Introduction

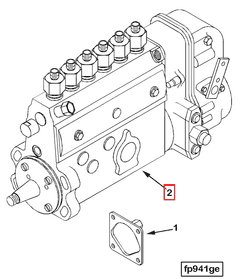

The Cummins 3921101 Fuel Injection Pump is a critical component in the operation of heavy-duty trucks. It ensures that fuel is delivered to the engine cylinders at the precise timing and pressure required for optimal performance. This pump is designed to enhance the efficiency and reliability of diesel engines, contributing to the overall functionality and longevity of the vehicle 2.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine cylinders in diesel engines. It operates by pressurizing fuel and injecting it into the combustion chamber at specific intervals, which are determined by the engine’s speed and load. The importance of fuel injection pumps in diesel engines lies in their ability to provide precise fuel delivery, which is essential for efficient combustion and engine performance 1. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to optimize fuel injection based on real-time data.

Role of the 3921101 Fuel Injection Pump in Truck Operation

The Cummins 3921101 Fuel Injection Pump is specifically designed to deliver fuel to the engine cylinders with precision. It ensures that fuel is injected at the correct timing and pressure, which is essential for maintaining engine performance and efficiency. By providing consistent and accurate fuel delivery, this pump helps to optimize combustion, reduce emissions, and enhance the overall operation of the truck 2.

Key Features of the 3921101 Fuel Injection Pump

The Cummins 3921101 Fuel Injection Pump boasts several key features that contribute to its performance and reliability. Its design incorporates high-quality materials and advanced technological aspects, such as precise metering and robust construction. These features ensure that the pump can withstand the demanding conditions of heavy-duty truck operation while maintaining optimal fuel delivery 2.

Benefits of Using the 3921101 Fuel Injection Pump

Incorporating the Cummins 3921101 Fuel Injection Pump into heavy-duty truck engines offers several benefits. These include improved fuel efficiency, enhanced engine performance, and reduced emissions. The precise fuel delivery provided by this pump ensures that the engine operates at peak efficiency, leading to better overall performance and lower environmental impact 2.

Troubleshooting Common Issues with Fuel Injection Pumps

Identifying and troubleshooting common problems associated with fuel injection pumps is important for maintaining engine performance. Symptoms of failure may include poor engine performance, increased emissions, or difficulty starting the engine. Diagnostic procedures may involve checking fuel pressure, inspecting fuel lines, and testing electrical connections. Potential solutions can range from cleaning or replacing fuel filters to repairing or replacing the pump itself 2.

Maintenance Tips for Fuel Injection Pumps

Regular maintenance of the Cummins 3921101 Fuel Injection Pump is essential for ensuring optimal performance and longevity. This includes regular inspection of fuel lines and connections, cleaning the pump and fuel system components, and replacing worn or damaged parts. Adhering to a maintenance schedule helps to prevent issues and ensures that the pump continues to operate efficiently 2.

Integration with Engine Management Systems

The Cummins 3921101 Fuel Injection Pump integrates seamlessly with modern engine management systems. This integration allows for optimized fuel delivery and engine performance by utilizing real-time data from various sensors. The pump works in conjunction with the engine control unit (ECU) to adjust fuel injection timing and pressure based on driving conditions, enhancing overall efficiency and performance 2.

Environmental Impact and Emissions Control

The Cummins 3921101 Fuel Injection Pump plays a role in meeting emissions standards and reducing the environmental impact of heavy-duty trucks. By providing precise fuel delivery, it helps to ensure complete combustion, which reduces the emission of harmful pollutants. This contributes to a lower environmental footprint and compliance with regulatory standards 2.

Cummins Corporation Overview

Cummins Inc. is a renowned manufacturer of high-quality diesel engines and components. The company has a long-standing reputation for producing reliable and efficient products, including the 3921101 Fuel Injection Pump. Cummins’ commitment to innovation and quality ensures that their products meet the demanding requirements of heavy-duty applications, providing customers with durable and performance-oriented solutions 2.

Cummins Fuel Injection Pump 3921101 Compatibility

The Cummins Fuel Injection Pump part number 3921101 is designed to fit seamlessly with a range of engine models, ensuring optimal performance and reliability. This part is engineered to deliver precise fuel metering, which is crucial for maintaining engine efficiency and power across various applications 2.

Engine Compatibility

- 6C8.3 Engines

The 3921101 fuel injection pump is specifically tailored to integrate with the 6C8.3 engine series. This compatibility ensures that the pump can handle the unique demands of this engine model, providing the necessary fuel delivery to support its operational requirements 2.

Grouping by Application

For applications that utilize multiple engine models, the 3921101 fuel injection pump offers a versatile solution. Its design allows it to be used across different engine configurations, making it a valuable component for various machinery and vehicles. This versatility is particularly beneficial for fleets and operators who need a consistent and reliable fuel delivery system across their equipment 2.

Integration and Performance

When installed in the 6C8.3 engine, the 3921101 fuel injection pump ensures that the engine receives the correct amount of fuel at the right time, enhancing overall performance. This precision in fuel delivery helps to maintain engine efficiency, reduce emissions, and extend the lifespan of the engine components. The pump’s robust construction and advanced design features contribute to its reliability and effectiveness in demanding environments 2.

Role of Part 3921101 Fuel Injection Pump in Engine Systems

In modern engine systems, the Part 3921101 Fuel Injection Pump is integral to the efficient operation of the fuel delivery system. This component works in conjunction with the Base Fuel Pump to ensure precise fuel metering and delivery to the engine’s combustion chambers 2.

The Base Fuel Pump is responsible for drawing fuel from the tank and delivering it to the Fuel Injection Pump at a consistent pressure. This initial stage of fuel delivery is vital for maintaining a steady supply of fuel, which the Fuel Injection Pump then refines 2.

Once the fuel reaches the Fuel Injection Pump, it undergoes a transformation. The pump pressurizes the fuel to a much higher level, preparing it for injection into the engine’s cylinders. This high-pressure fuel is then distributed to the injectors, which atomize the fuel into a fine mist. This mist mixes with the air in the cylinders, creating an optimal air-fuel ratio for combustion 2.

The Fuel Injection Pump’s role extends beyond mere pressurization. It also modulates the amount of fuel injected, based on signals from the engine control unit (ECU). This ensures that the engine receives the precise amount of fuel required for its current operating conditions, whether idling, cruising, or under load 2.

Conclusion

The Cummins 3921101 Fuel Injection Pump is a vital component in the operation of heavy-duty trucks, ensuring precise fuel delivery to the engine cylinders. Its integration with modern engine management systems enhances efficiency and performance, while its robust design ensures reliability in demanding environments. Regular maintenance and troubleshooting are essential for optimal performance and longevity, contributing to the overall functionality and environmental compliance of the vehicle 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.