This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

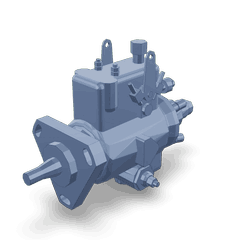

The Cummins 3919103 Fuel Injection Pump is a critical component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This pump ensures that the engine receives the precise amount of fuel needed for optimal performance and efficiency.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers. In diesel engines, this pump operates by pressurizing fuel and injecting it into the cylinders at the precise moment for combustion. There are two primary types of fuel injection pumps: mechanical and electronic. Mechanical pumps rely on engine-driven components to control fuel delivery, while electronic pumps use sensors and a control unit to manage fuel injection more precisely 1.

Purpose of the Cummins 3919103 Fuel Injection Pump

The Cummins 3919103 Fuel Injection Pump is designed to deliver precise amounts of fuel to the engine cylinders at the correct time. This ensures efficient combustion, which is essential for the engine’s performance and fuel economy. By maintaining accurate fuel delivery, the pump helps to optimize engine operation under various driving conditions 2.

Key Features

The Cummins 3919103 Fuel Injection Pump features a robust design that incorporates high-quality materials to ensure durability and reliability. It includes advanced technological elements such as precise metering systems and high-pressure capabilities, which contribute to its efficient operation. The pump’s construction allows it to withstand the demanding conditions typical of commercial truck applications 3.

Benefits

The Cummins 3919103 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. Its precise fuel delivery helps to maximize combustion efficiency, leading to better overall engine performance. Additionally, the pump’s robust construction ensures long-term reliability, reducing the need for frequent maintenance 4.

Installation and Integration

Installing the Cummins 3919103 Fuel Injection Pump requires careful attention to ensure proper integration with the truck’s fuel system. Specific requirements may vary depending on the truck model, so it is important to follow the manufacturer’s guidelines for installation. This may include aligning the pump with the engine’s fuel lines and ensuring all connections are secure 5.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3919103 Fuel Injection Pump is essential to ensure its continued reliable operation. This includes periodic inspections to check for leaks, wear, or other signs of damage. Common issues to watch for include fuel leaks, irregular engine performance, and difficulty starting the engine. Troubleshooting tips may involve checking fuel lines, inspecting the pump for damage, and ensuring all connections are tight 6.

Performance Optimization

To optimize the performance of the Cummins 3919103 Fuel Injection Pump, proper calibration is important. This may involve adjusting the pump settings to match the specific requirements of the engine and driving conditions. Additionally, using high-quality fuel and following operational best practices can help maintain the pump’s efficiency and longevity 7.

Safety Considerations

When working with the Cummins 3919103 Fuel Injection Pump, it is important to observe safety precautions. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses, and ensuring the engine is turned off before performing any maintenance or repairs. Maintenance safety protocols should be followed to prevent accidents and ensure a safe working environment 8.

Environmental Impact

The Cummins 3919103 Fuel Injection Pump contributes to more sustainable trucking operations by improving fuel efficiency and reducing emissions. Its precise fuel delivery helps to minimize unburned fuel, which can lower the overall environmental impact of diesel engines. By enhancing combustion efficiency, the pump plays a role in promoting cleaner and more efficient engine operation 9.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and components, with a strong reputation for innovation and quality. The company has a long history of developing reliable and efficient engine technologies, and its commitment to advancing diesel engine performance is evident in products like the Cummins 3919103 Fuel Injection Pump. Cummins continues to lead the industry with its focus on sustainability and technological advancement 10.

Cummins Fuel Injection Pump 3919103 Compatibility

The Cummins Fuel Injection Pump part number 3919103 is designed to be compatible with a range of engines, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of various engine applications, providing precise fuel delivery and enhancing overall engine efficiency.

Engine Compatibility

-

4B3.9 Series Engines

- The 3919103 fuel injection pump is specifically engineered to fit seamlessly with the 4B3.9 series engines. This compatibility ensures that the pump can handle the unique requirements of these engines, providing the necessary fuel pressure and timing for efficient operation.

-

Other Cummins Engines

- Beyond the 4B3.9 series, the 3919103 fuel injection pump is also compatible with a broader range of Cummins engines. This versatility makes it a valuable component for various engine models, ensuring that users can rely on consistent performance and reliability across different applications.

Installation and Performance

When installed in the appropriate engine, the Cummins 3919103 fuel injection pump delivers precise fuel metering, which is critical for maintaining engine performance and efficiency. The pump’s design allows it to work in harmony with the engine’s fuel system, ensuring smooth operation and reducing the likelihood of mechanical issues.

Reliability and Durability

Cummins is renowned for its high-quality components, and the 3919103 fuel injection pump is no exception. Built to withstand the rigors of continuous use, this pump is designed for long-term durability, ensuring that it can maintain its performance over time. This reliability is crucial for users who depend on their engines for heavy-duty applications.

Role of Part 3919103 Fuel Injection Pump in Engine Systems

The Part 3919103 Fuel Injection Pump is an essential component in the fuel delivery system of an engine, working in conjunction with several other components to ensure efficient and precise fuel delivery.

When the engine is running, the Base Fuel Pump draws fuel from the tank and delivers it to the Stanadyne Injection Pump (Part 3919103). The base fuel pump provides a consistent flow of fuel under low pressure, which is then transferred to the Stanadyne Injection Pump.

The Stanadyne Injection Pump takes this fuel and pressurizes it to a much higher level. It precisely meters the fuel into individual injectors, which then spray atomized fuel into the combustion chambers at the exact moment needed for optimal engine performance.

This high-pressure fuel delivery system ensures that the fuel is evenly distributed and atomized, leading to more complete combustion, improved fuel efficiency, and reduced emissions. The pump’s ability to deliver fuel with precision timing and pressure is what makes it a key component in modern diesel engine systems.

In summary, the interplay between the base fuel pump, the Stanadyne Injection Pump, and the overall fuel system is designed to optimize engine performance, efficiency, and emissions control.

Conclusion

The Cummins 3919103 Fuel Injection Pump is a vital component in the fuel delivery system of diesel engines, ensuring precise fuel delivery for optimal engine performance and efficiency. Its robust design, compatibility with various Cummins engines, and advanced technological features make it a reliable choice for commercial truck applications. Regular maintenance and proper installation are essential to ensure the continued reliability and performance of this part.

-

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383694.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383694.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383694.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383694.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.