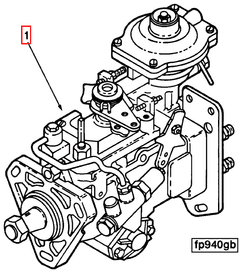

The Cummins 3916994 Fuel Injection Pump is a critical component designed for use in commercial truck engines, manufactured by Cummins Inc. This pump ensures that fuel is delivered to the engine cylinders with precision in terms of timing and pressure, which is essential for the efficient operation of diesel engines 1. Cummins, a well-established name in the engine manufacturing industry, is renowned for its commitment to quality and innovation, making this Cummins part a reliable choice for heavy-duty applications 2.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the cylinders at specific intervals, which are determined by the engine’s operational needs 3. In diesel engines, the fuel injection pump plays a vital role by ensuring that fuel is delivered at high pressure, which is necessary for the fuel to atomize properly and combust efficiently. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and electronic control units (ECUs) to manage fuel injection with greater precision and adaptability to varying engine conditions 4.

Purpose of the Cummins 3916994 Fuel Injection Pump

The Cummins 3916994 Fuel Injection Pump is designed to deliver fuel to the engine cylinders at precise timing and pressure. This ensures optimal combustion, which is critical for the engine’s performance and efficiency. By maintaining consistent fuel delivery, the pump contributes to the engine’s power output, fuel economy, and emissions control. Its role is fundamental in the operation of diesel engines, particularly in commercial trucks where reliability and performance are paramount 5.

Key Features

The Cummins 3916994 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and performance. It incorporates advanced technological features such as precise metering and injection timing control, which are crucial for efficient engine operation. The pump’s design also allows for easy maintenance and serviceability, ensuring that it can be readily inspected and repaired when necessary 6.

Benefits

The Cummins 3916994 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring that fuel is delivered at the correct pressure and timing, the pump helps to optimize combustion, which can lead to better fuel economy and reduced emissions. Additionally, its robust construction and advanced features contribute to the overall reliability and longevity of the engine 7.

Common Issues and Troubleshooting

Fuel injection pumps, including the Cummins 3916994, can encounter issues such as leaks, clogged filters, or worn-out components, which may affect engine performance. Common causes of these problems include contamination of the fuel, lack of maintenance, or normal wear and tear. Troubleshooting steps may involve inspecting the pump for leaks, cleaning or replacing filters, and checking for worn components. Regular maintenance and inspections are important to identify potential issues early and ensure the pump operates efficiently 8.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3916994 Fuel Injection Pump, regular maintenance is recommended. This includes checking for leaks, ensuring that fuel filters are clean and functioning properly, and following the manufacturer’s service intervals for inspections and replacements of wear-prone components. Additionally, using high-quality fuel and keeping the fuel system clean can help prevent issues and extend the life of the pump 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a leader in the commercial truck industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product line and technological advancements have made it a preferred choice for engine components, including fuel injection pumps, in the heavy-duty truck market 10.

Cummins Fuel Injection Pump 3916994 Compatibility

The Cummins Fuel Injection Pump part number 3916994 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of Cummins engines, providing precise fuel delivery and efficient combustion.

Engine Compatibility

6B5.9 Engines

The 3916994 Fuel Injection Pump is specifically engineered to integrate with the 6B5.9 engine series. This engine is known for its robust performance and is widely used in various industrial and commercial applications. The compatibility ensures that the pump can handle the specific fuel requirements and operational demands of the 6B5.9 engine, maintaining its efficiency and longevity.

Other Cummins Engines

While the primary focus is on the 6B5.9 engine, the 3916994 Fuel Injection Pump is also designed to fit other Cummins engines within the same series or similar specifications. This versatility allows for broader application across different models, ensuring that the pump can be used interchangeably where needed. The design and engineering of this part are tailored to provide a reliable fit and function across various Cummins engine models, enhancing overall engine performance.

Role of Part 3916994 Fuel Injection Pump in Engine Systems

The part 3916994 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Integration with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The part 3916994 Fuel Injection Pump receives this pre-pressurized fuel and further increases its pressure to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then distributed to the fuel injectors, which atomize the fuel for combustion.

Coordination with Fuel Injectors

Fuel injectors are the final stage in the fuel delivery process. They receive the high-pressure fuel from the part 3916994 Fuel Injection Pump and spray it into the combustion chambers in a finely atomized state. This ensures that the fuel mixes thoroughly with the air, leading to more complete and efficient combustion.

Interaction with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in regulating the operation of the part 3916994 Fuel Injection Pump. It monitors various engine parameters such as load, speed, and temperature, and adjusts the fuel injection timing and quantity accordingly. This real-time control ensures that the engine operates within its optimal efficiency and emissions standards.

Role in the Common Rail System

In engines equipped with a common rail fuel system, the part 3916994 Fuel Injection Pump is responsible for maintaining a constant high-pressure fuel reservoir. This allows for more precise control over the injection process, as the ECU can command the injectors to open and close at specific times, regardless of engine speed or load conditions.

Contribution to Overall Engine Performance

The efficient operation of the part 3916994 Fuel Injection Pump directly influences several key engine performance metrics. It ensures that the correct amount of fuel is delivered at the right time, which enhances fuel efficiency, reduces emissions, and improves overall engine responsiveness. Additionally, precise fuel delivery contributes to smoother engine operation and reduced wear on engine components.

Conclusion

The Cummins 3916994 Fuel Injection Pump is a vital component in the fuel delivery system of diesel engines, particularly in commercial truck applications. Its robust design, precise metering, and integration with other engine components ensure optimal engine performance, fuel efficiency, and reliability. Regular maintenance and adherence to manufacturer guidelines are essential to maximize the longevity and efficiency of this part.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 6312702.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.