Introduction

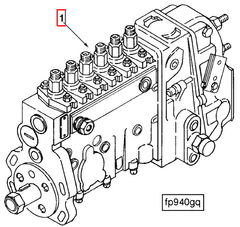

The Cummins 3921148 Fuel Injection Pump is a vital component in the operation of commercial trucks powered by Cummins engines. This pump is designed to deliver fuel to the engine cylinders with precision, ensuring optimal performance and efficiency. Its role in the fuel delivery system is significant, contributing to the overall functionality and reliability of the truck’s engine 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump ensures that fuel is injected at the correct timing and pressure, which is essential for efficient combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to manage the injection process. Each system has its advantages, with electronic systems generally offering more precise control and better performance 2.

Purpose and Function of the 3921148 Fuel Injection Pump

The Cummins 3921148 Fuel Injection Pump is specifically engineered to meet the demanding requirements of commercial truck engines. It operates by drawing fuel from the tank, pressurizing it, and delivering it to the engine cylinders at the precise moment required for combustion. This ensures that the engine runs smoothly and efficiently, with optimal power output and fuel economy. The pump’s ability to maintain consistent fuel pressure and timing is critical for the engine’s performance and longevity 3.

Key Features

The 3921148 Fuel Injection Pump boasts several key features that enhance its performance and reliability. Its robust design includes high-quality construction materials that withstand the rigors of heavy-duty use. The pump incorporates advanced technological aspects, such as precise metering and delivery systems, to ensure accurate fuel injection. Additionally, its durable build and efficient operation contribute to its reputation for reliability in demanding applications.

Benefits of Using the 3921148 Fuel Injection Pump

Utilizing the Cummins 3921148 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered at the optimal pressure and timing, reducing waste and enhancing combustion efficiency. This results in better engine performance, with increased power output and smoother operation. Furthermore, the precise fuel delivery helps in reducing emissions, making the engine more environmentally friendly. The pump’s reliability and durability also mean less downtime and lower maintenance costs over the vehicle’s lifespan.

Troubleshooting Common Issues

Identifying and addressing common problems with the 3921148 Fuel Injection Pump can help maintain its performance and longevity. Symptoms of issues may include rough idling, decreased power output, or irregular engine performance. Potential causes can range from clogged fuel filters to worn-out pump components. Recommended solutions include regular inspection and cleaning of the fuel system, replacing worn parts, and ensuring the pump is properly lubricated. Addressing these issues promptly can prevent more significant problems and extend the pump’s service life.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and optimal performance of the Cummins 3921148 Fuel Injection Pump. This includes routine inspections to check for wear and tear, cleaning the fuel system to prevent clogs, and replacing filters as needed. It is also important to follow the manufacturer’s guidelines for inspection intervals and replacement schedules. Proper maintenance not only enhances the pump’s efficiency but also contributes to the overall reliability of the engine.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company is committed to delivering high-performance products that meet the needs of its customers, backed by a dedication to customer satisfaction and continuous improvement. Cummins’ extensive product range and focus on technological advancement make it a trusted name in the industry.

Cummins Fuel Injection Pump 3921148 Compatibility

The Cummins Fuel Injection Pump part number 3921148 is a critical component for several diesel engines, ensuring efficient fuel delivery and combustion. This part is specifically designed to fit seamlessly with the following engines:

6C8.3 Engines

The 6C8.3 engine series benefits significantly from the precise fuel management provided by the 3921148 fuel injection pump. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The fuel injection pump ensures that the engine operates smoothly, maintaining optimal fuel efficiency and power output.

Grouping of Compatible Engines

While the 3921148 fuel injection pump is primarily associated with the 6C8.3 engine, it is also compatible with other models within the same engine family. These engines share similar design principles and operational requirements, making the 3921148 a versatile choice for multiple applications.

Other Compatible Models

In addition to the 6C8.3, the 3921148 fuel injection pump is designed to fit other Cummins engines that share similar specifications and operational needs. This compatibility ensures that users can maintain a consistent and reliable fuel delivery system across different engine models.

By using the 3921148 fuel injection pump, engine operators can expect enhanced performance, improved fuel economy, and reduced maintenance needs. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their diesel engines.

Role of Part 3921148 Fuel Injection Pump in Engine Systems

The part 3921148 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Fuel Pump

The fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump under pressure. The part 3921148 Fuel Injection Pump receives this pressurized fuel and further increases its pressure to the levels required for injection into the combustion chambers. This high-pressure fuel is then metered and timed for injection by the fuel injection pump, ensuring that the fuel is delivered at the precise moment needed for combustion.

Coordination with Injectors

Once the fuel is pressurized by the part 3921148 Fuel Injection Pump, it is sent to the fuel injectors. These injectors are responsible for spraying the fuel into the engine’s combustion chambers in a fine mist. The timing and duration of the fuel injection are controlled by the fuel injection pump, which ensures that the fuel is delivered in sync with the engine’s piston movements. This precise delivery helps in achieving better fuel atomization, leading to more efficient combustion and reduced emissions.

Integration with the Engine Control Unit (ECU)

The part 3921148 Fuel Injection Pump often communicates with the Engine Control Unit (ECU) to receive signals regarding the engine’s operational parameters such as load, speed, and temperature. Based on these inputs, the ECU sends commands to the fuel injection pump to adjust the fuel delivery accordingly. This dynamic adjustment ensures that the engine operates efficiently under varying conditions, from idle to full throttle.

Synergy with Other Ancillary Components

Other components such as fuel filters, pressure regulators, and return lines also play supporting roles in the fuel delivery system. The fuel filter ensures that any contaminants in the fuel are removed before they reach the fuel injection pump, while the pressure regulator maintains a consistent fuel pressure. The return line allows excess fuel to be sent back to the tank, maintaining a stable fuel pressure within the system.

Conclusion

In summary, the part 3921148 Fuel Injection Pump is a key player in the fuel delivery system, working in harmony with the fuel pump, injectors, ECU, and other ancillary components to ensure efficient and precise fuel delivery for optimal engine performance.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.