Introduction

The Cummins 3915979 Fuel Injection Pump is a component designed for use in heavy-duty trucks. It plays a role in the operation of these vehicles by ensuring that fuel is delivered to the engine in a controlled and efficient manner. This part is integral to the performance and reliability of the truck’s engine, contributing to its overall efficiency and power output.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers at the precise moment and pressure required for optimal performance. In diesel engines, the fuel injection pump plays a role by atomizing the fuel into fine particles, which then mix with the air in the combustion chamber to facilitate efficient combustion. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and computer controls to manage the injection process, offering greater precision and adaptability 1.

Purpose of the Cummins 3915979 Fuel Injection Pump

The Cummins 3915979 Fuel Injection Pump is designed to deliver fuel to the engine at the exact timing and pressure needed for efficient combustion. This precise delivery ensures that the engine operates smoothly and efficiently, maximizing power output while minimizing fuel consumption. The pump’s role is vital in maintaining the engine’s performance under various operating conditions.

Key Features

The Cummins 3915979 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability. It incorporates advanced technological features such as precise fuel metering and high-pressure delivery capabilities. These features contribute to the pump’s efficiency and effectiveness in supporting the engine’s performance 2.

Benefits

The use of the Cummins 3915979 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring that fuel is delivered at the optimal timing and pressure, the pump helps to maximize the engine’s efficiency and power output. Additionally, its robust construction and advanced features contribute to its longevity and reliability, making it a valuable component for heavy-duty truck engines 3.

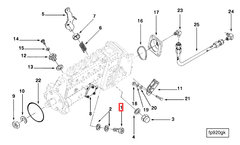

Installation and Integration

Proper installation and integration of the Cummins 3915979 Fuel Injection Pump into a truck’s engine system are crucial for ensuring optimal performance. This process involves careful alignment and connection of the pump to the engine’s fuel system, following manufacturer guidelines to ensure compatibility and efficiency. It is important to consider any prerequisites or specific considerations related to the truck’s engine model to facilitate a smooth integration.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are key to ensuring the longevity and optimal performance of the Cummins 3915979 Fuel Injection Pump. Common issues may include fuel delivery inconsistencies or pump wear, which can be addressed through routine inspections and servicing. Signs of wear or failure, such as decreased engine performance or unusual noises, should be monitored to prevent further damage and ensure safe operation.

Performance and Efficiency

The Cummins 3915979 Fuel Injection Pump significantly contributes to the overall performance and efficiency of the truck. By delivering fuel at the precise timing and pressure, it enhances fuel economy and power output, ensuring that the engine operates at its best. This efficient fuel delivery is crucial for maintaining the truck’s performance under various load and speed conditions.

Safety Considerations

When working with the Cummins 3915979 Fuel Injection Pump, it is important to observe safety considerations to ensure safe handling and maintenance. This includes following proper procedures for installation, maintenance, and troubleshooting, as well as being aware of potential hazards associated with fuel systems. Adhering to safety guidelines helps to protect both the equipment and the individuals involved in its maintenance.

Cummins Company Overview

Cummins Inc. is a renowned manufacturer with a strong reputation in the industry for producing high-quality diesel engines and components. The company is committed to innovation and quality, continuously advancing its product offerings to meet the evolving needs of its customers. Cummins’ dedication to excellence is evident in its wide range of reliable and efficient engine components, including the Cummins 3915979 Fuel Injection Pump.

Compatibility

The Cummins Fuel Injection Pump part number 3915979 is designed to ensure precise fuel delivery, which is essential for maintaining engine performance and efficiency. This part is compatible with several engine models, including the 6C8.3, ensuring optimal fuel injection timing and pressure. Additionally, the 3915979 is part of a broader group of engines where it provides similar functionality, ensuring that it can be used across multiple models with similar fuel injection requirements.

Role in Engine Systems

The Cummins 3915979 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The 3915979 receives this fuel and further pressurizes it to the levels required for injection into the combustion chambers. This pressurized fuel is then delivered through fuel lines to the injectors, which atomize the fuel into a fine mist for combustion.

Fuel Lines and Filters

Fuel lines transport the pressurized fuel from the injection pump to the injectors. The 3915979 ensures that the fuel is delivered at consistent pressure, which is vital for the injectors to function correctly. Fuel filters, positioned along the fuel lines, remove impurities from the fuel before it reaches the injection pump, ensuring that only clean fuel is pressurized and injected.

Injectors

The injectors are the final destination for the pressurized fuel. The 3915979 Fuel Injection Pump’s role is to provide the necessary pressure for the injectors to atomize the fuel effectively. Proper atomization ensures a more complete combustion process, which enhances engine efficiency and reduces emissions.

Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors and controls the operation of the fuel injection pump. Sensors provide the ECU with data on engine load, speed, and other parameters. The ECU then sends signals to the 3915979 to adjust the fuel pressure and delivery rate accordingly, ensuring that the engine receives the precise amount of fuel needed for any given condition.

Return System

Excess fuel that is not injected into the combustion chambers is returned to the fuel tank via a return line. The 3915979 Fuel Injection Pump manages this return flow, ensuring that the system maintains the correct pressure levels. This return system helps in dissipating heat and keeping the fuel cool, which is important for maintaining fuel quality and engine performance.

Conclusion

In summary, the Cummins 3915979 Fuel Injection Pump plays a significant role in the fuel delivery system by ensuring that fuel is pressurized and delivered efficiently to the injectors, working in harmony with the base fuel pump, fuel lines, filters, injectors, ECU, and the return system. Its robust design, advanced features, and compatibility with various engine models make it a valuable component for maintaining engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.