Introduction

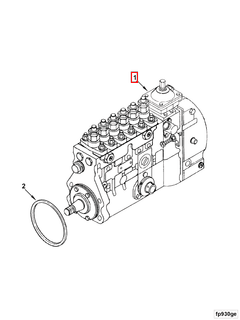

The Cummins 3914490 Fuel Injection Pump is a critical component for commercial trucks, designed to enhance diesel engine performance and efficiency by delivering fuel at the correct timing and pressure 4.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps deliver fuel to the engine’s combustion chambers by pressurizing it and injecting it at precise moments in the engine cycle. This process is essential for efficient combustion in diesel engines 1. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems use physical components and cam-driven mechanisms, while electronic systems employ sensors and computer controls for greater precision and efficiency 2.

Purpose of the Cummins 3914490 Fuel Injection Pump

This Cummins part ensures optimal combustion by delivering fuel at precise timing and pressure, contributing to the engine’s performance, efficiency, and reduced emissions 4.

Key Features

The 3914490 is characterized by its robust design and high-quality materials. It features precision-machined components, durable seals, and a robust housing capable of withstanding high pressures and temperatures. The design also facilitates easy maintenance and service 4.

Benefits

This part offers improved fuel efficiency, enhanced engine performance, and reduced emissions by ensuring optimal fuel delivery and complete combustion 4.

Installation and Integration

Proper installation of this part is essential for optimal performance. It should be integrated according to the manufacturer’s guidelines, ensuring compatibility with the specific engine model 3.

Troubleshooting and Maintenance

Common issues may include leaks, inconsistent fuel delivery, or pump failure. Troubleshooting involves checking connections, inspecting for wear or damage, and ensuring correct electrical signals. Regular maintenance, such as cleaning and replacing worn components, ensures longevity and optimal performance 4.

Performance and Efficiency

The 3914490 plays a significant role in the truck’s performance and efficiency by ensuring precise fuel delivery, contributing to better fuel economy and increased power output 4.

Safety Considerations

When working with this part, it is important to observe safety practices, including handling fuel with care, performing maintenance with the engine off and the fuel system depressurized, and wearing proper personal protective equipment 4.

Cummins Corporation

Cummins Inc. is a reputable manufacturer known for its high-quality engines and components, focusing on efficiency, durability, and environmental responsibility 4.

Role of Part 3914490 Fuel Injection Pump in Engine Systems

Integration with the Base Fuel Pump

The base fuel pump draws fuel from the tank and delivers it to the 3914490, which pressurizes it to the required levels for injection into the engine’s combustion chambers 4.

Interaction with Fuel Injectors

The 3914490 ensures that fuel is delivered at the correct pressure and timing, allowing fuel injectors to atomize the fuel effectively for a more complete and efficient burn 4.

Coordination with Engine Control Unit (ECU)

The ECU manages the fuel injection process by receiving data from sensors and sending signals to the 3914490 to adjust fuel delivery, ensuring optimal engine operation under varying conditions 4.

Support from Fuel Filters

Fuel filters remove impurities and contaminants, ensuring the 3914490 operates smoothly and efficiently, preventing wear and potential damage 4.

Contribution to Overall Engine Efficiency

The 3914490 contributes to engine efficiency by ensuring precise fuel delivery, enhancing combustion efficiency, reducing emissions, and improving fuel economy 4.

Conclusion

The Cummins 3914490 Fuel Injection Pump is a vital component for commercial trucks, ensuring optimal engine performance, efficiency, and reduced emissions through precise fuel delivery. Its robust design, advanced features, and integration with other engine components make it a valuable asset for commercial vehicle operators.

-

Matthew Harrison, Controlling Noise and Vibration in Road Vehicles, SAE International, 2004.

↩ -

Konrad Reif, Automotive Mechatronics, Springer Vieweg, 2015.

↩ -

QSK60 CM2350 K121, Bulletin Number 4388646, Operation and Maintenance Manual.

↩ -

Qianfan Xin, Diesel Engine System Design, Woodhead Publishing Limited, 2011.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.