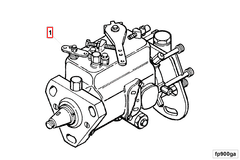

The Cummins 3914182 Fuel Injection Pump is a vital component in the operation of commercial trucks. This pump is designed to deliver precise amounts of fuel to the engine, ensuring optimal performance, fuel efficiency, and emissions control. Its role in the diesel engine system is significant, contributing to the overall efficiency and reliability of the vehicle 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that delivers fuel to the engine’s combustion chambers. It operates by pressurizing fuel and injecting it into the engine at precise moments to optimize combustion. In diesel engines, the fuel injection pump plays a role in ensuring that the fuel is delivered at the right pressure and timing. There are two primary types of fuel injection systems: mechanical and electronic. Mechanical systems rely on physical components and cam-driven mechanisms to control fuel delivery, while electronic systems use sensors and computer controls to manage the injection process. Each system has its advantages, with electronic systems generally offering more precise control and better performance 2.

Role of the 3914182 Fuel Injection Pump in Truck Operation

The Cummins 3914182 Fuel Injection Pump is specifically designed to enhance the operation of commercial trucks. It ensures that fuel is delivered to the engine in a controlled and efficient manner, which directly impacts engine performance. By providing the correct amount of fuel at the right time, the pump helps to maintain consistent power output and smooth operation. Additionally, it contributes to fuel efficiency by ensuring that fuel is used effectively, reducing waste and improving overall economy. The pump also plays a role in emissions control by promoting complete and efficient combustion, which helps to minimize harmful emissions 3.

Key Features of the 3914182 Fuel Injection Pump

The Cummins 3914182 Fuel Injection Pump is characterized by several key features that set it apart from other models. Its design incorporates advanced technology to ensure precise fuel delivery. The construction of the pump is robust, built to withstand the demanding conditions of commercial truck operation. Unique attributes of the pump include its ability to adapt to varying engine loads and speeds, ensuring optimal performance under all driving conditions. Additionally, the pump is engineered for durability, providing long-lasting reliability in heavy-duty applications.

Benefits of Using the 3914182 Fuel Injection Pump

Using the Cummins 3914182 Fuel Injection Pump offers several benefits. One of the primary advantages is improved fuel efficiency, as the pump ensures that fuel is used effectively, reducing consumption and operating costs. Enhanced engine performance is another benefit, with the pump contributing to smoother operation and consistent power delivery. Additionally, the pump helps to reduce emissions by promoting efficient combustion, which is increasingly important in meeting environmental regulations. The reliability and durability of the pump also contribute to lower maintenance costs and extended service life.

Troubleshooting and Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 3914182 Fuel Injection Pump, regular maintenance and troubleshooting are important. Common issues with fuel injection pumps can include leaks, inconsistent fuel delivery, and pump wear. Regular inspections and maintenance checks can help identify and address these issues early. It is also important to follow the manufacturer’s recommended maintenance schedule, which may include filter changes, pump adjustments, and system checks. Keeping the fuel system clean and free of contaminants is important for the pump’s performance. Additionally, using high-quality fuel and filters can help prevent issues and ensure the pump operates efficiently.

Cummins Corporation Overview

Cummins Corporation, founded in 1919, has a long-standing reputation in the automotive industry for innovation, quality, and customer satisfaction. The company has grown to become a global leader in the design, manufacture, and distribution of diesel and natural gas engines, as well as related technologies. Cummins is committed to advancing engine technology and providing reliable, high-performance solutions for a variety of applications. The company’s dedication to innovation is evident in its continuous development of new products and technologies that enhance engine efficiency, performance, and environmental sustainability. Cummins’ focus on quality and customer satisfaction ensures that its products, including the 3914182 Fuel Injection Pump, meet the highest standards of reliability and performance.

Cummins Fuel Injection Pump 3914182 Compatibility

The Cummins Fuel Injection Pump part number 3914182 is designed to fit seamlessly with various engine models, ensuring optimal performance and reliability. This part is engineered to meet the stringent demands of modern diesel engines, providing precise fuel delivery and efficient combustion.

Engine Compatibility

- 6B5.9 Series

- The 3914182 fuel injection pump is specifically engineered to integrate with the 6B5.9 engine series. This compatibility ensures that the pump can handle the unique requirements of the 6B5.9 engines, including their power output and operational demands.

Performance and Reliability

The Cummins 3914182 fuel injection pump is built to deliver consistent fuel flow, which is crucial for maintaining engine performance and efficiency. Its design allows for precise control over fuel delivery, which is essential for achieving optimal combustion and reducing emissions.

Installation and Integration

When installing the 3914182 fuel injection pump, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes checking for any necessary modifications or adjustments that may be required for specific engine configurations. Proper installation is key to maximizing the performance and longevity of both the pump and the engine.

Maintenance and Support

Regular maintenance of the Cummins 3914182 fuel injection pump is essential to ensure continued performance. This includes routine inspections and servicing as recommended by Cummins. Utilizing genuine Cummins parts and following recommended maintenance schedules will help in maintaining the pump’s efficiency and reliability.

By understanding the compatibility and integration of the Cummins 3914182 fuel injection pump with various engine models, users can ensure that their engines operate at peak performance levels.

Role of Part 3914182 Fuel Injection Pump in Engine Systems

The part 3914182 Fuel Injection Pump is an integral component in the fuel delivery system of an engine, working in conjunction with several other components to ensure optimal engine performance.

Interaction with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. The part 3914182 Fuel Injection Pump receives this pre-pressurized fuel and further increases its pressure to the levels required for injection into the combustion chambers. This high-pressure fuel is then distributed to the fuel injectors, which atomize the fuel for efficient combustion.

Coordination with Fuel Injectors

Fuel injectors are the final point in the fuel delivery system where pressurized fuel is sprayed into the engine’s cylinders. The part 3914182 Fuel Injection Pump ensures that the fuel injectors receive a consistent and precise amount of high-pressure fuel, allowing for accurate fuel metering and efficient combustion. This precision is vital for maintaining engine performance, fuel efficiency, and emissions control.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) monitors various engine parameters and adjusts the fuel injection timing and quantity accordingly. The part 3914182 Fuel Injection Pump works in harmony with the ECU to deliver the exact amount of fuel needed under varying engine loads and conditions. Sensors provide real-time data to the ECU, which then sends signals to the fuel injection pump to make necessary adjustments.

Role in the Common Rail System

In engines equipped with a common rail fuel system, the part 3914182 Fuel Injection Pump plays a key role in maintaining the high-pressure fuel rail. The pump pressurizes the fuel and stores it in the common rail, from which the fuel injectors draw as needed. This system allows for more precise control over fuel delivery and enhances overall engine efficiency and performance.

Contribution to Emission Control Systems

Modern engines are equipped with various emission control systems, such as Exhaust Gas Recirculation (EGR) and Selective Catalytic Reduction (SCR). The part 3914182 Fuel Injection Pump ensures that the fuel is delivered in a manner that complements these systems, helping to reduce harmful emissions and comply with environmental regulations.

Support for Turbocharging

In turbocharged engines, the part 3914182 Fuel Injection Pump must deliver fuel at even higher pressures to match the increased air density provided by the turbocharger. This ensures that the fuel-air mixture remains optimal, allowing the engine to produce more power without compromising efficiency or reliability.

Conclusion

In summary, the part 3914182 Fuel Injection Pump is a vital component that interacts with multiple systems within the engine to ensure efficient and precise fuel delivery, ultimately contributing to the engine’s overall performance, efficiency, and compliance with emission standards.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.