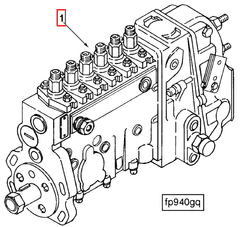

The Cummins 3927117 Fuel Injection Pump is a vital component in the operation of heavy-duty trucks. It plays a role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel needed for optimal performance. This part is designed to enhance the efficiency, power, and emissions control of diesel engines, making it a cornerstone of modern heavy-duty truck technology 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at precise moments, which is crucial for efficient combustion. In diesel engines, the fuel injection pump plays a key role in determining the engine’s performance and emissions. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 2.

Purpose of the Cummins 3927117 Fuel Injection Pump

The Cummins 3927117 Fuel Injection Pump is integral to the operation of a truck’s engine. It ensures that fuel is delivered at the correct pressure and timing, which contributes to the engine’s performance, efficiency, and emissions control. By providing consistent and precise fuel delivery, this pump helps maintain engine power and responsiveness while reducing harmful emissions 3.

Key Features

The Cummins 3927117 Fuel Injection Pump is characterized by several key features that enhance its performance and reliability. Its design incorporates high-quality materials that withstand the rigors of heavy-duty use. The pump also features advanced technological elements, such as precise metering and robust construction, which contribute to its durability and efficiency. These features ensure that the pump can operate under a wide range of conditions, providing reliable fuel delivery 4.

Benefits

The Cummins 3927117 Fuel Injection Pump offers several advantages. It improves fuel efficiency by ensuring that fuel is delivered precisely when needed, which can lead to cost savings over time. The pump also enhances engine performance by providing consistent fuel pressure and timing, resulting in smoother operation and increased power. Additionally, it contributes to reduced emissions by optimizing the fuel injection process, helping trucks meet stringent environmental regulations. The pump’s durable construction ensures long-term reliability and reduced maintenance needs 5.

Troubleshooting and Maintenance

Common issues with the Cummins 3927117 Fuel Injection Pump may include leaks, inconsistent fuel delivery, or pump failure. Troubleshooting steps often involve checking for proper fuel pressure, inspecting for leaks, and ensuring that all connections are secure. Routine maintenance practices, such as regular inspection, cleaning, and replacement of worn components, are vital for ensuring the longevity and optimal performance of the pump. Adhering to the manufacturer’s maintenance schedule can prevent many issues and extend the pump’s service life 6.

Integration with Engine Management Systems

The Cummins 3927117 Fuel Injection Pump interacts with modern engine management systems to achieve precise fuel delivery. These systems use sensors and electronic controls to monitor engine conditions and adjust fuel injection parameters in real-time. This integration ensures that the engine operates efficiently under varying loads and conditions, optimizing performance and emissions. The precise control of fuel delivery is crucial for achieving optimal engine performance and compliance with emissions regulations 7.

Historical Development and Technological Advancements

The evolution of fuel injection technology has seen significant milestones and innovations. Early mechanical fuel injection systems have given way to more advanced electronic systems, offering greater precision and control. The development of the Cummins 3927117 Fuel Injection Pump is a result of these technological advancements, incorporating the latest innovations to provide reliable and efficient fuel delivery in heavy-duty applications 8.

Cummins Company Overview

Cummins Inc. has a long-standing reputation in the diesel engine and component manufacturing industry. Founded in 1919, the company has consistently demonstrated a commitment to innovation and quality. Cummins is known for its robust and reliable diesel engines and components, which are used in a wide range of applications, from heavy-duty trucks to industrial equipment. The company’s dedication to advancing technology and maintaining high standards of quality has earned it a respected place in the industry 9.

Compatibility

The Cummins Fuel Injection Pump part number 3927117 is designed to fit seamlessly within a range of engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of various Cummins engines, providing precise fuel delivery and enhancing overall engine efficiency.

Engine Compatibility

-

6C8.3 Engines

- The 3927117 fuel injection pump is specifically tailored for the 6C8.3 engine series. This compatibility ensures that the pump’s design aligns with the engine’s requirements for fuel delivery, pressure, and timing. The precision engineering of this part guarantees smooth operation and longevity of the engine.

