This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

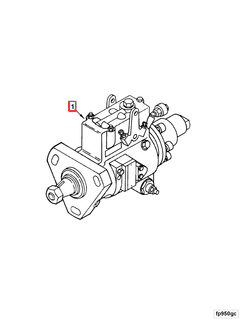

The Cummins 3933107 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. It ensures that the engine receives the precise amount of fuel needed for optimal performance, contributing to both power output and fuel efficiency 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is designed to deliver fuel to the engine’s combustion chambers by pressurizing it and injecting it at precise moments to optimize combustion. In diesel engines, this pump controls the timing and amount of fuel injected, directly affecting engine performance and efficiency 2.

Role of the Cummins 3933107 Fuel Injection Pump in Truck Operation

This Cummins part is engineered to deliver fuel to the engine of commercial trucks, ensuring that fuel is injected at the correct pressure and timing. This is essential for the engine’s combustion process and contributes to the overall operation of the truck by providing consistent and reliable fuel delivery under various operating conditions 3.

Key Features of the Cummins 3933107 Fuel Injection Pump

The 3933107 boasts several key features that enhance its performance and durability. Its design incorporates advanced technology for precise fuel delivery, and it is constructed using high-quality materials resistant to wear and corrosion. Additionally, it includes features for easy maintenance and adjustment, facilitating its use in commercial applications.

Benefits of Using the Cummins 3933107 Fuel Injection Pump

Utilizing this part offers several advantages. It contributes to improved fuel efficiency by ensuring optimal fuel delivery, resulting in better overall performance and reduced fuel consumption. Its reliable operation enhances the truck’s reliability, minimizing the risk of engine-related issues. Furthermore, its advanced design helps in reducing emissions, contributing to a cleaner operation.

Troubleshooting Common Issues with Fuel Injection Pumps

When dealing with fuel injection pumps, it is important to be aware of common issues that may arise. Symptoms such as difficulty starting the engine, irregular idling, or a decrease in power output can indicate problems with the pump. Regular inspections and maintenance can help identify these issues early. Solutions may involve cleaning the pump, replacing worn components, or adjusting the pump’s settings to restore optimal performance.

Maintenance Tips for Fuel Injection Pumps

To ensure the longevity and optimal performance of fuel injection pumps, regular maintenance is recommended. This includes inspecting the pump for signs of wear or damage, cleaning it to remove any contaminants, and lubricating moving parts to reduce friction. Additionally, following the manufacturer’s guidelines for maintenance intervals and procedures can help prevent issues and ensure the pump operates efficiently.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer known for its diesel engines and related components. With a history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality products that meet the demanding requirements of commercial applications. The company’s focus on research and development ensures that its products, including the 3933107, incorporate the latest technological advancements for enhanced performance and reliability.

Cummins Fuel Injection Pump 3933107 Compatibility

The Cummins Fuel Injection Pump part number 3933107 is designed to be compatible with a range of Cummins engines, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of various industrial and commercial applications, providing precise fuel delivery and efficient combustion.

Engine Compatibility

-

4B3.9 Series Engines

- The 3933107 fuel injection pump is specifically tailored for the 4B3.9 series engines. These engines are known for their robust construction and high performance, making them suitable for heavy-duty applications. The compatibility ensures that the pump can handle the specific fuel requirements and operational conditions of the 4B3.9 engines.

-

Other Cummins Engines

- While the primary focus is on the 4B3.9 series, the 3933107 fuel injection pump may also be compatible with other Cummins engines that share similar design and operational parameters. This versatility allows for broader application across different engine models, providing a reliable solution for various engine configurations.

Installation and Integration

-

Precision Engineering

- The 3933107 fuel injection pump is designed with precision engineering to ensure a seamless fit and function within the engine’s fuel system. This includes precise tolerances and compatibility with the engine’s fuel lines, connectors, and other related components.

-

Ease of Installation

- Installation of the 3933107 fuel injection pump is straightforward, thanks to its standardized design. Technicians can expect a hassle-free process, minimizing downtime and ensuring that the engine can return to operation quickly.

Performance and Reliability

-

Enhanced Fuel Efficiency

- By providing accurate and consistent fuel delivery, the 3933107 fuel injection pump helps improve the overall fuel efficiency of the engine. This results in better performance and reduced fuel consumption, contributing to cost savings over time.

-

Durability and Longevity

- Built to withstand the rigors of heavy-duty use, the 3933107 fuel injection pump is designed for durability and longevity. This ensures that it can maintain performance and reliability even under demanding conditions, reducing the need for frequent replacements and maintenance.

Application Across Industries

-

Industrial and Commercial Use

- The 3933107 fuel injection pump is ideal for a wide range of industrial and commercial applications. Whether in construction, agriculture, or transportation, this pump provides the necessary performance and reliability to meet the demands of these sectors.

-

Versatile Compatibility

- The versatility of the 3933107 fuel injection pump allows it to be used in various engine models, providing a flexible solution for different operational needs. This makes it a valuable component for maintaining and upgrading engine systems across multiple industries.

Role of Part 3933107 Fuel Injection Pump in Engine Systems

This part is integral to the efficient operation of various engine systems. It works in conjunction with the base fuel pump to ensure a consistent and precise delivery of fuel to the engine’s combustion chambers.

When the base fuel pump delivers fuel from the tank to the injection pump, the 3933107 takes over. It pressurizes the fuel to the levels required for injection into the engine cylinders. This high-pressure fuel is then distributed to the fuel injectors, which atomize the fuel into a fine mist for optimal combustion.

The injection pump’s role extends to synchronizing with the engine’s timing system. It ensures that fuel is injected at the precise moment for each cylinder’s combustion cycle, enhancing engine performance and fuel efficiency.

Additionally, the 3933107 interacts with the engine control unit (ECU) or engine control module (ECM). These systems monitor various parameters such as engine load, speed, and temperature to adjust the fuel injection timing and quantity dynamically. This interaction allows for real-time optimization of fuel delivery, contributing to reduced emissions and improved engine responsiveness.

Conclusion

In summary, the 3933107 Fuel Injection Pump is a key component that interfaces with the base fuel pump, timing system, and engine control electronics to deliver a reliable and efficient fuel supply to the engine. Its precise fuel delivery, durability, and compatibility with various Cummins engines make it an essential part for maintaining optimal engine performance in commercial and industrial applications.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.