Introduction

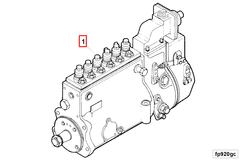

The Cummins 3921774 Fuel Injection Pump is a critical component in the engine systems of commercial trucks. It ensures the efficient operation of diesel engines by precisely delivering fuel to the combustion chambers. This part is essential for maintaining optimal engine performance, fuel efficiency, and overall truck functionality 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers pressurized fuel to the engine’s combustion chambers. It operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at precise moments in the engine cycle. The importance of fuel injection pumps in diesel engines lies in their ability to control the timing and quantity of fuel delivery, which directly impacts engine performance and efficiency. Fuel injection systems can be mechanical or electronic. Mechanical systems use physical components like cams and springs to control fuel delivery, while electronic systems utilize sensors and computer controls for more precise fuel management 2.

Purpose of the Cummins 3921774 Fuel Injection Pump

The Cummins 3921774 Fuel Injection Pump is designed to enhance the operation of a truck’s engine. It ensures that fuel is delivered at the correct pressure and timing, which contributes to improved engine performance and fuel efficiency. By maintaining precise fuel delivery, this pump helps in achieving optimal combustion, which is essential for the engine’s power output and overall functionality 3.

Key Features

The Cummins 3921774 Fuel Injection Pump boasts several key features that set it apart. Its design incorporates advanced technology to ensure reliable and efficient fuel delivery. Constructed from high-quality materials, this pump is built to withstand the rigors of commercial truck operations. Unique technological advancements in this model include enhanced precision in fuel delivery and improved durability, ensuring long-term performance and reliability 4.

Benefits

Using the Cummins 3921774 Fuel Injection Pump offers several benefits. It contributes to improved fuel efficiency by ensuring that fuel is delivered optimally, reducing waste and enhancing the engine’s performance. This pump also provides enhanced reliability and longevity, thanks to its robust construction and advanced design. Specific advantages of this model include superior fuel delivery precision and increased durability compared to other fuel injection pumps.

Installation and Integration

When installing the Cummins 3921774 Fuel Injection Pump, it is important to consider compatibility with various engine models. Proper installation involves ensuring that the pump is correctly aligned and securely fastened to prevent leaks and ensure efficient operation. Any necessary modifications or adjustments should be made according to the manufacturer’s guidelines to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with fuel injection pumps include leaks, inconsistent fuel delivery, and wear on internal components. For the Cummins 3921774 model, specific troubleshooting tips include checking for proper alignment, ensuring secure connections, and inspecting for signs of wear or damage. Regular maintenance, such as inspecting and cleaning the pump, replacing wear-prone components, and following recommended inspection intervals, is crucial for ensuring optimal performance and longevity.

Performance Optimization

To optimize the performance of the Cummins 3921774 Fuel Injection Pump, consider strategies such as tuning and upgrades. These can enhance fuel delivery, increase engine power, and improve efficiency. Modifications may include adjusting the pump’s settings for better fuel atomization or installing performance upgrades to further refine fuel delivery.

Safety Considerations

When working with the Cummins 3921774 Fuel Injection Pump, it is important to follow safety guidelines to prevent accidents. This includes ensuring proper handling during installation and maintenance, wearing appropriate personal protective equipment, and adhering to industry standards for safe operation. Regular inspections and maintenance are also crucial to identify and address potential safety hazards.

Cummins Corporation

Cummins Inc. is a renowned manufacturer in the diesel engine and component industry. With a rich history and a strong commitment to innovation, quality, and customer satisfaction, Cummins has established a reputation for producing reliable and high-performance diesel engines and components. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Cummins Fuel Injection Pump 3921774 Compatibility

The Cummins Fuel Injection Pump part number 3921774 is designed to be compatible with a variety of engine models, ensuring reliable performance and efficiency across different applications. This part is engineered to meet the stringent requirements of Cummins engines, providing precise fuel delivery and optimal engine performance.

Engine Compatibility

- 6C8.3 Engines: The 3921774 fuel injection pump is specifically engineered to fit seamlessly with the 6C8.3 engines. This compatibility ensures that the pump delivers the necessary fuel pressure and timing, enhancing the engine’s power output and fuel efficiency.

The Cummins Fuel Injection Pump 3921774 is a critical component for maintaining the performance and reliability of these engines. Its design and engineering make it an ideal choice for users seeking to optimize their engine’s fuel delivery system.

Role of Part 3921774 Fuel Injection Pump in Engine Systems

The part 3921774 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, working in conjunction with the Base Fuel Pump and the Fuel Pump to ensure optimal engine performance.

When the engine is started, the Base Fuel Pump draws fuel from the tank and delivers it to the Fuel Injection Pump. The Base Fuel Pump maintains a consistent fuel pressure, ensuring a steady supply of fuel. The Fuel Injection Pump then takes over, precisely metering the fuel and injecting it into the engine’s combustion chambers at the right time and in the right quantity.

This precise fuel delivery is essential for efficient combustion, which directly impacts engine power, fuel efficiency, and emissions. The Fuel Injection Pump’s role is to enhance the fuel atomization process, ensuring that the fuel mixes thoroughly with the air in the combustion chamber. This results in a more complete burn, which is vital for maximizing engine performance and minimizing harmful emissions.

In summary, the interplay between the Base Fuel Pump, the Fuel Pump, and the Fuel Injection Pump is designed to create a highly efficient fuel delivery system. This system ensures that the engine receives the exact amount of fuel it needs, at the precise moment it is required, contributing to overall engine efficiency and performance.

Conclusion

The Cummins 3921774 Fuel Injection Pump is a vital component for the efficient operation of diesel engines in commercial trucks. Its precise fuel delivery enhances engine performance, fuel efficiency, and overall truck functionality. With advanced features, robust construction, and compatibility with various engine models, this part ensures reliable and optimal engine performance. Regular maintenance and adherence to safety guidelines are essential for maximizing the benefits of this critical component.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011

↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015

↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.