-

Other Cummins Engines

- While the primary focus here is on the 6C8.3 engines, the 3927117 fuel injection pump is also compatible with other Cummins engine models. This versatility makes it a valuable component for various applications, providing a reliable solution for maintaining engine performance across different platforms.

Key Features

- Precision Engineering: The 3927117 fuel injection pump is crafted with high precision to ensure accurate fuel delivery, which is critical for maintaining engine performance and efficiency.

- Durability: Built to withstand the rigors of heavy-duty applications, this pump offers durability and reliability, reducing the need for frequent replacements and maintenance.

- Compatibility: Designed to fit multiple Cummins engine models, this part offers flexibility for various applications, making it a versatile choice for engine maintenance and repair.

By integrating the 3927117 fuel injection pump into compatible Cummins engines, users can expect enhanced performance, improved fuel efficiency, and a reduction in maintenance needs. This compatibility ensures that the pump works in harmony with the engine, providing a seamless and efficient operation.

Role of Part 3927117 Fuel Injection Pump in Engine Systems

The Part 3927117 Fuel Injection Pump is an integral component within the engine system, working in concert with other elements to ensure optimal engine performance.

Integration with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the Fuel Injection Pump. The Fuel Injection Pump then takes over, pressurizing the fuel to the levels required for injection into the engine’s combustion chambers. This pressurized fuel is essential for achieving the precise fuel-air mixture needed for efficient combustion.

Coordination with Fuel Injectors

Once pressurized by the Fuel Injection Pump, the fuel is distributed to the Fuel Injectors. These injectors atomize the fuel into a fine mist, ensuring a thorough mix with the air intake. The timing and quantity of fuel delivery are meticulously controlled, directly influencing engine power, efficiency, and emissions.

Interaction with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a pivotal role in regulating the Fuel Injection Pump. By receiving data from various sensors, the ECU adjusts the pump’s operation to maintain optimal fuel delivery under varying engine loads and conditions. This dynamic adjustment ensures that the engine operates within its performance parameters while minimizing fuel consumption and emissions.

Synergy with the Common Rail System

In engines equipped with a Common Rail Fuel System, the Fuel Injection Pump is responsible for maintaining high-pressure fuel in the common rail. This system allows for more precise control over fuel injection timing and quantity, enhancing overall engine performance and fuel economy.

Contribution to Turbocharging Systems

In turbocharged engines, the Fuel Injection Pump must deliver fuel at pressures that compensate for the increased air density from the turbocharger. This ensures that the fuel-air mixture remains optimal, preventing issues such as knocking or inefficient combustion.

Role in Direct Injection Systems

For engines with Direct Injection Systems, the Fuel Injection Pump must provide even higher pressure to inject fuel directly into the combustion chamber. This direct injection method improves fuel atomization and combustion efficiency, leading to better performance and lower emissions.

Conclusion

In summary, the Part 3927117 Fuel Injection Pump is a key player in the fuel delivery system, ensuring that fuel is pressurized and delivered with precision to meet the demands of modern engine technologies. Its integration with various engine components and systems highlights its critical role in maintaining optimal engine performance, efficiency, and emissions control.

-

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing Limited, 2011.

↩ -

Giancarlo Genta and Lorenzo Morello, The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition, Springer, 2019.

↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems, Wiley, 2022.

↩ -

Tom Denton and Hayley Pells, Automotive Technician Training Theory, Routledge, 2022.

↩ -

General Information, Bulletin Number 3810248, Operation and Maintenance Manual.

↩ -

General Information, Bulletin Number 3810248, Operation and Maintenance Manual.

↩ -

Pedram Asef, Sanjeevikumar Padmanaban, and Andrew Lapthorn, Modern Automotive Electrical Systems, Wiley, 2022.

↩ -

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing Limited, 2011.

↩ -

General Information, Bulletin Number 3810248, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.