Introduction

The Cummins 3921106 Fuel Injection Pump is a critical component for commercial trucks, ensuring efficient operation of diesel engines. This part is integral to the fuel delivery system, supplying fuel at the correct timing and pressure for optimal engine performance and fuel efficiency 3.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers by pressurizing it and injecting it at precise moments in the engine cycle. This process enhances combustion efficiency, especially in diesel engines 1. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms, while electronic systems employ sensors and computer controls for more precise fuel management.

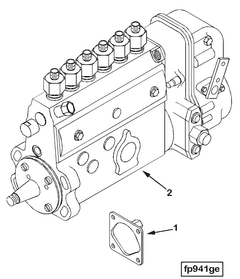

Purpose of the Cummins 3921106 Fuel Injection Pump

The Cummins 3921106 Fuel Injection Pump ensures fuel is delivered at precise timing and pressure, leading to efficient combustion. This part maintains consistent fuel delivery, which is essential for engine performance, power output, and fuel economy 3.

Key Features

This Cummins part features a robust design with high-quality materials for durability and reliability. It includes advanced technological aspects such as precise metering and high-pressure delivery capabilities. The pump is engineered to withstand the demanding conditions of commercial truck operations, ensuring consistent performance over time.

Benefits

The Cummins 3921106 Fuel Injection Pump contributes to improved fuel efficiency by delivering fuel at optimal pressure and timing, resulting in more complete combustion and enhanced engine performance. Its reliable design ensures consistent operation, reducing the likelihood of engine issues and contributing to overall vehicle reliability 3.

Installation and Integration

Installing this part requires careful consideration of compatibility with the truck’s engine system. It may necessitate modifications or adjustments for proper integration. Following the manufacturer’s guidelines for installation is crucial to avoid complications and ensure the pump functions correctly within the engine system.

Troubleshooting and Maintenance

Common issues with the Cummins 3921106 Fuel Injection Pump include leaks, inconsistent fuel delivery, or pump failure. Diagnostic tips involve checking for proper fuel pressure, inspecting for leaks, and ensuring all connections are secure. Regular maintenance practices, such as cleaning and inspecting the pump, can help prevent issues and ensure longevity and optimal performance.

Performance Enhancements

To improve engine performance, potential upgrades or modifications to the Cummins 3921106 Fuel Injection Pump may include tuning the injection timing or pressure. Accessory additions, such as performance filters or upgraded fuel lines, can also enhance the pump’s efficiency and the engine’s overall performance.

Safety Considerations

When working with the Cummins 3921106 Fuel Injection Pump, it is important to observe safety practices. This includes handling high-pressure fuel systems with care to avoid injuries from fuel spray. Ensuring that all components are properly secured and that the system is depressurized before maintenance or repairs are conducted is crucial for safety.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes engines, filtration systems, and power generation equipment, all designed to meet the demanding needs of commercial applications 2.

Role of Part 3921106 Fuel Injection Pump in Engine Systems

The 3921106 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery to the engine’s combustion chambers.

Interaction with Fuel System Components

- Fuel Tank: The fuel injection pump draws fuel from the tank, where it is stored under pressure. This ensures a consistent supply of fuel to the pump.

- Fuel Filter: Before the fuel reaches the injection pump, it passes through the fuel filter. This component removes any impurities or contaminants, ensuring that only clean fuel enters the pump.

- Fuel Lines: The fuel is transported from the tank to the pump through fuel lines. These lines must be robust and leak-free to maintain the integrity of the fuel system.

- Fuel Pressure Regulator: The injection pump works with the fuel pressure regulator to maintain the correct pressure levels. This ensures that the fuel is delivered at the optimal pressure for efficient combustion.

- Injectors: The fuel injection pump delivers pressurized fuel to the injectors. These injectors then spray the fuel into the combustion chambers in a finely atomized state, promoting better mixing with air and more complete combustion.

- Engine Control Unit (ECU): The ECU monitors various engine parameters and sends signals to the fuel injection pump to adjust the fuel delivery according to the engine’s needs. This results in improved performance and fuel efficiency.

- Sensors: Various sensors, such as the oxygen sensor and throttle position sensor, provide feedback to the ECU. This data helps the ECU make real-time adjustments to the fuel injection pump’s operation.

- Return Line: Excess fuel not used during injection is returned to the fuel tank via the return line. This helps in maintaining consistent fuel pressure within the system.

Operational Synergy

The 3921106 Fuel Injection Pump operates in a highly synchronized manner with these components. It ensures that the fuel is delivered at the right pressure and at the right time, contributing to the engine’s overall performance, efficiency, and emissions control. The pump’s ability to precisely meter fuel delivery is essential for modern engine systems that demand high precision and reliability 3.

Conclusion

The Cummins 3921106 Fuel Injection Pump is a vital component for the efficient operation of diesel engines in commercial trucks. Its precise fuel delivery ensures optimal engine performance, fuel efficiency, and reliability. Proper installation, maintenance, and understanding of its role within the engine system are crucial for maximizing its benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.