Introduction

The Cummins 3915168 Fuel Injection Pump is a component designed for use in commercial truck engines, manufactured by Cummins Inc. Cummins is a well-established name in the commercial vehicle industry, known for producing reliable and high-performance diesel engines and components. This part is part of Cummins’ extensive lineup of parts that contribute to the efficiency and performance of diesel engines in heavy-duty applications.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the combustion chambers of a diesel engine. It operates by pressurizing fuel and injecting it into the engine at precise timing and pressure, which is important for efficient combustion. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, whereas electronic systems use sensors and electronic control units (ECUs) to manage fuel injection more precisely, offering better performance and emissions control 1.

Purpose of the Cummins 3915168 Fuel Injection Pump

The Cummins 3915168 Fuel Injection Pump plays a role in the operation of a truck by ensuring that fuel is delivered to the engine’s combustion chambers at the correct timing and pressure. This precise delivery is vital for optimal engine performance, efficiency, and emissions control. The pump’s function is to pressurize fuel and inject it into the engine, facilitating the combustion process that powers the vehicle 2.

Key Features

The Cummins 3915168 Fuel Injection Pump is characterized by its robust design and the use of high-quality materials, ensuring durability and reliability in demanding commercial applications. It incorporates advanced technological features that enhance its performance, such as precise fuel metering and efficient pressure regulation. These features contribute to the pump’s ability to deliver fuel with accuracy and consistency 3.

Benefits

The use of the Cummins 3915168 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. By ensuring precise fuel delivery, the pump helps to optimize combustion, leading to better fuel economy and reduced emissions. Its reliable operation contributes to the overall durability and performance of the engine 4.

Troubleshooting and Maintenance

Common issues with the Cummins 3915168 Fuel Injection Pump may include symptoms such as poor engine performance, difficulty starting, or irregular idling. Diagnosing these issues often involves checking for proper fuel pressure, inspecting for leaks, and ensuring the pump’s components are in good condition. Regular maintenance, such as cleaning or replacing filters and inspecting for wear, can help ensure the longevity and optimal performance of the pump 5.

Integration with Engine Management Systems

The Cummins 3915168 Fuel Injection Pump integrates with modern engine management systems, including electronic control units (ECUs) and sensors, to optimize engine performance and emissions. This integration allows for precise control over fuel injection timing and pressure, enhancing the engine’s efficiency and reducing its environmental impact 6.

Environmental Impact

The use of advanced fuel injection technology, such as the Cummins 3915168, contributes to reduced emissions and improved fuel economy. By ensuring precise fuel delivery and efficient combustion, these systems help minimize the environmental footprint of diesel engines, aligning with global efforts to reduce emissions and promote sustainable transportation solutions 7.

Historical Development

The development of fuel injection technology has seen significant milestones and innovations over the years. From the early mechanical systems to the advanced electronic systems of today, each innovation has contributed to improved engine performance, efficiency, and emissions control. The Cummins 3915168 Fuel Injection Pump is a product of this evolutionary process, incorporating the latest advancements in fuel injection technology 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a leader in the commercial vehicle industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications 9.

Cummins Fuel Injection Pump 3915168 Compatibility

The Cummins Fuel Injection Pump part number 3915168 is designed to integrate seamlessly with a range of engine models, ensuring optimal performance and reliability. This part is specifically engineered to meet the stringent demands of various engine configurations, providing precise fuel delivery essential for efficient engine operation.

Grouped Engine Compatibility

- 6C8.3 Engines

- The 3915168 Fuel Injection Pump is a perfect fit for the 6C8.3 engines. This compatibility ensures that the pump delivers the necessary fuel pressure and timing, important for maintaining the engine’s power and efficiency.

Specific Engine Models

- 6C8.3

- The 3915168 part number is tailored for the 6C8.3 engine, ensuring that it aligns with the engine’s design specifications. This alignment is important for achieving the desired performance metrics and longevity of the engine.

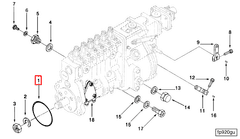

Installation and Integration

The installation of the Cummins Fuel Injection Pump 3915168 is straightforward, designed to fit into the engine’s existing architecture without requiring significant modifications. This ease of integration is a testament to Cummins’ commitment to providing high-quality, user-friendly components. The pump’s design ensures that it works in harmony with the engine’s fuel system, contributing to smooth operation and reduced maintenance needs 10.

Role of Part 3915168 Fuel Injection Pump in Engine Systems

The part 3915168 Fuel Injection Pump is integral to the efficient operation of modern engine systems. It works in concert with several key components to ensure optimal fuel delivery and engine performance.

Integration with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The part 3915168 Fuel Injection Pump receives this pressurized fuel and further increases its pressure to the levels required for injection into the engine cylinders. This high-pressure fuel is then metered and injected precisely into the combustion chamber, ensuring efficient fuel atomization and combustion 11.

Interaction with Fuel Injectors

Once the fuel is pressurized by the part 3915168 Fuel Injection Pump, it is distributed to the fuel injectors. These injectors are responsible for spraying the fuel into the engine cylinders in a finely atomized state. The precise timing and amount of fuel injected are controlled by the engine’s electronic control unit (ECU), which communicates with the fuel injection pump to maintain optimal performance under varying load and speed conditions 12.

Coordination with the Engine Control Unit (ECU)

The ECU plays a significant role in the operation of the part 3915168 Fuel Injection Pump. It monitors various engine parameters such as engine speed, load, temperature, and air intake. Based on this data, the ECU sends signals to the fuel injection pump to adjust the fuel delivery rate and pressure. This ensures that the engine operates efficiently across a wide range of conditions, from idle to full throttle 13.

Synergy with the Common Rail System

In engines equipped with a common rail fuel system, the part 3915168 Fuel Injection Pump is particularly important. It pressurizes the fuel to a very high level and stores it in a common rail. From there, the fuel is distributed to each injector as needed. This system allows for more precise control over the injection timing and quantity, leading to improved fuel efficiency and reduced emissions 14.

Contribution to Turbocharging Systems

In turbocharged engines, the part 3915168 Fuel Injection Pump must deliver fuel at even higher pressures to match the increased air density provided by the turbocharger. This ensures that the fuel-air mixture remains optimal, allowing the engine to produce more power without compromising efficiency or emissions 15.

Role in Aftertreatment Systems

The precise fuel delivery provided by the part 3915168 Fuel Injection Pump also plays a role in the effectiveness of aftertreatment systems, such as diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems. By ensuring that the fuel is burned efficiently, these systems can operate more effectively, reducing the overall emissions output of the engine 16.

Conclusion

In summary, the part 3915168 Fuel Injection Pump is a key component in the fuel delivery system of modern engines, working in harmony with various other components to ensure efficient, powerful, and clean operation.

-

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Wang, Yushu. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). X15 CM2350 X132C, Service Manual (5504572).

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Wang, Yushu. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). X15 CM2350 X132C, Service Manual (5504572).

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). X15 CM2350 X132C, Service Manual (5504572).

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩ -

Wang, Yushu. (2007). Introduction to Engine Valvetrains. SAE International.

↩ -

Cummins Inc. (n.d.). X15 CM2350 X132C, Service Manual (5504572).

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Hilgers, Michael. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.