The Cummins 3925086 Fuel Injection Pump is a vital component in the operation of commercial trucks, playing a significant role in the fuel delivery system. This part is designed to deliver precise amounts of fuel to the engine’s combustion chambers, ensuring optimal performance and efficiency. Its importance lies in its ability to maintain the correct fuel pressure and timing, which are essential for the engine’s operation 4.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the pump operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at precise moments in the engine cycle. This process ensures efficient combustion, which is essential for engine performance 1. The principles of fuel injection involve delivering the right amount of fuel at the right time and pressure to achieve optimal combustion efficiency and reduce emissions 2.

Purpose of the Cummins 3925086 Fuel Injection Pump

The Cummins 3925086 Fuel Injection Pump is specifically designed to enhance the operation of trucks by ensuring that fuel is delivered to the engine in a controlled and efficient manner. This pump contributes to engine performance by providing the necessary fuel pressure and timing for combustion. It also plays a role in fuel efficiency by ensuring that fuel is used effectively, and in emissions control by promoting cleaner combustion 3.

Key Features

The Cummins 3925086 Fuel Injection Pump features a robust design and is constructed from high-quality materials to ensure durability and reliability. Its technological advancements include precise fuel metering and advanced injection timing, which contribute to its efficiency. Unique characteristics of this pump include its ability to adapt to varying engine loads and conditions, ensuring consistent performance across different operating scenarios 4.

Benefits

The Cummins 3925086 Fuel Injection Pump offers several benefits, including improved fuel economy due to its efficient fuel delivery system. It also enhances engine performance by ensuring optimal combustion, which leads to increased power and responsiveness. Additionally, the pump contributes to reduced emissions by promoting cleaner burning fuel, and it increases reliability through its durable construction and advanced technology. These benefits have a positive impact on truck operation and fleet management by reducing maintenance costs and improving overall efficiency 3.

Troubleshooting and Maintenance

Common issues with the Cummins 3925086 Fuel Injection Pump may include fuel delivery problems, such as inconsistent fuel pressure or timing. Troubleshooting steps may involve checking for leaks, inspecting the pump for wear, and ensuring that the fuel system is clean and free of contaminants. Routine maintenance practices include regular inspection of the pump and its components, cleaning or replacing filters, and ensuring that all connections are secure. Identifying signs of wear or malfunction, such as decreased engine performance or unusual noises, can help in maintaining the pump’s optimal performance and longevity 4.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the industry for producing high-quality diesel engines and related components. The company has a history of innovation and commitment to quality, which is reflected in its products, including the Cummins 3925086 Fuel Injection Pump. Cummins’ role as a leading manufacturer is underscored by its dedication to advancing diesel technology and providing reliable, efficient solutions for commercial vehicle operators 4.

Compatibility

The Cummins Fuel Injection Pump part number 3925086 is designed to fit seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent requirements of Cummins engines, providing precise fuel delivery and efficient combustion. Below is a detailed overview of the engines and engine groups that this fuel injection pump is compatible with:

Engine Models

- 6B5.9

- Other Cummins Engines

Engine Groups

- Cummins B Series Engines

- The 3925086 fuel injection pump is specifically tailored for the B Series engines, which include the 6B5.9. This series is known for its robust design and high performance, making it a popular choice in various applications.

- Cummins C Series Engines

- While the 3925086 is not exclusively for the C Series, it is compatible with certain models within this series, ensuring that the pump meets the needs of a broader range of Cummins engines.

- Cummins K Series Engines

- The fuel injection pump is also suitable for select K Series engines, providing a reliable solution for maintaining the engine’s efficiency and power output.

By ensuring compatibility with these engine models and groups, the Cummins Fuel Injection Pump 3925086 guarantees that users can maintain their engines’ performance without the need for custom modifications. This compatibility is crucial for technicians and fleet managers who rely on consistent and reliable engine performance 4.

Role of Part 3925086 Fuel Injection Pump in Engine Systems

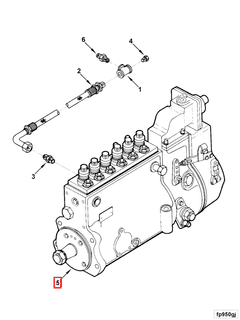

The Part 3925086 Fuel Injection Pump is an integral component within the Bosch injection system, ensuring precise fuel delivery to the engine. This pump works in concert with several other components to optimize engine performance and efficiency.

Integration with Bosch Injection System

-

Fuel Supply Line: The pump is connected to the fuel supply line, which delivers fuel from the tank to the pump. The pump then pressurizes the fuel to the required levels for injection.

-

Injectors: Once pressurized, the fuel is directed to the injectors. The pump’s role is to maintain consistent pressure, ensuring that the injectors can atomize the fuel properly for combustion.

-

Control Unit: The Bosch injection system includes an electronic control unit (ECU) that communicates with the fuel injection pump. The ECU monitors various engine parameters and adjusts the pump’s operation to maintain optimal fuel delivery.

-

Sensors: Multiple sensors, such as the engine speed sensor and fuel pressure sensor, provide feedback to the ECU. The pump responds to these signals to adjust fuel delivery in real-time.

-

Return Line: Excess fuel not used during injection is sent back to the tank via the return line. The pump manages this return flow to prevent fuel wastage and maintain system pressure.

-

Filter System: The fuel passes through a filter before reaching the pump, ensuring that any contaminants are removed. The pump relies on clean fuel to operate efficiently and prevent wear.

-

Camshaft: In mechanically driven systems, the pump is often connected to the engine’s camshaft. This linkage ensures that fuel delivery is synchronized with the engine’s operation.

-

Governor: The governor regulates the pump’s output based on engine load and speed. It plays a key role in maintaining consistent fuel delivery across varying operating conditions.

By coordinating with these components, the Part 3925086 Fuel Injection Pump ensures that the engine receives the precise amount of fuel needed for efficient and reliable operation 4.

Conclusion

The Cummins 3925086 Fuel Injection Pump is a critical component in the fuel delivery system of commercial trucks. Its robust design, precise fuel metering, and advanced injection timing contribute to enhanced engine performance, improved fuel efficiency, and reduced emissions. Regular maintenance and troubleshooting are essential to ensure the longevity and optimal performance of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of this fuel injection pump, making it a reliable choice for commercial vehicle operators.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩ ↩ -

Mollenhauer, Klaus, and Helmut Tschoeke. Handbook of Diesel Engines. Springer, 2010.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.