3934425

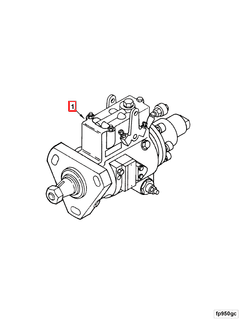

Fuel Injection Pump

Cummins®

AVAILABLE

5 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3934425 Fuel Injection Pump is a component designed for use in commercial trucks. It plays a role in the fuel delivery system by ensuring that the engine receives the precise amount of fuel needed for efficient operation. This part is integral to maintaining the performance and reliability of diesel engines in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump operates by creating high-pressure fuel that is injected into the cylinders at precise moments in the engine cycle. This process facilitates efficient combustion and power generation. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to optimize fuel injection based on engine conditions and performance requirements 1.

Purpose and Function of the 3934425 Fuel Injection Pump

The Cummins 3934425 Fuel Injection Pump is responsible for delivering fuel to the engine under high pressure. It ensures that the fuel is injected into the combustion chambers at the correct time and in the right quantity, which is important for efficient combustion and engine performance. This pump operates in conjunction with other engine components to maintain optimal fuel delivery and engine operation.

Key Features

The Cummins 3934425 Fuel Injection Pump is characterized by several key features that enhance its performance. Its design incorporates durable construction materials to withstand the rigors of heavy-duty use. The pump features precise engineering to ensure accurate fuel delivery and is equipped with technological advancements that improve efficiency and reliability. These features contribute to the pump’s ability to deliver consistent performance in demanding applications.

Benefits of Using the 3934425 Fuel Injection Pump

Utilizing the Cummins 3934425 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in an optimal manner. This results in better engine performance and reduced fuel consumption. Additionally, the pump’s reliable operation enhances the overall reliability of the engine, leading to increased uptime and reduced maintenance costs.

Common Issues and Troubleshooting

Fuel injection pumps, including the Cummins 3934425, may encounter issues over time. Common problems include fuel delivery inconsistencies, leaks, and mechanical failures. Symptoms of these issues may include engine misfires, reduced power, or difficulty starting the engine. Diagnosing these problems often involves inspecting the pump for signs of wear, checking fuel lines for leaks, and ensuring that the pump is properly calibrated. Troubleshooting may require adjusting the pump’s settings, repairing leaks, or replacing worn components to restore optimal performance 2.

Maintenance and Care

Regular maintenance is vital to ensuring the longevity and performance of the Cummins 3934425 Fuel Injection Pump. This includes periodic inspections to check for wear and damage, cleaning the pump and its components to remove contaminants, and replacing wear parts as needed. Adhering to recommended maintenance schedules helps prevent issues and ensures that the pump operates efficiently.

Integration with Engine Management Systems

The Cummins 3934425 Fuel Injection Pump is designed to integrate with modern engine management systems. This integration allows for precise control of fuel delivery based on engine conditions and performance requirements. Calibration and tuning of the pump are important to ensure that it operates in harmony with the engine management system, optimizing fuel efficiency and engine performance.

Historical Development and Technological Advancements

The evolution of fuel injection technology has led to significant advancements in pump design and functionality. The development of the Cummins 3934425 Fuel Injection Pump is a result of these advancements, incorporating features that improve efficiency, reliability, and performance. Understanding the historical context of fuel injection technology provides insight into the pump’s design and capabilities 3.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a history of innovation and quality in the automotive industry. The company’s commitment to advancing engine technology is evident in its product offerings, including the Cummins 3934425 Fuel Injection Pump. Cummins’ focus on research and development ensures that its products meet the demands of modern commercial applications, providing reliable and efficient solutions for diesel engine operation.

Compatibility of Cummins Fuel Injection Pump 3934425

The Cummins Fuel Injection Pump part number 3934425 is designed to integrate seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is specifically engineered to meet the demands of the 6B5.9 engine, providing precise fuel delivery and efficient combustion.

For the 6B5.9 engine, the 3934425 fuel injection pump is a critical component that ensures the engine operates at peak efficiency. The pump’s design allows for precise control over fuel delivery, which is essential for maintaining the engine’s performance and longevity.

When considering the compatibility of the 3934425 fuel injection pump with other Cummins engines, it is important to note that this part is tailored to work specifically with the 6B5.9 engine. While it may not be directly compatible with other engine models, Cummins offers a range of fuel injection pumps designed for various engine types, ensuring that each engine receives the appropriate fuel management system.

The 3934425 fuel injection pump is part of a broader family of Cummins components that are engineered to work together, providing a cohesive and reliable system for the 6B5.9 engine. This compatibility ensures that the engine can achieve the desired performance metrics, whether in heavy-duty applications or other demanding environments.

Role of Part 3934425 Fuel Injection Pump in Engine Systems

The part 3934425 Fuel Injection Pump is integral to the operation of various engine systems, ensuring efficient and precise fuel delivery. This component interfaces with several key systems to optimize engine performance.

Integration with Fuel System

The Fuel Injection Pump works in conjunction with the fuel system to deliver pressurized fuel to the engine’s combustion chambers. It receives fuel from the fuel tank via the fuel lines and filters, ensuring that any impurities are removed before the fuel reaches the pump. The pump then pressurizes the fuel, which is subsequently delivered to the injectors. These injectors atomize the fuel into a fine mist, allowing for better air-fuel mixture and more efficient combustion.

Interaction with Engine Control Unit (ECU)

Modern engines are equipped with an Engine Control Unit (ECU) that monitors and adjusts various parameters to ensure optimal performance. The Fuel Injection Pump communicates with the ECU to receive signals regarding the required fuel pressure and delivery rate. This real-time data exchange allows the ECU to make instantaneous adjustments based on driving conditions, load, and other variables, ensuring that the engine operates within its optimal range.

Coordination with Injectors

The pressurized fuel from the Fuel Injection Pump is delivered to the injectors, which are responsible for spraying the fuel into the combustion chambers. The timing and duration of fuel injection are controlled by the ECU, which sends signals to the injectors based on engine speed, load, and other factors. The Fuel Injection Pump must deliver a consistent and precise amount of fuel to ensure that the injectors can perform their function effectively.

Role in Emission Control Systems

Efficient fuel delivery is also essential for reducing emissions. The Fuel Injection Pump helps maintain a precise air-fuel ratio, which is critical for minimizing the production of harmful pollutants. By ensuring that the fuel is atomized correctly and delivered at the right time, the pump contributes to lower emissions and better compliance with environmental regulations.

Support from Ancillary Systems

The operation of the Fuel Injection Pump is supported by ancillary systems such as the fuel filter, fuel pressure regulator, and fuel return lines. The fuel filter ensures that any contaminants are removed from the fuel before it reaches the pump, while the fuel pressure regulator maintains consistent pressure levels. The fuel return lines allow excess fuel to be redirected back to the tank, preventing over-pressurization and ensuring stable operation.

Conclusion

In summary, the part 3934425 Fuel Injection Pump is a key component that interacts with various engine systems to ensure efficient and precise fuel delivery, ultimately contributing to optimal engine performance and reduced emissions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.