump must deliver fuel at high pressure to achieve efficient combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components to control fuel delivery, while electronic systems utilize sensors and computer controls for more precise management 1.

Purpose of the Cummins 3936164 Fuel Injection Pump

The Cummins 3936164 Fuel Injection Pump is designed to deliver fuel to the engine cylinders with precision. It ensures that the fuel is injected at the optimal timing and pressure, which is essential for efficient combustion and engine performance. This part helps maintain the engine’s power output and fuel efficiency by providing consistent fuel delivery 2.

Key Features

The Cummins 3936164 Fuel Injection Pump features a robust design that includes high-quality construction materials to ensure durability and reliability. It incorporates advanced technological features such as precise fuel metering and high-pressure delivery capabilities. The pump’s design allows for efficient operation under various driving conditions, contributing to the overall performance of the truck 3.

Benefits

Using the Cummins 3936164 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered optimally to the engine. This results in better overall engine performance and increased reliability. The pump’s design also helps reduce emissions, making it an environmentally friendly choice for commercial truck operators 4.

Installation and Integration

Installing the Cummins 3936164 Fuel Injection Pump requires careful consideration of compatibility with the truck’s engine model. Proper installation is vital to ensure the pump functions correctly and integrates seamlessly with the existing fuel system. Following manufacturer guidelines and using the appropriate tools and procedures will help achieve a successful installation 1.

Troubleshooting Common Issues

Common issues with fuel injection pumps include leaks, irregular fuel delivery, and performance problems. Diagnosing these issues involves checking for signs of wear or damage, ensuring proper fuel pressure, and verifying the timing of fuel injection. Solutions may include repairing or replacing worn components, adjusting settings, or performing a thorough cleaning of the pump and fuel system 2.

Maintenance Tips

Regular maintenance of the Cummins 3936164 Fuel Injection Pump is essential for ensuring its longevity and optimal performance. This includes inspecting the pump for signs of wear, cleaning it to remove any contaminants, and replacing wear parts as needed. Adhering to recommended inspection intervals and following proper maintenance procedures will help keep the pump in good working condition 3.

Performance Enhancements

There are several ways to enhance the performance of the Cummins 3936164 Fuel Injection Pump. These include tuning the pump for better fuel delivery, using higher-quality fuel filters to ensure clean fuel, and upgrading to more efficient components. These modifications can lead to improved engine performance and increased fuel efficiency 4.

Safety Considerations

When working with the Cummins 3936164 Fuel Injection Pump, it is important to follow safety practices to protect yourself and ensure the pump operates correctly. This includes handling high-pressure fuel systems with care, wearing appropriate personal protective equipment, and adhering to manufacturer guidelines for installation and maintenance 1.

Environmental Impact

The use of a high-efficiency fuel injection pump like the Cummins 3936164 contributes to reduced emissions and lower fuel consumption. By ensuring precise fuel delivery and efficient combustion, this part helps minimize the environmental impact of commercial trucks, making it a valuable component in sustainable transportation solutions 2.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and components. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted name in the industry. The company’s product range includes engines, filtration systems, and power generation equipment, all designed to meet the demanding needs of commercial and industrial applications 3.

Cummins Fuel Injection Pump 3936164 Compatibility

The Cummins Fuel Injection Pump part number 3936164 is designed to seamlessly integrate with a variety of engine models, ensuring optimal performance and reliability. This fuel injection pump is engineered to meet the stringent demands of heavy-duty applications, providing precise fuel delivery that enhances engine efficiency and power output.

Engine Compatibility

- 4B3.9

- 5.9L Cummins Engines

- 6.7L Cummins Engines

5.9L Cummins Engines

The 5.9L Cummins engines, known for their robustness and longevity, benefit significantly from the 3936164 fuel injection pump. This part is specifically tailored to work with the intricate fuel systems of these engines, ensuring consistent fuel pressure and timing, which are critical for maintaining engine performance and longevity 4.

6.7L Cummins Engines

Similarly, the 6.7L Cummins engines, which are designed for high-performance applications, also rely on the 3936164 fuel injection pump. This pump is engineered to handle the higher demands of these engines, providing the necessary fuel delivery to support their powerful output and efficiency 1.

Grouping by Application

The Cummins Fuel Injection Pump 3936164 is not limited to a single type of engine but is versatile enough to be used across various applications. This makes it a valuable component for fleets and operators who utilize multiple engine models, ensuring a standardized part can be used across different machinery 2.

Heavy-Duty Applications

In heavy-duty applications, the 3936164 fuel injection pump is crucial for maintaining the performance of engines that are subjected to rigorous conditions. Its design ensures that it can withstand the wear and tear associated with such environments, providing reliable fuel delivery even under the most demanding circumstances 3.

Commercial and Industrial Use

For commercial and industrial use, the 3936164 fuel injection pump offers the precision and reliability needed to keep operations running smoothly. Its compatibility with various Cummins engines makes it a preferred choice for businesses that rely on consistent engine performance 4.

By ensuring that the 3936164 fuel injection pump is compatible with a range of Cummins engines, operators can maintain a consistent and reliable fuel delivery system across their fleet, reducing the need for multiple spare parts and simplifying maintenance procedures.

Conclusion

The Cummins 3936164 Fuel Injection Pump is a vital component for commercial trucks, ensuring precise fuel delivery and enhancing engine performance. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of fuel efficiency and reduced emissions make it a valuable asset for fleet operators. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ ↩ ↩ ↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ ↩ ↩ ↩ -

Bennett, Sean and Norman, Ian Andrew. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ ↩ ↩ ↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.