3917391

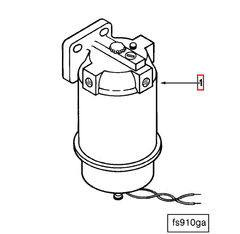

Fuel Water Separator

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3917391 Fuel Water Separator is a component designed to enhance the efficiency and reliability of heavy-duty trucks. Its role is to remove water and contaminants from the fuel before it reaches the engine, thereby supporting optimal engine performance and longevity.

Basic Concepts of Fuel Water Separators

A Fuel Water Separator is a device that filters out water and other impurities from diesel fuel. It operates by allowing fuel to pass through a filter medium that captures water and contaminants, ensuring that only clean fuel enters the engine. This process is vital for diesel engines, as water and impurities can cause corrosion, reduce fuel efficiency, and lead to engine damage over time 1.

Purpose of the Cummins 3917391 Fuel Water Separator

The Cummins 3917391 Fuel Water Separator functions by intercepting the fuel supply and filtering out water and contaminants. This ensures that the fuel delivered to the engine is clean, which helps maintain engine efficiency, reduces wear on engine components, and prevents potential damage caused by water in the fuel system.

Key Features

The Cummins 3917391 Fuel Water Separator is characterized by its robust design and the use of high-quality materials. It incorporates advanced filtration technology to effectively remove water and contaminants from the fuel. The separator is engineered to be durable and reliable, ensuring long-term performance in demanding conditions.

Benefits of Using the Cummins 3917391 Fuel Water Separator

Incorporating the Cummins 3917391 Fuel Water Separator into a truck’s fuel system offers several advantages. It contributes to improved engine performance by ensuring that the fuel delivered to the engine is free from contaminants. This can lead to better fuel efficiency and reduced emissions. Additionally, by preventing water and impurities from entering the engine, the separator helps extend the engine’s lifespan and reduces the likelihood of costly repairs 2.

Installation Process

Installing the Cummins 3917391 Fuel Water Separator involves several steps. First, the existing fuel filter should be removed. The separator is then installed in its place, ensuring all connections are secure. It may be necessary to use specific tools for a proper installation, and following the manufacturer’s instructions is recommended to ensure correct setup.

Regular Maintenance Practices

To ensure the Cummins 3917391 Fuel Water Separator operates effectively, regular maintenance is required. This includes draining accumulated water from the separator at recommended intervals and replacing the filter element as needed. Adhering to these maintenance practices helps maintain the separator’s efficiency and prolongs its service life.

Troubleshooting Common Issues

Common issues with the Cummins 3917391 Fuel Water Separator may include water accumulation beyond normal levels, reduced fuel flow, or filter clogging. Addressing these issues may involve draining the accumulated water, checking for proper installation, or replacing the filter element. Regular inspections and maintenance can help identify and resolve these issues promptly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry, known for its commitment to quality, innovation, and customer satisfaction 3.

Role of Part 3917391 Fuel Water Separator in Engine Systems

In the orchestration of engine systems, the 3917391 Fuel Water Separator assumes a significant role by ensuring the purity of fuel delivered to the engine. This component is strategically positioned within the fuel system to intercept and remove water and other contaminants from the fuel before it reaches the engine’s combustion chamber.

Integration with Fuel System Components

The Fuel Water Separator works in tandem with the fuel filter to enhance the overall efficiency and reliability of the fuel system. As fuel flows from the tank through the system, it first encounters the fuel filter, which removes larger particulates. The separator then takes over, targeting water and finer impurities that could otherwise bypass the filter.

Contribution to Engine Performance

By ensuring that only clean, dry fuel enters the engine, the separator helps maintain optimal combustion efficiency. This is particularly important for high-performance engines where fuel quality directly impacts power output and emissions. The separator’s role is to prevent water-induced corrosion within the fuel system and to avoid the detrimental effects of water in the fuel, such as reduced efficiency and potential engine damage.

Interaction with Engine Accessories

Engine accessories that rely on a consistent and clean fuel supply, such as fuel injectors and pumps, benefit from the presence of the Fuel Water Separator. It ensures that these components operate within their designed parameters, thereby extending their service life and maintaining engine performance standards.

Overall System Harmony

The seamless integration of the Fuel Water Separator within the fuel system contributes to the overall harmony of engine operation. It acts as a safeguard against the incursion of water and contaminants, allowing other components to function optimally without the risk of premature wear or failure. This component is a testament to the intricate balance required within engine systems to achieve peak performance and durability.

Conclusion

The Cummins 3917391 Fuel Water Separator plays a vital role in maintaining the efficiency and reliability of heavy-duty truck engines by ensuring that the fuel delivered to the engine is free from water and contaminants. Its integration into the fuel system enhances engine performance, extends engine lifespan, and reduces the likelihood of costly repairs. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Gas Turbine Engineering Handbook 4th Edition, Meherwan P Boyce, Butterworth-Heinemann, 2011.

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.