This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Fuel Shutoff Valve Lever, identified by part number 3924443, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This Cummins part plays a significant role in the operational dynamics of heavy-duty trucks, particularly in the management of fuel delivery to the engine. Understanding its function and importance is key to maintaining efficient and safe truck operations.

Basic Concepts of Fuel Shutoff Valve Lever

The Fuel Shutoff Valve Lever operates on the fundamental principle of controlling the flow of fuel to the engine. By actuating this lever, operators can open or close the valve, thereby regulating the amount of fuel that reaches the engine. This mechanism is crucial for starting, stopping, and modulating the engine’s operation, ensuring that the truck operates within desired parameters 1.

Purpose and Function

The primary role of the Fuel Shutoff Valve Lever in truck operations is to provide a manual means of controlling fuel flow to the engine. This control is vital for engine management, allowing for precise adjustments to engine performance. Additionally, the lever serves as a safety feature, enabling operators to quickly shut off fuel in emergency situations, thereby preventing potential engine damage or hazardous conditions 2.

Key Features

The Fuel Shutoff Valve Lever is designed with several features that enhance its performance and durability. It is constructed from high-quality materials to withstand the rigors of heavy-duty truck environments. The lever’s design ensures easy operation and precise control over fuel flow. Additionally, it may include features such as corrosion resistance and compatibility with various fuel types, contributing to its reliability and longevity.

Benefits

Incorporating the Fuel Shutoff Valve Lever into a truck’s fuel system offers several advantages. It allows for improved engine control, enabling operators to fine-tune engine performance for specific tasks or conditions. Enhanced safety measures are another benefit, as the lever provides a quick and effective way to shut off fuel in emergencies. Furthermore, proper use of the lever can contribute to fuel efficiency by allowing for more precise control over fuel delivery.

Installation and Integration

Proper installation and integration of the Fuel Shutoff Valve Lever within a truck’s fuel system are crucial for its effective operation. Installation should follow manufacturer guidelines to ensure compatibility and correct function. It is important to consider factors such as the orientation of the lever, secure mounting, and proper connection to the fuel system to avoid leaks or malfunctions.

Troubleshooting and Maintenance

Common issues with the Fuel Shutoff Valve Lever may include difficulty in operation, leaks, or failure to shut off fuel completely. Troubleshooting these issues often involves checking for obstructions, ensuring proper installation, and inspecting for wear or damage. Regular maintenance, such as cleaning and lubrication, can help prevent these issues and ensure optimal performance and longevity of the lever.

Safety Considerations

When working with the Fuel Shutoff Valve Lever, it is important to adhere to safety protocols. This includes proper handling procedures to avoid injury or damage to the component. Operators should be aware of potential hazards, such as fuel leaks or improper shutoff, and take appropriate measures to mitigate these risks. Training on the correct use and maintenance of the lever is also recommended to ensure safe and effective operation.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a rich history and a strong reputation for reliability and innovation, Cummins continues to be a leader in the field, providing solutions that enhance the performance, efficiency, and safety of vehicles. The Fuel Shutoff Valve Lever is a testament to Cummins’ dedication to excellence in automotive component manufacturing 3.

Compatibility

The Fuel Shutoff Valve Lever is compatible with the following Cummins engine models:

- 6B5.9 Series

This part is engineered to fit seamlessly within the 6B5.9 engine series, providing reliable control over the fuel shutoff function. Its design ensures compatibility with the specific architecture and operational requirements of these engines.

Role in Engine Systems

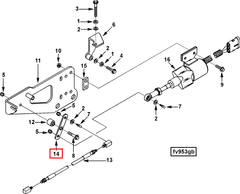

The Fuel Shutoff Valve Lever is an integral component in the operation of engine systems, particularly in ensuring the precise control of fuel flow. This lever works in conjunction with several other components to maintain the engine’s efficiency and safety.

When the Fuel Shutoff Valve Lever is actuated, it interacts directly with the Fuel Shutoff Valve. This interaction allows for the opening or closing of the valve, thereby controlling the flow of fuel into the engine. The lever’s movement is typically triggered by mechanical or hydraulic means, depending on the engine design.

The Solenoid Assembly Bracket plays a supporting role in this system. It houses the solenoid, which is an electrically controlled switch used for operating a mechanical device. In this context, the solenoid can be activated to move the Fuel Shutoff Valve Lever, providing an automated means of controlling fuel flow. The bracket ensures the solenoid is securely mounted and aligned correctly with the lever.

Additionally, the integration of the Fuel Shutoff Valve Lever with the broader fuel system components ensures that fuel delivery is consistent and responsive to the engine’s demands. This lever’s precise operation is essential for maintaining optimal engine performance, especially during start-up, shut-down, and varying load conditions.

Conclusion

In summary, the Fuel Shutoff Valve Lever (part 3924443) is a key element in the fuel management system, working in harmony with the Fuel Shutoff Valve and Solenoid Assembly Bracket to ensure accurate and reliable fuel control within the engine. Its role in maintaining engine efficiency, safety, and performance underscores the importance of proper installation, maintenance, and operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.