3921377

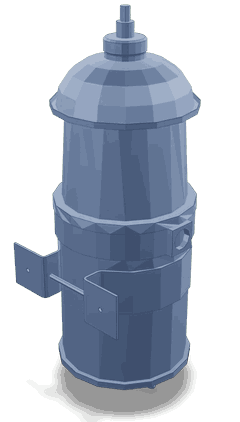

Fuel Water Separator

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3921377 Fuel-Water Separator is designed to enhance the operation of commercial trucks by ensuring the fuel delivered to the engine is free from water contamination. This part is integral to maintaining the efficiency and reliability of diesel engines, which are commonly used in heavy-duty applications 3.

Basic Concepts of Fuel-Water Separators

A fuel-water separator is a device that removes water from diesel fuel before it reaches the engine. Water can enter the fuel system through condensation or contamination during storage and transport. The presence of water in diesel fuel can lead to corrosion, reduced fuel efficiency, and engine damage. The separator works by allowing fuel to pass through a filter medium that captures water droplets, ensuring that only clean fuel enters the engine 1.

Purpose of the Cummins 3921377 Fuel-Water Separator

The Cummins 3921377 Fuel-Water Separator maintains the quality of the fuel supplied to the engine. By removing water and other contaminants, it helps to ensure consistent engine performance, prevents corrosion within the fuel system, and contributes to the overall longevity of the engine. This separator is particularly important in environments where fuel quality may be compromised 3.

Key Features

The Cummins 3921377 Fuel-Water Separator is characterized by its robust design and the use of high-quality materials. It features a durable housing that protects the internal components from external damage. The separator includes a replaceable filter element that efficiently captures water and contaminants. Additionally, it is equipped with a water drain valve, allowing for easy removal of accumulated water without disrupting the fuel flow 3.

Benefits of Using a Fuel-Water Separator

Incorporating a fuel-water separator into a truck’s fuel system offers several advantages. It contributes to improved engine efficiency by ensuring that the fuel delivered is clean and dry. This can lead to better combustion and reduced emissions. Furthermore, by preventing water-related corrosion and component wear, the separator can help lower maintenance costs and extend the engine’s operational life 2.

Installation and Integration

Proper installation of the Cummins 3921377 Fuel-Water Separator involves integrating it into the truck’s fuel system in a manner that ensures uninterrupted fuel flow and effective water separation. It may require modifications to the existing fuel lines and should be positioned in a location that allows for easy access for maintenance and water drainage. Following the manufacturer’s guidelines during installation is important to ensure optimal performance 3.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3921377 Fuel-Water Separator is important to ensure its continued effectiveness. This includes periodic inspection of the filter element for signs of contamination and replacement as necessary. The water drain valve should be used regularly to remove accumulated water. Common issues such as reduced fuel flow or increased water content in the fuel may indicate the need for filter replacement or system inspection 3.

Performance and Efficiency

The Cummins 3921377 Fuel-Water Separator contributes to overall truck performance and fuel efficiency by ensuring that the engine receives clean, dry fuel. This can result in more consistent engine operation, improved fuel economy, and reduced emissions. In real-world applications, trucks equipped with this separator may experience fewer fuel-related issues and require less frequent maintenance 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history of innovation and a strong reputation in the industry, Cummins is committed to producing high-quality products that meet the demanding requirements of commercial and industrial applications. The company’s focus on reliability, performance, and customer satisfaction has established it as a trusted name in the automotive and heavy-duty truck sectors 3.

Cummins Fuel-Water Separator Part 3921377 Compatibility

The Cummins part number 3921377, a Fuel-Water Separator, is designed to be compatible with a range of Cummins engines, including the 6B5.9 and 6C8.3 models. This part is crucial for maintaining engine performance by ensuring that the fuel supply is free from contaminants such as water and sediment.

For the 6B5.9 engine, the Fuel-Water Separator part 3921377 is engineered to fit seamlessly into the engine’s fuel system. It is positioned in the fuel line, allowing it to capture and separate water and other impurities from the fuel before it reaches the engine. This helps to prevent engine damage and ensures optimal performance.

Similarly, the 6C8.3 engine benefits from the use of the Cummins part number 3921377. This part is designed to integrate with the 6C8.3’s fuel system, providing the same essential function of removing water and contaminants from the fuel. By doing so, it helps to maintain the engine’s efficiency and longevity.

In both engines, the installation of the Fuel-Water Separator part 3921377 is straightforward and does not require any special tools or modifications. It is a straightforward replacement part that can be easily installed by following the manufacturer’s guidelines. This ensures that the engine continues to operate smoothly and reliably, free from the detrimental effects of water and sediment in the fuel 3.

Role of Part 3921377 Fuel-Water Separator in Engine Systems

The 3921377 Fuel-Water Separator is an integral component within the fuel system, ensuring the delivery of clean fuel to the engine. This separator is designed to remove water and contaminants from the fuel before it reaches the engine, thereby maintaining the efficiency and reliability of the fuel system.

Integration with Fuel System Components

-

Fuel Tank: The separator is typically installed between the fuel tank and the fuel pump. As fuel is drawn from the tank, it passes through the separator, where water and impurities are filtered out.

-

Fuel Pump: Clean fuel from the separator is then delivered to the fuel pump. This ensures that the pump operates efficiently without the risk of damage from water or contaminants.

-

Fuel Filter: Although the separator performs a primary filtration role, a secondary fuel filter may still be employed downstream to catch any remaining particles, ensuring the fuel reaching the engine is of the highest quality.

-

Fuel Injectors: The purified fuel is subsequently delivered to the fuel injectors. The absence of water and contaminants allows the injectors to operate smoothly, enhancing combustion efficiency and reducing the likelihood of injector fouling.

-

Engine: Ultimately, the role of the 3921377 Fuel-Water Separator culminates in the engine, where clean fuel contributes to optimal performance, reduced emissions, and prolonged engine life.

Interaction with Accessories

-

Fuel Gauge Sender Unit: Accurate fuel level readings are essential for efficient fuel management. The separator ensures that the fuel gauge sender unit operates in a clean environment, providing reliable readings.

-

Fuel Pressure Regulator: Consistent fuel pressure is vital for engine performance. The separator helps maintain fuel quality, which in turn supports the stable operation of the fuel pressure regulator.

-

Fuel Lines and Hoses: The separator protects fuel lines and hoses from corrosion and blockages caused by water and contaminants, ensuring a reliable fuel delivery system.

Conclusion

The Cummins 3921377 Fuel-Water Separator plays a significant role in maintaining the integrity of the fuel system, directly influencing the performance and longevity of the engine and its associated components. Regular maintenance and proper installation are essential to ensure the continued effectiveness of this part.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Fuel Filter | 1 | 3921515 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.