Introduction

The Cummins 3914299 Fuel Injection Pump is a critical component in the fuel delivery system of heavy-duty trucks. It ensures precise fuel delivery to the engine, which is essential for optimal performance, efficiency, and emissions control. This part is engineered to meet the demanding requirements of heavy-duty applications, providing reliable and consistent fuel supply under various operating conditions.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is responsible for delivering fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this component plays a significant role in ensuring efficient combustion and overall engine performance. Fuel injection systems can be mechanical or electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 3914299 Fuel Injection Pump

The Cummins 3914299 Fuel Injection Pump is integral to the operation of a truck’s engine. It ensures that fuel is delivered at the right pressure and timing, which contributes to engine performance, fuel efficiency, and emissions control. By providing consistent and accurate fuel delivery, this pump helps maintain engine power, reduce fuel consumption, and minimize harmful emissions 2.

Key Features

The Cummins 3914299 Fuel Injection Pump is characterized by its robust design and high-quality construction materials. It incorporates advanced technological features that enhance its performance and reliability. These features include precision-machined components, durable materials resistant to wear and corrosion, and innovative designs that improve fuel delivery efficiency. The pump’s construction ensures it can withstand the rigors of heavy-duty use while maintaining optimal performance 3.

Benefits

The Cummins 3914299 Fuel Injection Pump offers several advantages. It contributes to improved fuel economy by ensuring efficient fuel delivery, which reduces overall fuel consumption. The pump also enhances engine power by providing consistent and precise fuel injection, leading to better performance. Additionally, it helps reduce emissions by ensuring clean and efficient combustion. The pump’s durable construction increases its longevity, providing reliable operation over extended periods 4.

Installation and Integration

Proper installation of the Cummins 3914299 Fuel Injection Pump is crucial for optimal performance. It should be integrated into the truck’s engine system following manufacturer guidelines to ensure compatibility and correct setup. This involves careful alignment, secure mounting, and proper connection to the fuel lines and engine components. Correct installation ensures that the pump operates efficiently and contributes to the overall performance of the engine.

Troubleshooting Common Issues

Common issues with fuel injection pumps can include symptoms such as poor engine performance, difficulty starting, or irregular idling. Troubleshooting steps may involve inspecting the pump for signs of wear or damage, checking fuel lines for leaks, and ensuring proper installation. Diagnostic procedures can help identify specific problems, such as clogged fuel filters or malfunctioning components, allowing for effective repairs or replacements.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and efficient operation of the Cummins 3914299 Fuel Injection Pump. This includes periodic inspections for signs of wear or damage, cleaning fuel lines and filters to prevent clogs, and replacing wear parts as needed. Adhering to recommended maintenance intervals and procedures helps maintain the pump’s performance and reliability, reducing the risk of unexpected failures.

Performance Enhancements

Optional upgrades or modifications can be made to the Cummins 3914299 Fuel Injection Pump to further improve engine performance. These may include performance-tuned components, upgraded fuel filters, or enhanced sealing solutions. Such enhancements can provide benefits such as increased fuel efficiency, higher engine power, and improved overall performance. However, it is important to consider the compatibility and potential impact of these modifications on the engine system.

Cummins Corporation Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative and high-quality products. The company has a long history of producing reliable and efficient fuel injection systems, including the Cummins 3914299 Fuel Injection Pump. Cummins is committed to advancing technology and maintaining high standards in manufacturing, ensuring that their products meet the needs of heavy-duty applications and contribute to the performance and efficiency of diesel engines.

Cummins Fuel Injection Pump 3914299 Compatibility

The Cummins Fuel Injection Pump part number 3914299 is designed to be compatible with a range of engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of various applications, providing precise fuel delivery essential for the efficient operation of the engines.

Engine Compatibility

6C8.3 Engines

The Cummins Fuel Injection Pump 3914299 is specifically engineered to fit seamlessly with the 6C8.3 engines. This compatibility ensures that the pump can handle the unique requirements of these engines, delivering the necessary fuel pressure and timing for peak performance. The 6C8.3 engines benefit from this pump’s precision, which helps in maintaining consistent power output and fuel efficiency.

Grouped Engine Models

In addition to the 6C8.3 engines, the 3914299 fuel injection pump is also compatible with other Cummins engine models that share similar design and operational characteristics. These engines rely on the pump’s ability to provide accurate fuel metering, which is crucial for maintaining engine health and performance. The pump’s design allows it to integrate smoothly with these engines, ensuring that they operate at their best.

By ensuring compatibility with these engines, the Cummins Fuel Injection Pump 3914299 helps maintain the reliability and efficiency of the engines it supports. This compatibility is a testament to Cummins’ commitment to providing high-quality components that meet the needs of various engine applications.

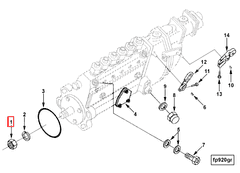

Role of Part 3914299 Fuel Injection Pump in Engine Systems

The Part 3914299 Fuel Injection Pump is integral to the efficient operation of engine systems, working in concert with several key components to ensure optimal performance.

Interaction with the Base Fuel Pump

The Base Fuel Pump serves as the initial stage in the fuel delivery process, drawing fuel from the tank and delivering it to the fuel injection pump. The Part 3914299 Fuel Injection Pump then takes over, pressurizing the fuel to the precise levels required for injection into the engine cylinders. This pressurized fuel is essential for achieving the fine mist necessary for efficient combustion.

Coordination with Fuel Injectors

Once pressurized by the fuel injection pump, the fuel is delivered to the Fuel Injectors. These injectors spray the fuel into the combustion chamber in a highly atomized state, ensuring thorough mixing with air for complete combustion. The fuel injection pump’s role here is to maintain consistent pressure, which directly influences the injectors’ performance and the engine’s overall efficiency.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various parameters such as engine speed, load, and temperature to adjust the fuel delivery. It sends signals to the fuel injection pump to modulate the fuel pressure and flow rate accordingly. This dynamic interaction ensures that the engine operates within optimal parameters under varying conditions.

Contribution to the Common Rail System

In engines equipped with a Common Rail Fuel System, the fuel injection pump plays a pivotal role in maintaining the high-pressure fuel reservoir. It ensures that the fuel is always available at the required pressure for the injectors to operate effectively, enhancing both performance and fuel economy.

Support for Turbocharging

In turbocharged engines, the fuel injection pump must deliver fuel at even higher pressures to match the increased air density provided by the turbocharger. This ensures that the fuel-air mixture remains optimal, preventing issues such as knocking and ensuring smooth power delivery.

Enhancement of Emission Control

Modern engines are equipped with Emission Control Systems that rely on precise fuel delivery to minimize pollutants. The fuel injection pump’s ability to deliver fuel with high precision directly contributes to these systems’ effectiveness, helping the engine meet stringent emission standards.

Conclusion

The Cummins 3914299 Fuel Injection Pump is a key component that interacts with various engine systems to ensure efficient, reliable, and clean operation. Its role in pressurizing and delivering fuel is fundamental to the performance and efficiency of the engine.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.