3919111

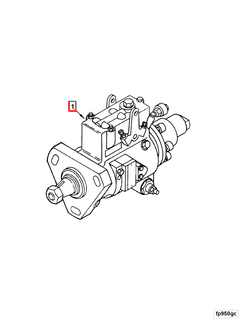

Fuel Injection Pump

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3919111 Fuel Injection Pump is a critical component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This part ensures precise fuel delivery to the engine’s combustion chambers, playing a significant role in maintaining optimal engine performance, fuel efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers pressurized fuel to the injectors in diesel engines. It operates by drawing fuel from the tank, pressurizing it, and then distributing it to the injectors at the precise moment needed for combustion. The principles of fuel injection involve delivering the right amount of fuel at the correct pressure and timing to achieve efficient combustion, which enhances engine performance, fuel economy, and reduces emissions 1.

Purpose of the Cummins 3919111 Fuel Injection Pump

The Cummins 3919111 Fuel Injection Pump is designed to deliver fuel to the engine’s combustion chambers with precision. It contributes to engine performance by ensuring that the fuel is injected at the optimal pressure and timing. This results in improved fuel efficiency, as the engine can burn fuel more completely. Additionally, precise fuel delivery helps in controlling emissions by minimizing the amount of unburned fuel that escapes into the exhaust 2.

Key Features

The Cummins 3919111 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. It incorporates advanced technological features such as electronic control for precise fuel delivery and timing. The pump’s design allows for efficient operation under a wide range of engine conditions, contributing to its effectiveness in commercial truck applications 3.

Benefits

The advantages of the Cummins 3919111 Fuel Injection Pump include improved fuel economy due to its precise fuel delivery system. Enhanced engine performance is another benefit, as the pump ensures that the engine receives the optimal amount of fuel for combustion. Additionally, the pump contributes to reduced emissions by promoting more complete fuel combustion. Its design and construction also result in increased reliability and longevity.

Troubleshooting and Maintenance

Common issues with the Cummins 3919111 Fuel Injection Pump may include fuel delivery inconsistencies or pump wear. Troubleshooting steps may involve checking fuel lines for leaks, ensuring proper pump lubrication, and verifying electronic control signals. Routine maintenance practices include regular inspection of the pump and its components, cleaning or replacing filters, and ensuring that all connections are secure. These practices help maintain optimal performance and extend the pump’s lifespan.

Integration with Engine Systems

The Cummins 3919111 Fuel Injection Pump interacts with other engine components, including fuel injectors, the engine control unit (ECU), and the exhaust system. It works in conjunction with the ECU to deliver fuel at the precise pressure and timing required for efficient combustion. The pump’s output is directed to the fuel injectors, which spray fuel into the combustion chambers. The exhaust system then manages the byproducts of combustion, including emissions.

Performance Metrics

Performance metrics associated with the Cummins 3919111 Fuel Injection Pump include fuel delivery precision, injection timing, and pressure regulation. These metrics are critical for ensuring efficient engine operation and are monitored to maintain optimal performance. The pump’s ability to deliver fuel with high precision and at the correct pressure and timing directly impacts engine efficiency and emissions.

Historical Development

The development of fuel injection technology has evolved significantly over the years, with Cummins playing a notable role in its advancement. Cummins has contributed to innovations in fuel injection systems, enhancing their efficiency, reliability, and environmental performance. The Cummins 3919111 Fuel Injection Pump is a product of this ongoing development, incorporating the latest technologies to meet the demands of modern diesel engines 4.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product portfolio and global presence underscore its leadership in the power industry.

Cummins Fuel Injection Pump 3919111 Compatibility

The Cummins Fuel Injection Pump part number 3919111 is designed to work seamlessly with various diesel engines, including the 6B5.9 engine. This part is engineered to provide precise fuel delivery, ensuring optimal engine performance and efficiency. Its design allows for compatibility across multiple engine configurations, making it a versatile choice for maintenance and repair.

When integrating this fuel injection pump into the 6B5.9 engine, it is essential to ensure that the pump’s specifications align with the engine’s requirements. This includes matching the pump’s fuel delivery rate, timing, and pressure settings to the engine’s design parameters. Proper installation and calibration are crucial to maintain the engine’s performance and longevity.

Role of Part 3919111 Fuel Injection Pump in Engine Systems

The part 3919111 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly in diesel engines where precise fuel delivery is essential for performance and emissions control. This pump works in conjunction with several key components to ensure optimal engine function.

Integration with Base Fuel Pump

The base fuel pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the Stanadyne injection pump. The part 3919111 Fuel Injection Pump then takes over, pressurizing the fuel to the levels required for injection into the engine cylinders. This pressurized fuel is essential for achieving the fine atomization needed for efficient combustion.

Coordination with Stanadyne Injection Pump

The Stanadyne injection pump is a high-pressure pump that relies on the consistent and pressurized fuel supply from the part 3919111 Fuel Injection Pump. This coordination ensures that the fuel is delivered at the precise moment and in the exact quantity needed for each combustion cycle. The Stanadyne pump’s role is to meter and inject the fuel into the cylinders, while the part 3919111 ensures the fuel is adequately pressurized beforehand.

Fuel Management

Effective fuel management is a collaborative effort between the part 3919111 Fuel Injection Pump and other fuel system components. The pump ensures a steady supply of pressurized fuel, which is vital for maintaining engine performance under varying loads and speeds. This consistent fuel pressure helps in reducing wear on injectors and other downstream components, contributing to the overall reliability of the engine system.

Pump Efficiency

The efficiency of the part 3919111 Fuel Injection Pump directly influences the performance of the entire fuel system. By maintaining optimal fuel pressure, the pump helps in achieving better fuel economy and reduced emissions. Its role in ensuring that the fuel is delivered at the right pressure and timing is fundamental to the engine’s ability to operate smoothly and efficiently.

Conclusion

The Cummins 3919111 Fuel Injection Pump is a vital component in the operation of diesel engines, ensuring precise fuel delivery and contributing to optimal engine performance, fuel efficiency, and emissions control. Its robust design, advanced features, and compatibility with various engine models make it a reliable choice for commercial truck applications. Proper maintenance and integration with other engine components are essential for maximizing its performance and longevity.

-

High Speed Off-Road Vehicles, Bruce Maclaurin, Wiley, 2018

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites, SAE International, 2013

↩ -

The History and Impact of Diesel Engines and Gas Turbines, Vaclav Smil, The MIT Press, 2010

↩ -

Operation and Maintenance Manual, X13 CM2880 X138B, Bulletin Number 5613140

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.