The Cummins 3925575 Fuel Injection Pump is a vital component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This pump plays a significant role in the fuel delivery system, ensuring that the engine receives the precise amount of fuel at the correct pressure and timing for optimal performance 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at specific intervals. In diesel engines, the fuel injection pump is crucial for efficient combustion and power generation. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 2.

Purpose of the Cummins 3925575 Fuel Injection Pump

The Cummins 3925575 Fuel Injection Pump is designed to deliver fuel to the engine at precise timing and pressure. This ensures efficient combustion, which is vital for the engine’s performance and fuel economy. The pump’s role is to maintain consistent fuel delivery, regardless of engine load or speed, thereby supporting the engine’s overall efficiency and reliability 3.

Key Features

The Cummins 3925575 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials. It incorporates advanced technological features such as precise fuel metering and electronic control capabilities, which enhance its performance and durability. The pump’s construction ensures it can withstand the demanding conditions of commercial truck operations.

Benefits

The Cummins 3925575 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring precise fuel delivery, the pump helps to optimize the engine’s combustion process, leading to better fuel economy and reduced emissions. Additionally, its robust design and advanced features contribute to the overall reliability and longevity of the engine.

Operational Mechanism

The Cummins 3925575 Fuel Injection Pump operates through a series of stages that include fuel delivery, pressure regulation, and timing control. Fuel is drawn from the tank and pressurized by the pump. It is then delivered to the injectors at specific intervals, controlled by the pump’s timing mechanism. This precise control over fuel delivery is crucial for maintaining engine performance and efficiency.

Integration with Engine Systems

The Cummins 3925575 Fuel Injection Pump integrates seamlessly with other engine systems, such as the Engine Control Unit (ECU) and the overall fuel system. The ECU monitors various engine parameters and adjusts the fuel injection timing and pressure as needed to optimize performance. This integration ensures that the engine operates efficiently under a wide range of conditions.

Common Issues and Troubleshooting

Common issues with the Cummins 3925575 Fuel Injection Pump may include fuel delivery inconsistencies, pressure fluctuations, and timing errors. Troubleshooting steps may involve checking for leaks, inspecting the pump’s mechanical components, and ensuring proper electrical connections. Regular maintenance and timely repairs can help prevent these issues and ensure the pump’s optimal performance.

Maintenance Tips

Regular maintenance practices are essential for ensuring the longevity and optimal performance of the Cummins 3925575 Fuel Injection Pump. This includes routine inspections, cleaning, and the replacement of worn-out components. Adhering to the manufacturer’s maintenance schedule and using high-quality fuel and lubricants can also contribute to the pump’s reliable operation.

Upgrades and Modifications

Possible upgrades or modifications to the Cummins 3925575 Fuel Injection Pump can enhance its performance or address specific operational needs. These may include installing performance injectors, upgrading the ECU for better control, or modifying the pump for higher fuel pressures. Such enhancements can improve engine performance, fuel efficiency, and overall reliability.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, the company has grown to become a reputable name in the diesel engine and component manufacturing industry. Cummins is known for its innovation, quality, and commitment to customer satisfaction, making it a preferred choice for commercial truck operators worldwide.

Cummins Fuel Injection Pump 3925575 Compatibility

The Cummins Fuel Injection Pump part number 3925575 is designed to fit seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of heavy-duty applications, providing precise fuel delivery and efficient combustion.

Engine Compatibility

- 6C8.3: The 3925575 fuel injection pump is specifically engineered to work with the 6C8.3 engine. This engine is known for its robust construction and high power output, making it suitable for demanding industrial and commercial applications. The pump’s design ensures that it can handle the high pressures and flow rates required by this engine, contributing to its overall efficiency and longevity.

Grouping of Engines

For engines within the same family or series, the 3925575 fuel injection pump offers a versatile solution. Its compatibility extends to other engines within the same group, ensuring that users can rely on a single part number for multiple applications. This not only simplifies inventory management but also ensures that the same high standards of performance and reliability are maintained across different engine models.

Key Features

- Precision Engineering: The pump is meticulously designed to deliver fuel with pinpoint accuracy, ensuring optimal combustion and performance.

- Durability: Built to withstand the rigors of heavy-duty use, the 3925575 pump is constructed from high-quality materials that resist wear and tear.

- Ease of Installation: The pump is engineered for straightforward installation, reducing downtime and maintenance costs.

- Compatibility: Designed to fit a range of engine models, the 3925575 pump offers a versatile solution for various applications.

By choosing the Cummins Fuel Injection Pump part number 3925575, users can be confident in the pump’s ability to deliver reliable performance and efficiency across a range of engine models.

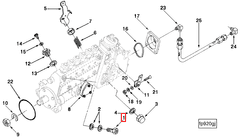

Role of Part 3925575 Fuel Injection Pump in Engine Systems

The part 3925575 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines. This component works in conjunction with several other parts to ensure optimal fuel delivery and combustion.

Integration with the Fuel System

-

Fuel Tank: The journey of fuel begins in the fuel tank, where it is stored until needed. The fuel injection pump draws fuel from the tank via the fuel lines.

-

Fuel Lines: These lines transport fuel from the tank to the injection pump. The integrity and cleanliness of these lines are essential for maintaining consistent fuel pressure and flow.

-

Fuel Filter: Before reaching the injection pump, fuel passes through a filter that removes impurities. This ensures that only clean fuel enters the pump, preventing damage and ensuring efficient operation.

Operation within the Engine System

-

Fuel Injection Pump: Part 3925575 pressurizes the fuel and delivers it to the injectors at precise moments. This timing is critical for efficient combustion and overall engine performance.

-

Fuel Injectors: The pressurized fuel is then sprayed into the combustion chamber through the injectors. The injection pump’s precision timing ensures that fuel is delivered at the optimal moment in the engine cycle.

-

Combustion Chamber: Within the combustion chamber, the atomized fuel mixes with air and ignites, driving the piston downward and generating power.

-

Exhaust System: Post-combustion, the exhaust gases are expelled through the exhaust system. Efficient fuel injection directly impacts the quality of combustion, thereby influencing emissions and engine performance.

Supporting Components

-

Engine Control Unit (ECU): Modern engines often use an ECU to monitor and adjust the fuel injection process in real-time. The fuel injection pump must be compatible with ECU signals to ensure precise fuel delivery.

-

Sensors: Various sensors, such as the crankshaft position sensor and oxygen sensor, provide data to the ECU, allowing it to make necessary adjustments to the fuel injection timing and quantity.

-

Turbocharger: In turbocharged engines, the fuel injection pump must accommodate the increased air volume, ensuring that fuel delivery matches the higher airflow for optimal performance.

By understanding how part 3925575 Fuel Injection Pump interacts with these components, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 3925575 Fuel Injection Pump is a critical component in the efficient operation of diesel engines, particularly in commercial trucks. Its precise fuel delivery, robust design, and compatibility with various engine models make it a reliable choice for heavy-duty applications. Regular maintenance and understanding its integration with other engine systems are essential for ensuring optimal performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.