3921978

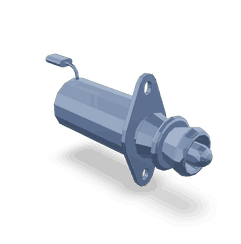

Fuel Pump Solenoid

Cummins®

AVAILABLE

7 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3921978 Fuel Pump Solenoid is a component designed to regulate the flow of fuel within the fuel system of heavy-duty trucks equipped with Cummins engines. Its purpose is to ensure that the engine receives the precise amount of fuel needed for optimal performance under varying operating conditions. The significance of this part lies in its ability to contribute to the overall efficiency and reliability of the truck’s fuel delivery system 1.

Basic Concepts of Fuel Pump Solenoids

A fuel pump solenoid is an electromechanical device that controls the flow of fuel from the fuel tank to the engine. It operates by using an electric current to move a plunger, which opens or closes a valve within the fuel line. This action allows or restricts the passage of fuel, thereby regulating the amount delivered to the engine. The solenoid interacts with the engine control unit (ECU) to adjust fuel delivery based on engine load, speed, and other operating parameters 2.

Role of the 3921978 Fuel Pump Solenoid in Truck Operation

The 3921978 Fuel Pump Solenoid plays a specific role in the fuel delivery system of Cummins engines by ensuring that fuel is delivered at the correct pressure and volume. This precise control helps maintain engine performance and efficiency, allowing the engine to operate smoothly across a range of conditions. By modulating fuel flow, the solenoid contributes to the engine’s ability to meet power demands while optimizing fuel consumption 3.

Key Features of the 3921978 Fuel Pump Solenoid

The design and construction of the 3921978 Fuel Pump Solenoid incorporate several features that enhance its reliability and performance. These include the use of high-quality materials resistant to corrosion and wear, a robust build quality that ensures durability under the demanding conditions of heavy-duty truck operation, and technological advancements that improve its efficiency and responsiveness to engine control signals.

Benefits of Using the 3921978 Fuel Pump Solenoid

Utilizing the 3921978 Fuel Pump Solenoid offers several advantages. These include improved fuel efficiency due to precise fuel delivery, enhanced engine performance as a result of optimal fuel-air mixture, and increased durability thanks to its robust construction and high-quality materials. These benefits contribute to the overall reliability and efficiency of the truck’s fuel system.

Troubleshooting Common Issues with Fuel Pump Solenoids

Identifying and addressing common problems associated with fuel pump solenoids can help maintain the efficiency and reliability of the fuel system. Symptoms of failure may include difficulty starting the engine, irregular engine performance, or decreased fuel efficiency. Diagnostic procedures may involve checking electrical connections, testing the solenoid’s operation, and inspecting the fuel system for leaks or blockages. Potential solutions range from cleaning or replacing the solenoid to addressing issues within the fuel system.

Maintenance Tips for Fuel Pump Solenoids

Routine maintenance practices can ensure the longevity and optimal performance of the 3921978 Fuel Pump Solenoid. These practices include regular inspection intervals to check for signs of wear or damage, cleaning the solenoid and its connections to prevent buildup that could affect performance, and following manufacturer recommendations for replacement or servicing. Adhering to these maintenance tips can help prevent issues and ensure the solenoid continues to operate efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. Its product range includes a variety of engines and components designed to meet the demanding requirements of commercial vehicles, contributing to the efficiency, performance, and durability of these machines.

Cummins Fuel Pump Solenoid 3921978 Compatibility

The Cummins Fuel Pump Solenoid part number 3921978 is designed to work seamlessly with various engine models, ensuring optimal fuel delivery and engine performance. This solenoid is engineered to fit within the fuel system architecture of the following Cummins engines:

- 6C8.3

This solenoid plays a role in the fuel delivery system by controlling the flow of fuel to the engine. It is engineered to ensure that the engine receives the correct amount of fuel at the right pressure, which is essential for maintaining engine efficiency and performance.

For the 6C8.3 engine, the 3921978 solenoid is specifically designed to integrate with the engine’s fuel management system. Its precise fit and reliable operation help to maintain the engine’s performance and longevity.

When replacing or servicing the fuel pump solenoid in these engines, it is important to ensure that the part number 3921978 is used, as it is specifically designed to meet the requirements of the Cummins 6C8.3 engine. This compatibility ensures that the engine continues to operate efficiently and reliably.

Role of Part 3921978 Fuel Pump Solenoid in Engine Systems

The Fuel Pump Solenoid, identified by part number 3921978, is integral to the operation of several key components within engine systems. Its primary function is to regulate the flow of fuel to the engine, ensuring that the fuel delivery is precise and efficient.

Interaction with the Valve

The Fuel Pump Solenoid works in conjunction with the valve to manage the fuel supply. When the solenoid is activated, it opens the valve, allowing fuel to flow from the fuel tank to the fuel pump. This process is essential for maintaining the correct fuel pressure within the system. The solenoid’s ability to open and close the valve swiftly ensures that the engine receives a consistent fuel supply, which is vital for smooth operation and performance.

Coordination with the Fuel Shutoff

In scenarios where the engine needs to be stopped quickly or in emergency situations, the Fuel Pump Solenoid plays a role in the fuel shutoff process. Upon receiving a signal to shut off, the solenoid deactivates, closing the valve and halting the fuel flow. This immediate action prevents fuel from reaching the engine, effectively stopping its operation. The solenoid’s rapid response is key to ensuring safety and preventing potential damage to the engine.

Overall System Integration

The integration of the Fuel Pump Solenoid with these components highlights its importance in the fuel delivery system. By precisely controlling the valve and coordinating with the fuel shutoff mechanism, the solenoid ensures that the engine operates efficiently and safely. Its reliable performance is essential for the overall functionality and reliability of the engine system.

Conclusion

The Cummins 3921978 Fuel Pump Solenoid is a critical component in the fuel delivery system of Cummins engines, ensuring precise fuel delivery and contributing to the engine’s efficiency and reliability. Understanding its role, features, and maintenance requirements can help in maintaining the optimal performance of heavy-duty trucks.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

R. Matthew Brach. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.