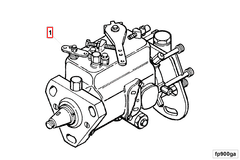

The Cummins 3914210 Fuel Injection Pump is a component designed for use in heavy-duty trucks. Manufactured by Cummins Inc., a well-established name in the diesel engine industry, this fuel injection pump is integral to the efficient operation of diesel engines in heavy-duty applications. Its role is to deliver precise amounts of fuel to the engine cylinders at the correct pressure and timing, ensuring optimal performance and efficiency 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device used in diesel engines to deliver fuel to the combustion chamber. Unlike carburetors, which mix air and fuel before it enters the engine, fuel injection pumps deliver fuel directly into the combustion chamber. This direct delivery allows for more precise control over the fuel-air mixture, leading to better combustion efficiency and reduced emissions 2. This Cummins part operates on this principle, providing a reliable and efficient means of fuel delivery for heavy-duty truck engines.

Purpose of the Cummins 3914210 Fuel Injection Pump

This Cummins part plays a role in the operation of a truck by delivering fuel to the engine cylinders. It ensures that the fuel is delivered at the correct pressure and timing, which is crucial for the efficient combustion process. This precise fuel delivery helps maintain engine performance, fuel efficiency, and emissions standards 3.

Key Features

The Cummins 3914210 Fuel Injection Pump is characterized by several key features. Its design incorporates high-quality materials to ensure durability and reliability in demanding heavy-duty applications. The pump features advanced technological aspects, such as precise fuel metering and high-pressure delivery capabilities, which contribute to its efficient operation. Additionally, its construction allows for easy maintenance and repair, enhancing its practicality for fleet operations.

Benefits

This Cummins part offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the engine in a controlled and precise manner. This efficient fuel delivery also enhances engine performance, allowing for better power output and smoother operation. Furthermore, the pump’s reliable design and construction contribute to its durability, reducing the likelihood of failures and the need for frequent repairs.

Operation and Functionality

The Cummins 3914210 Fuel Injection Pump operates by using engine-driven mechanical energy to pressurize fuel and deliver it to the engine cylinders. The pump’s internal components, including the plunger and cam, work together to meter and deliver fuel at the precise moment and pressure required for combustion. This process ensures that the fuel is atomized properly within the combustion chamber, leading to efficient burning and reduced emissions.

Installation Process

Installing the Cummins 3914210 Fuel Injection Pump involves several steps. First, ensure that the engine is clean and free of debris. Then, using the appropriate tools, remove the old pump and install the new one in its place. It is important to follow the manufacturer’s instructions carefully to ensure proper installation. This may include torquing bolts to the specified settings and ensuring all connections are secure.

Maintenance and Troubleshooting

Maintaining the Cummins 3914210 Fuel Injection Pump is crucial for its longevity and performance. Regular inspections and cleanings can prevent buildup and ensure smooth operation. Common issues that may arise include leaks, irregular fuel delivery, and pump noise. Troubleshooting these issues often involves checking for worn components, ensuring proper installation, and verifying that all connections are secure. Regular maintenance can help identify potential problems before they become serious.

Performance Impact

The Cummins 3914210 Fuel Injection Pump has a noticeable impact on the overall performance of the truck. By ensuring precise fuel delivery, it contributes to improved fuel economy and engine power. This efficient fuel management allows the engine to operate more smoothly and with greater efficiency, which can lead to reduced operating costs and enhanced vehicle performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the diesel engine industry. The company’s commitment to advancing diesel technology has led to the development of products like the Cummins 3914210 Fuel Injection Pump, which embodies their dedication to efficiency, reliability, and performance in heavy-duty applications.

Cummins Fuel Injection Pump 3914210 Compatibility

The Cummins Fuel Injection Pump part number 3914210 is designed to fit seamlessly with a variety of engine models, ensuring optimal performance and reliability. This part is engineered to meet the specific needs of the engines it supports, providing precise fuel delivery and enhancing overall engine efficiency.

Engine Compatibility

-

6B5.9 Series

- The 3914210 fuel injection pump is specifically tailored for the 6B5.9 engines, ensuring that it integrates smoothly with the engine’s architecture. This compatibility is crucial for maintaining the engine’s performance and longevity.

-

Other Cummins Engines

- While the primary focus is on the 6B5.9 series, the 3914210 fuel injection pump may also be compatible with other Cummins engines within the same family or similar specifications. This versatility allows for broader application across various engine models, providing a reliable solution for multiple engine types.

Integration and Performance

The integration of the 3914210 fuel injection pump with the 6B5.9 engines is designed to enhance the engine’s fuel delivery system. This ensures that the engine operates at peak efficiency, with precise control over fuel injection timing and quantity. The pump’s design allows for seamless interaction with the engine’s components, contributing to improved performance and reduced wear and tear.

Reliability and Durability

Cummins is renowned for its high-quality components, and the 3914210 fuel injection pump is no exception. Built to withstand the rigors of heavy-duty use, this pump is designed for durability and long-term reliability. Its robust construction ensures that it can handle the demands of various operating conditions, providing consistent performance over time.

Installation and Maintenance

Installing the 3914210 fuel injection pump is a straightforward process, thanks to its compatibility with the 6B5.9 engines. Proper installation is crucial for ensuring that the pump functions correctly and integrates seamlessly with the engine. Regular maintenance of the pump is also essential to maintain its performance and longevity. Cummins provides detailed guidelines for maintenance, ensuring that users can keep their engines running smoothly.

Role of Part 3914210 Fuel Injection Pump in Engine Systems

The part 3914210 Fuel Injection Pump is integral to the efficient operation of engine systems by ensuring precise fuel delivery. This pump works in conjunction with several key components to maintain optimal engine performance.

Integration with the Fuel System

-

Fuel Tank: The pump draws fuel from the tank, where it is stored under pressure. This ensures a consistent supply of fuel to the engine.

-

Fuel Filter: Before reaching the pump, fuel passes through a filter that removes impurities. This clean fuel is then delivered to the pump for pressurization.

-

Fuel Lines: Pressurized fuel from the pump is transported through fuel lines to the injectors. These lines must be robust to withstand the high pressure generated by the pump.

Interaction with Engine Components

-

Fuel Injectors: The pump delivers high-pressure fuel to the injectors, which spray atomized fuel into the combustion chamber. This precise delivery ensures efficient combustion.

-

Engine Control Unit (ECU): The ECU monitors various engine parameters and adjusts the pump’s output to maintain optimal fuel delivery. This interaction ensures that the engine operates within specified performance and emission standards.

-

Combustion Chamber: The atomized fuel mixes with air in the combustion chamber, where it is ignited. The pump’s role in delivering the right amount of fuel at the right pressure is essential for complete combustion and engine efficiency.

Supporting Components

-

Pressure Regulator: This component works with the pump to maintain consistent fuel pressure, ensuring stable engine operation under varying conditions.

-

Return Line: Excess fuel not used by the injectors is returned to the tank via a return line. This system helps in maintaining the desired fuel pressure and temperature.

By understanding how the part 3914210 Fuel Injection Pump interacts with these components, engineers and mechanics can better diagnose issues and ensure the engine system operates efficiently.

Conclusion

The Cummins 3914210 Fuel Injection Pump is a critical component in the efficient operation of heavy-duty diesel engines. Its precise fuel delivery system ensures optimal engine performance, fuel efficiency, and emissions control. With its robust design and compatibility with various engine models, this Cummins part is a reliable solution for fleet operations, contributing to reduced operating costs and enhanced vehicle performance.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.