Introduction

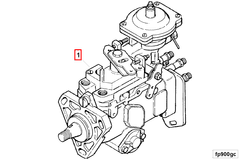

The Cummins 3916990 Fuel Injection Pump is a critical component in the operation of commercial trucks, especially those equipped with Cummins diesel engines. This part ensures that the engine receives the precise amount of fuel needed for optimal performance. Its design and functionality are tailored to meet the demanding requirements of heavy-duty applications, contributing to the overall efficiency and reliability of the vehicle 2.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are integral to the operation of diesel engines. They work by pressurizing fuel and delivering it to the engine cylinders at the precise moment required for combustion. The pump’s operation is based on the principles of hydraulics and mechanical engineering, utilizing a cam-driven mechanism to control fuel delivery. The importance of fuel injection pumps in diesel engines lies in their ability to provide accurate fuel metering, which is essential for engine performance, fuel efficiency, and emissions control 1.

Purpose of the Cummins 3916990 Fuel Injection Pump

The Cummins 3916990 Fuel Injection Pump is designed to deliver fuel to the engine cylinders in a controlled and precise manner. It ensures that the fuel is injected at the correct pressure and timing, which is essential for efficient combustion. This part contributes to the overall performance of the truck by contributing to smooth engine operation, reduced fuel consumption, and lower emissions 2.

Key Features

The Cummins 3916990 Fuel Injection Pump boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring durability in harsh operating conditions. Technological advancements such as electronic control and precise fuel metering systems are integrated into the pump, allowing for improved efficiency and performance. Additionally, the pump’s construction is engineered to withstand the high pressures and temperatures associated with diesel fuel injection 3.

Benefits of Using the Cummins 3916990 Fuel Injection Pump

Utilizing the Cummins 3916990 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in the most effective manner possible. This results in better overall engine performance and reduced operating costs. Furthermore, the pump’s precise fuel metering helps in reducing emissions, making it compliant with environmental regulations. The reliability and durability of the pump also mean less frequent maintenance and longer service intervals 2.

Troubleshooting and Maintenance Suggestions

To maintain optimal performance and longevity of the Cummins 3916990 Fuel Injection Pump, regular maintenance is recommended. This includes checking for leaks, ensuring proper fuel filtration, and monitoring the pump’s operation for any signs of wear or malfunction. Common issues such as erratic engine performance or difficulty starting can often be traced back to the fuel injection pump. Diagnostic procedures may involve checking the pump’s pressure output and inspecting the mechanical components for wear 1.

Integration with Engine Management Systems

The Cummins 3916990 Fuel Injection Pump is designed to work seamlessly with modern engine management systems. It interacts with electronic control units (ECUs) and sensor feedback loops to adjust fuel delivery in real-time based on engine load, speed, and other operating conditions. This integration allows for precise control over fuel injection, enhancing engine performance and efficiency while meeting emissions standards 3.

Historical Development and Technological Advancements

The evolution of fuel injection pump technology has seen significant milestones and innovations. Early mechanical pumps have given way to more advanced electronic and common rail systems. The Cummins 3916990 represents a culmination of these advancements, incorporating electronic control and precise metering technologies that have been refined over years of research and development 2.

Environmental Impact and Emissions Control

The Cummins 3916990 Fuel Injection Pump plays a role in meeting emissions regulations and reducing the environmental impact of diesel engines. By ensuring precise fuel delivery and efficient combustion, it helps in minimizing the release of harmful pollutants. This contributes to cleaner air and compliance with stringent environmental standards 1.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history of innovation and quality, Cummins has established itself as a trusted name in the diesel engine and component manufacturing industry. The company’s commitment to advancing technology and sustainability is evident in its product portfolio, which includes high-performance engines, filtration systems, and aftermarket parts 2.

Cummins Fuel Injection Pump 3916990 Compatibility

The Cummins Fuel Injection Pump part number 3916990 is designed to integrate seamlessly with various engine models, ensuring optimal performance and reliability. This fuel injection pump is engineered to meet the specific needs of the following engines:

6B5.9 Engine Series

The 6B5.9 engine series benefits significantly from the 3916990 fuel injection pump. This engine model is known for its robust design and efficiency, making it a popular choice in various applications. The 3916990 pump ensures precise fuel delivery, enhancing the engine’s power output and fuel economy.

Grouping by Application

The 3916990 fuel injection pump is also compatible with other engine models within the same application group. These engines share similar operational characteristics and performance requirements, making the 3916990 pump a versatile choice for multiple engine types.

Performance and Reliability

The integration of the 3916990 fuel injection pump with the specified engines is designed to provide consistent performance and reliability. This compatibility ensures that the pump meets the stringent demands of the engine, contributing to overall system efficiency and longevity.

Role of Part 3916990 Fuel Injection Pump in Engine Systems

The part 3916990 Fuel Injection Pump is integral to the efficient operation of engine systems, particularly when paired with Bosch injection systems. This pump is responsible for delivering fuel at precise pressures and timings, which are essential for optimal combustion within the engine cylinders.

When integrated with the Bosch injection pump, the 3916990 ensures that fuel is atomized into fine particles before entering the combustion chamber. This atomization is vital for thorough mixing with air, leading to more complete combustion and enhanced engine performance.

The pump works in conjunction with the fuel injectors, which are tasked with spraying the atomized fuel into the cylinders. The timing and pressure of the fuel delivery are controlled by the 3916990, ensuring that the injectors operate within their specified parameters.

Additionally, the 3916990 Fuel Injection Pump interfaces with the engine’s electronic control unit (ECU). The ECU monitors various engine parameters and adjusts the fuel delivery accordingly, optimizing fuel efficiency and reducing emissions.

Conclusion

In summary, the 3916990 Fuel Injection Pump plays a significant role in the fuel delivery system of engine components, ensuring that fuel is delivered at the right pressure and timing for efficient combustion. Its integration with Bosch injection systems enhances engine performance, fuel efficiency, and emission control 3.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.