Introduction

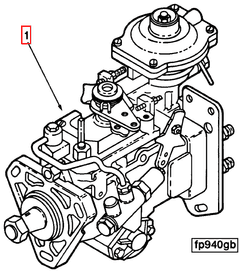

The Cummins 3917535 Fuel Injection Pump is a component designed for use in heavy-duty trucks, manufactured by Cummins Inc. Cummins is a well-established name in the automotive and heavy-duty truck industries, known for its commitment to innovation and quality in diesel engine technology. This part is integral to the efficient operation of diesel engines in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at precise moments and in exact quantities. It operates by pressurizing fuel and injecting it into the engine cylinders, where it mixes with air and ignites. In diesel engines, the fuel injection pump plays a vital role in ensuring efficient combustion, which directly impacts engine performance, fuel efficiency, and emissions. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and linkages to control fuel delivery, while electronic systems use sensors and computer controls for more precise management of the injection process 1.

Purpose of the Cummins 3917535 Fuel Injection Pump

The Cummins 3917535 Fuel Injection Pump is designed to enhance the operation of heavy-duty trucks by ensuring that fuel is delivered to the engine in a controlled and efficient manner. This pump contributes to engine performance by providing the right amount of fuel at the optimal time, which helps in achieving better fuel efficiency and reducing emissions. Its role in the truck’s engine system is to maintain a balance between fuel delivery and engine demand, ensuring smooth operation and reliable performance 4.

Key Features

The Cummins 3917535 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. It incorporates advanced technological features that enhance its performance, such as precise fuel metering and efficient pressure management. These features contribute to the pump’s ability to deliver fuel with accuracy and consistency, which is crucial for the efficient operation of diesel engines 2.

Benefits

The use of the Cummins 3917535 Fuel Injection Pump offers several advantages, including improved fuel economy, enhanced engine performance, and reduced emissions. These benefits are achieved through the pump’s precise control over fuel delivery, which ensures optimal combustion and minimizes waste. The impact of these advantages on truck operation and maintenance is significant, as they contribute to lower operating costs, extended engine life, and compliance with environmental regulations 3.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3917535 Fuel Injection Pump include leaks, inconsistent fuel delivery, and pump failure. Troubleshooting these issues involves checking for proper installation, inspecting for wear or damage, and ensuring that the pump is receiving the correct electrical signals. Routine maintenance practices, such as regular inspection, cleaning, and replacement of worn components, are recommended to ensure the optimal performance and longevity of the pump 4.

Integration with Engine Management Systems

The Cummins 3917535 Fuel Injection Pump interacts with modern engine management systems by receiving signals that dictate the timing and amount of fuel to be injected. Calibration and tuning of the pump are important for achieving desired performance outcomes, as they ensure that the pump operates in harmony with the engine’s requirements and the vehicle’s overall system.

Historical Development

The evolution of fuel injection technology has seen significant advancements, with Cummins playing a notable role in its development. The company has contributed to the field through innovations that have improved the efficiency, reliability, and environmental performance of diesel engines. These advancements have led to the development of the 3917535 Fuel Injection Pump, which represents the culmination of years of research and engineering.

Environmental Impact

Advanced fuel injection systems, such as the Cummins 3917535, contribute to lower emissions and improved air quality by ensuring more complete and efficient combustion of fuel. These systems play a role in reducing the environmental footprint of heavy-duty trucks by minimizing the release of pollutants and greenhouse gases.

Cummins Company Overview

Cummins Inc. was founded with a vision to innovate in the diesel engine industry. Over the years, the company has grown to become a leader in the automotive and heavy-duty truck sectors, known for its commitment to quality and innovation in manufacturing. Cummins’ dedication to advancing diesel technology has positioned it as a key player in the industry, with a strong focus on developing products that meet the evolving needs of its customers and the demands of environmental regulations.

