3918155

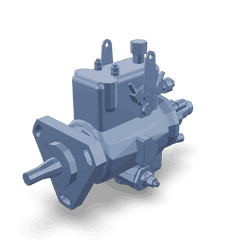

Fuel Injection Pump

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3918155 Fuel Injection Pump is designed for use in commercial trucks, facilitating the precise delivery of fuel to the engine. This pump ensures that the engine receives the correct amount of fuel at the right time, which is vital for efficient and reliable performance.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, this pump operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at high pressure. The timing and amount of fuel injected are crucial for combustion efficiency, power output, and emissions control 1.

Purpose of the Cummins 3918155 Fuel Injection Pump

The Cummins 3918155 Fuel Injection Pump delivers pressurized fuel to the engine, ensuring that fuel is injected into the combustion chambers at the precise moment required for optimal engine performance. This pump contributes to the engine’s ability to generate power efficiently and operate smoothly under various conditions 2.

Key Features

The Cummins 3918155 Fuel Injection Pump features robust construction with precision-machined components to ensure accurate fuel delivery. The use of high-quality materials contributes to its reliability and longevity. Technological advancements in this pump include improved fuel metering and injection timing, which enhance engine performance and fuel efficiency 3.

Benefits

The Cummins 3918155 Fuel Injection Pump offers improved fuel efficiency by ensuring that fuel is delivered to the engine in the most efficient manner possible. This pump also enhances engine performance by providing precise fuel injection, which is crucial for maintaining power output and responsiveness. Additionally, its reliable design ensures consistent operation, reducing the likelihood of engine-related issues.

Installation and Integration

Proper installation of the Cummins 3918155 Fuel Injection Pump is crucial for its effective operation. It should be integrated into the truck’s engine system according to the manufacturer’s guidelines. This includes ensuring that all connections are secure and the pump is properly aligned with the engine’s fuel system components. Careful attention to these details during installation will help ensure optimal performance and longevity of the pump.

Performance Optimization

To optimize the performance of the Cummins 3918155 Fuel Injection Pump, regular maintenance and tuning are recommended. This may include adjusting the injection timing and fuel delivery settings to match the specific requirements of the engine and operating conditions. Proper maintenance practices, such as cleaning and inspecting the pump components, will also contribute to its efficient operation.

Common Issues and Troubleshooting

Common issues with the Cummins 3918155 Fuel Injection Pump may include fuel delivery inconsistencies, leaks, or engine performance problems. Troubleshooting these issues involves checking the pump’s connections, inspecting for wear or damage, and ensuring that the fuel system is free of contaminants. Addressing these issues promptly can help maintain the pump’s performance and prevent more significant engine problems.

Maintenance and Care

Regular maintenance and care are essential for the longevity and efficiency of the Cummins 3918155 Fuel Injection Pump. This includes routine inspections, cleaning, and replacement of worn components. Following the manufacturer’s recommended maintenance schedule will help ensure that the pump operates at its best and contributes to the overall reliability of the truck’s engine system.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product range includes a variety of engines and components designed for commercial, industrial, and vehicle applications, demonstrating its commitment to meeting the diverse needs of its customers.

Cummins Fuel Injection Pump 3918155 Compatibility

The Cummins Fuel Injection Pump part number 3918155 is designed to work seamlessly with several engine models. This part is engineered to deliver precise fuel metering, ensuring optimal performance and efficiency across various applications.

Engine Compatibility

- 4B3.9 Engines

The 4B3.9 engines are known for their robust design and reliability, often used in heavy-duty applications. The Cummins Fuel Injection Pump 3918155 is specifically tailored to fit these engines, providing the necessary fuel delivery system to support their demanding operational requirements.

This part ensures that the 4B3.9 engines maintain consistent power output and fuel efficiency, making it an essential component for these models.

Integration and Performance

When installed in the 4B3.9 engines, the 3918155 fuel injection pump integrates smoothly with the engine’s fuel system. It is designed to handle the high-pressure demands of these engines, ensuring that fuel is delivered at the correct time and in the right amounts. This integration is crucial for maintaining engine performance and longevity.

The design of the 3918155 pump allows for precise control over fuel delivery, which is essential for the efficient operation of the 4B3.9 engines. This precision helps in reducing wear and tear on engine components, thereby extending the overall lifespan of the engine.

Reliability and Trustworthiness

Cummins is renowned for producing high-quality, reliable components, and the 3918155 fuel injection pump is no exception. This part is built to withstand the rigors of heavy-duty use, ensuring that it can perform reliably under various conditions. Its compatibility with the 4B3.9 engines underscores its robustness and effectiveness in real-world applications.

By choosing the Cummins 3918155 fuel injection pump, users can be confident in the performance and durability of their 4B3.9 engines. This part is a testament to Cummins’ commitment to providing high-quality components that meet the needs of demanding industrial and commercial applications.

Role of Part 3918155 Fuel Injection Pump in Engine Systems

The 3918155 Fuel Injection Pump is a pivotal component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery.

When the base fuel pump delivers fuel from the tank, it initially moves through a series of filters to remove impurities. The clean fuel then reaches the 3918155 Fuel Injection Pump, which is responsible for pressurizing the fuel to the required levels for injection.

This pressurized fuel is then directed to the fuel injectors, which are controlled by the engine control unit (ECU). The ECU determines the exact moment and duration for which each injector should open, based on various engine parameters such as load, speed, and temperature.

The 3918155 Fuel Injection Pump ensures that the fuel is delivered at the correct pressure and timing, which is essential for optimal combustion. This, in turn, affects the engine’s performance, fuel efficiency, and emissions.

In summary, the 3918155 Fuel Injection Pump plays a significant role in the fuel delivery process, working seamlessly with the base fuel pump, filters, fuel injectors, and the ECU to maintain engine efficiency and performance.

Conclusion

The Cummins 3918155 Fuel Injection Pump is a critical component for the efficient and reliable operation of commercial truck engines. Its precise fuel delivery, robust construction, and compatibility with various engine models make it an essential part of the fuel system. Regular maintenance and proper installation are key to ensuring its optimal performance and longevity.

-

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.