Introduction

The Cummins 3921135 Fuel Injection Pump is a component designed for use in commercial trucks. It is integral to the operation of diesel engines, ensuring that fuel is delivered efficiently and effectively to the engine’s combustion chambers. This pump is part of Cummins Inc.’s range of high-quality automotive parts, known for their reliability and performance in demanding applications 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at precise moments and in specific quantities. In diesel engines, the pump operates by pressurizing fuel and injecting it into the cylinders, where it mixes with air and ignites due to the high compression of the engine. The role of the fuel injection pump is vital, as it directly influences the engine’s efficiency, power output, and emissions 2.

Purpose of the Cummins 3921135 Fuel Injection Pump

The Cummins 3921135 Fuel Injection Pump plays a role in the operation of a truck by delivering fuel to the engine under high pressure. This ensures that the fuel atomizes properly within the combustion chamber, leading to efficient burning and optimal engine performance. The pump’s precise control over fuel delivery helps maintain the engine’s power and efficiency across a range of operating conditions.

Key Features

The Cummins 3921135 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in heavy-duty applications. It incorporates advanced technological features that enhance its performance, such as precise fuel metering and efficient pressure regulation. These features contribute to the pump’s ability to deliver fuel consistently and accurately.

Benefits

The Cummins 3921135 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring that fuel is delivered at the optimal pressure and timing, the pump helps the engine operate more efficiently, reducing fuel consumption. Additionally, the precise fuel delivery contributes to smoother engine operation and reduced emissions.

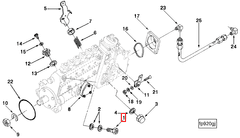

Installation Process

Installing the Cummins 3921135 Fuel Injection Pump requires careful attention to detail and the use of appropriate tools. The process involves disconnecting the old pump, cleaning the mounting area, and securing the new pump in place. It is important to follow the manufacturer’s instructions closely to ensure a proper fit and function. Precautions should be taken to avoid damaging the pump or the engine during installation.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps include leaks, inconsistent fuel delivery, and engine performance issues. Diagnosing these problems may involve checking for visible leaks, testing fuel pressure, and inspecting the pump’s electrical connections. Solutions can range from simple adjustments or repairs to replacing faulty components. Regular maintenance and inspections can help prevent many of these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3921135 Fuel Injection Pump, regular maintenance is recommended. This includes checking for leaks, ensuring proper fuel pressure, and inspecting the pump’s components for wear or damage. Following the manufacturer’s maintenance schedule and guidelines can help prevent issues and extend the life of the pump.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product range includes engines and components for on-highway, off-highway, and power generation applications, serving a wide array of industries and customers worldwide.

Cummins Fuel Injection Pump 3921135 Compatibility

The Cummins Fuel Injection Pump part number 3921135 is a critical component for several diesel engines, ensuring precise fuel delivery and optimal engine performance. This part is engineered to fit seamlessly with a range of Cummins engines, providing reliability and efficiency.

6C8.3 Engine

The 6C8.3 engine is one of the models that benefit from the 3921135 fuel injection pump. This engine is known for its robust construction and is often used in heavy-duty applications. The 3921135 pump is designed to integrate smoothly with the 6C8.3, enhancing its fuel efficiency and power output.

Grouping of Compatible Engines

The Cummins 3921135 fuel injection pump is not limited to the 6C8.3 engine alone. It is also compatible with other engines within the same family or similar specifications. These engines share common design elements and operational requirements, making the 3921135 pump a versatile choice for multiple applications.

By ensuring that the 3921135 fuel injection pump is correctly matched with its intended engine, users can expect improved performance, longevity, and reliability of their diesel engines.

Role of Part 3921135 Fuel Injection Pump in Engine Systems

The Part 3921135 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines. It works in conjunction with several key components to ensure optimal fuel delivery and combustion.

Interaction with the Fuel System

- Fuel Tank: The journey of fuel begins in the fuel tank, where it is stored until needed. The Fuel Injection Pump draws fuel from the tank via the fuel lines.

- Fuel Filter: Before reaching the Fuel Injection Pump, fuel passes through the fuel filter. This component removes impurities and contaminants, ensuring that only clean fuel enters the pump.

- Fuel Lines: These transport the filtered fuel from the tank to the Fuel Injection Pump. The integrity of these lines is essential for maintaining consistent fuel pressure and flow.

Pump Operation and Fuel Delivery

Once the fuel reaches the Fuel Injection Pump, the pump pressurizes it to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then delivered to the injectors.

Injectors and Combustion

The pressurized fuel is injected into the combustion chambers via the fuel injectors. The timing and quantity of fuel injection are precisely controlled by the Fuel Injection Pump, ensuring efficient combustion and power delivery.

Return System

Excess or unburnt fuel is returned to the fuel tank through the return lines. This closed-loop system helps maintain consistent fuel pressure and temperature within the system.

Integration with Engine Control Unit (ECU)

In modern engine systems, the Fuel Injection Pump often communicates with the Engine Control Unit (ECU). The ECU monitors various parameters such as engine load, speed, and temperature to adjust the fuel injection timing and quantity for optimal performance and emissions control.

Cooling System Interaction

The Fuel Injection Pump may also interact with the engine’s cooling system. In some designs, a small amount of coolant is used to regulate the temperature of the pump, ensuring it operates within specified temperature ranges.

Lubrication

In certain engine configurations, the Fuel Injection Pump relies on the engine’s lubrication system to keep its moving parts well-oiled. This reduces wear and tear, enhancing the longevity and reliability of the pump.

By understanding how the Part 3921135 Fuel Injection Pump fits within these engine systems, engineers and mechanics can better diagnose issues, perform maintenance, and optimize engine performance.

Conclusion

The Cummins 3921135 Fuel Injection Pump is a critical component in the efficient operation of diesel engines, particularly in commercial trucks. Its robust design, precise fuel metering, and efficient pressure regulation contribute to improved fuel efficiency, enhanced engine performance, and increased reliability. Regular maintenance and proper installation are essential to ensure the longevity and optimal performance of this Cummins part. Understanding its role within the engine system allows for better diagnostics, maintenance, and optimization of engine performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.