Cummins Fuel Injection Pump 3917535 Compatibility

The Cummins Fuel Injection Pump part number 3917535 is designed to integrate seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of diesel engines, providing precise fuel delivery that enhances engine efficiency and power output.

Engine Compatibility

-

4B3.9 Series: The 3917535 fuel injection pump is specifically tailored for the 4B3.9 engine series. This engine is known for its robust construction and is widely used in various industrial and commercial applications. The pump’s design ensures it can handle the high pressures and demands of this engine, providing consistent fuel flow and contributing to the engine’s overall performance.

-

Group Compatibility: The 3917535 fuel injection pump is also compatible with other engines within the same family as the 4B3.9. This includes engines that share similar architecture and operational requirements. By ensuring compatibility across a range of engines, this part offers flexibility and ease of use for maintenance and repair purposes.

Integration and Performance

The integration of the 3917535 fuel injection pump with the 4B3.9 engine and similar models is straightforward, thanks to its standardized design and fit. This pump is engineered to interface perfectly with the engine’s fuel system, ensuring that it can deliver fuel with the precision needed for optimal combustion. The result is improved engine performance, reduced emissions, and enhanced durability.

Reliability and Durability

Cummins is renowned for producing high-quality, durable components, and the 3917535 fuel injection pump is no exception. Built to withstand the rigors of continuous operation, this pump is designed to provide long-lasting performance. Its robust construction ensures it can handle the high pressures and temperatures associated with diesel engines, making it a reliable choice for both maintenance and replacement needs.

Maintenance and Service

Maintaining the 3917535 fuel injection pump is essential for ensuring the longevity and efficiency of the 4B3.9 engine and similar models. Regular inspections and timely replacements of worn components can prevent potential issues and keep the engine running smoothly. Cummins provides comprehensive service support and resources to assist with the maintenance and repair of this critical component.

Role of Part 3917535 Fuel Injection Pump in Engine Systems

The Part 3917535 Fuel Injection Pump, specifically designed as a Bosch Injection Pump, is integral to the efficient operation of diesel engine systems. This pump is responsible for delivering fuel to the engine’s combustion chambers at precise timing and pressure, ensuring optimal performance and fuel efficiency.

Integration with Engine Components

-

Fuel Tank and Lines: The pump draws diesel fuel from the tank through the fuel lines. It is essential that the lines are free from obstructions and leaks to maintain consistent fuel delivery.

-

Fuel Filter: Before reaching the pump, fuel passes through a filter that removes impurities. A clean fuel supply is vital for the pump’s longevity and performance.

-

Governor: The governor regulates the amount of fuel delivered by the pump based on engine load and speed. It works in conjunction with the pump to maintain the desired engine performance.

-

Injectors: The high-pressure fuel from the pump is delivered to the injectors, which atomize the fuel into the combustion chambers. Proper synchronization between the pump and injectors is necessary for efficient combustion.

-

Timing Mechanism: The pump must be accurately timed with the engine’s crankshaft to ensure fuel is injected at the correct point in the engine cycle. This timing is typically adjusted using a timing gear or chain connected to the crankshaft.

-

Return System: Excess fuel not injected into the cylinders is returned to the tank via the return lines. This system helps in maintaining the desired fuel pressure and temperature.

-

Sensors and Control Units: Modern engines may incorporate sensors that provide feedback to the engine control unit (ECU) about fuel delivery. The ECU can then adjust the pump’s operation for optimal performance and emissions control.

In summary, the Part 3917535 Fuel Injection Pump is a key component that interacts with various parts of the engine system to ensure precise fuel delivery, which is fundamental for the engine’s operation, efficiency, and emissions standards.

Conclusion

The Cummins 3917535 Fuel Injection Pump is a critical component in the operation of heavy-duty diesel engines, offering enhanced performance, fuel efficiency, and reduced emissions. Its integration with engine management systems and compatibility with various engine models make it a versatile and reliable choice for heavy-duty applications. Regular maintenance and proper troubleshooting are essential to ensure the longevity and optimal performance of this part.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.