Introduction

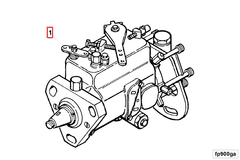

The Cummins 3912865 Fuel Injection Pump is a component designed for use in heavy-duty trucks. It ensures the precise delivery of fuel to the engine cylinders, contributing to both power output and fuel economy. This part is integral to the efficient and reliable performance of diesel engines 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump pressurizes diesel fuel and delivers it to the engine cylinders in a controlled manner. It uses mechanical or electronic means to create high-pressure fuel that is then injected into the combustion chamber at the optimal time for efficient burning. This system is essential for the fuel delivery process in diesel engines, ensuring that fuel is delivered at the correct pressure and timing to maximize engine performance and efficiency 2.

Purpose of the Cummins 3912865 Fuel Injection Pump

This Cummins part is designed to deliver fuel to the engine cylinders with precision. It controls the timing and pressure of fuel injection, ensuring that the fuel is atomized properly within the combustion chamber, leading to efficient combustion and optimal engine performance 3.

Key Features

The Cummins 3912865 Fuel Injection Pump incorporates advanced technology to enhance performance and reliability. It is constructed using durable materials to withstand the harsh conditions of heavy-duty truck operation. Precise engineering ensures accurate fuel delivery, contributing to the overall efficiency and power of the engine 4.

Benefits

This part contributes to improved fuel efficiency by ensuring that fuel is delivered at the optimal pressure and timing. This results in more complete combustion and reduced fuel consumption. Additionally, the pump enhances engine performance by providing consistent and precise fuel delivery, which is crucial for maintaining engine power and responsiveness. Its reliable design also contributes to the longevity and dependability of the engine 1.

Installation and Integration

Proper installation of the Cummins 3912865 Fuel Injection Pump is important for ensuring its effective operation. Installation procedures should follow manufacturer guidelines to ensure that the pump is correctly positioned and securely mounted. This may involve preparing the engine compartment, aligning the pump with the fuel system components, and ensuring all connections are tight and secure. Careful attention to these details during installation helps to prevent issues such as leaks or improper fuel delivery 3.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3912865 Fuel Injection Pump is important for ensuring its continued optimal performance. This includes periodic inspections to check for signs of wear or damage, cleaning the pump and its components to remove any buildup that could affect performance, and addressing any issues promptly to prevent further complications. Common troubleshooting tips for this pump may involve checking for leaks, ensuring proper fuel pressure, and verifying the timing of fuel delivery to diagnose and resolve any operational issues 4.

Common Issues and Solutions

Several common issues may arise with the Cummins 3912865 Fuel Injection Pump, including leaks, irregular fuel delivery, and decreased performance. Solutions to these problems may involve inspecting and tightening connections, cleaning or replacing components as necessary, and ensuring that the pump is operating within its specified parameters. Preventive measures, such as regular maintenance and careful operation, can help to minimize the occurrence of these issues 2.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines and related components, with a reputation for innovation and quality in the industry. The company has a long history of developing reliable and efficient engine technologies, and its commitment to advancing diesel engine performance is evident in products like the Cummins 3912865 Fuel Injection Pump. Cummins’ focus on research and development ensures that its components meet the demanding requirements of heavy-duty applications, providing customers with durable and high-performing solutions for their vehicles 1.

Cummins Fuel Injection Pump 3912865 Compatibility

The Cummins Fuel Injection Pump part number 3912865 is designed to fit seamlessly with the following engines:

- 6B5.9 Series: The 6B5.9 engine series benefits from the 3912865 fuel injection pump, which is engineered to provide the necessary fuel pressure and timing for efficient combustion. This compatibility ensures that the engine operates smoothly and maintains its power output 1.

Role of Part 3912865 Fuel Injection Pump in Engine Systems

This part is an integral component in the fuel delivery system of an engine, working in concert with several other components to ensure optimal engine performance.

Interaction with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. This part receives this fuel and further pressurizes it to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then distributed to individual injectors, which atomize the fuel for efficient combustion 2.

Coordination with Fuel Injectors

Fuel injectors rely on the pressurized fuel supplied by this part to deliver precise amounts of fuel into each cylinder. The injection timing and quantity are controlled by the engine’s electronic control unit (ECU), which communicates with the fuel injection pump to maintain the desired air-fuel ratio for combustion 3.

Integration with the Engine Control Unit (ECU)

The ECU plays a significant role in the operation of this part. It monitors various engine parameters such as engine speed, load, and temperature. Based on this data, the ECU sends signals to the fuel injection pump to adjust the fuel pressure and flow rate, ensuring that the engine operates efficiently under varying conditions 4.

Synergy with Sensors

Various sensors, including the mass airflow sensor, oxygen sensor, and throttle position sensor, provide real-time data to the ECU. This information allows the ECU to make precise adjustments to the fuel injection pump’s operation, optimizing fuel delivery for both performance and emissions control 2.

Collaboration with the Fuel Rail

The fuel rail acts as a distribution manifold for the pressurized fuel from this part. It ensures that each fuel injector receives a consistent supply of high-pressure fuel, which is essential for uniform fuel distribution across all cylinders 3.

Interaction with the Fuel Filter

The fuel filter works in tandem with this part by removing impurities from the fuel before it reaches the injection pump. Clean fuel is vital for the proper operation of the fuel injection pump and injectors, preventing wear and ensuring precise fuel metering 4.

Conclusion

In summary, the Cummins 3912865 Fuel Injection Pump is a key player in the fuel delivery system, interacting with multiple components to ensure that the engine receives the right amount of fuel at the right pressure for optimal performance. Its advanced design, precise engineering, and reliable operation make it a critical component for heavy-duty diesel engines.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ ↩ ↩ ↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ ↩ ↩ ↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ ↩ ↩ ↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.