Introduction

The Cummins 3912860 Fuel Injection Pump is integral to the operation of heavy-duty trucks, ensuring the engine receives the precise amount of fuel for optimal performance, efficiency, and emissions control.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump delivers fuel to the engine’s combustion chambers at the correct pressure and timing. In diesel engines, this pump pressurizes fuel and injects it into the combustion chamber at precise moments during the engine cycle, which is essential for efficient combustion and engine performance. Fuel injection systems can be mechanical or electronic, with mechanical systems relying on physical components and cam-driven mechanisms, and electronic systems using sensors and computer controls for more precise fuel management 1.

Purpose of the Cummins 3912860 Fuel Injection Pump

This Cummins part is designed to deliver fuel to the engine under high pressure, ensuring efficient combustion and optimal engine performance. It enhances fuel efficiency through precise fuel delivery and aids in emissions control by ensuring clean and efficient combustion 2.

Key Features

The Cummins 3912860 Fuel Injection Pump features a robust design constructed from high-quality materials for durability and reliability. It incorporates advanced technological features such as precision engineering for accurate fuel delivery and enhanced sealing mechanisms to prevent leaks, contributing to the pump’s overall performance and longevity 3.

Benefits

Using this part offers several benefits, including improved fuel economy due to precise fuel delivery, enhanced engine performance through optimal combustion, reduced emissions thanks to efficient fuel use, and increased reliability from its durable construction and advanced features.

Installation and Integration

Proper installation of the Cummins 3912860 Fuel Injection Pump involves ensuring compatibility with the truck’s engine system and making necessary adjustments for optimal performance. It is important to follow manufacturer guidelines to integrate the pump effectively, ensuring it operates within the specified parameters for the best results 4.

Maintenance and Service

Routine maintenance and service procedures are essential for the longevity and optimal performance of this Cummins part. Regular inspections, following recommended service intervals, and addressing any issues promptly can help maintain the pump’s efficiency and reliability. An inspection checklist should include checking for leaks, ensuring proper fuel pressure, and verifying the pump’s alignment and connections.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps can include fuel leaks, inconsistent fuel delivery, and engine performance issues. Troubleshooting methods involve identifying symptoms such as rough idling or decreased power, using diagnostic techniques to pinpoint the issue, and performing repair or replacement procedures as necessary. Regular maintenance can help prevent many of these issues.

Performance Enhancements

Potential upgrades or modifications to the Cummins 3912860 Fuel Injection Pump can enhance engine performance. These may include performance tuning to optimize fuel delivery, using higher-quality fuel filters to ensure clean fuel, and other modifications that can improve the pump’s efficiency and the engine’s overall performance.

Environmental Impact

This part plays a role in reducing emissions by ensuring efficient fuel combustion. This contributes to more sustainable trucking operations by minimizing the environmental impact of heavy-duty trucks. Efficient fuel use and reduced emissions are key factors in promoting environmentally friendly transportation solutions.

Cummins Corporation

Cummins Inc. is a leading manufacturer of diesel engines and related technologies, with a strong commitment to innovation and quality. The company offers a wide range of products designed to meet the needs of various industries, including heavy-duty trucking. Cummins’ dedication to advancing diesel engine technology ensures that their products, like the 3912860 Fuel Injection Pump, deliver reliable performance and efficiency.

Compatibility

The Cummins Fuel Injection Pump part number 3912860 is designed to work seamlessly with various Cummins engine models. This part is engineered to ensure precise fuel delivery, which is essential for optimal engine performance and efficiency. Below is a detailed look at the engines with which this fuel injection pump is compatible.

Compatible Engines

- 4B3.9

- 6BT5.9

- QSB6.7

- QSC6.7

Engine Grouping

The Cummins Fuel Injection Pump 3912860 is particularly suited for engines within the following groups:

- 4B Series: This includes the 4B3.9 engine, which is known for its reliability and efficiency in various applications.

- 6BT Series: The 6BT5.9 engine falls under this category, widely used in heavy-duty trucks and industrial applications.

- QSB and QSC Series: Both the QSB6.7 and QSC6.7 engines are part of this group, offering robust performance and durability for demanding environments.

Each of these engines benefits from the precise fuel metering capabilities of the 3912860 fuel injection pump, ensuring that the engine operates at peak efficiency. The compatibility of this part with these engines underscores its versatility and importance in maintaining engine performance.

Role in Engine Systems

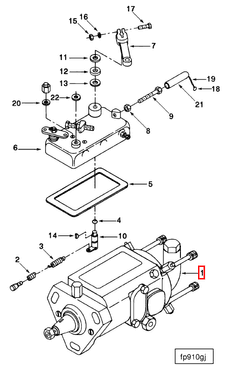

This part is a vital component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Base Fuel Pump

The base fuel pump is responsible for drawing fuel from the tank and delivering it to the fuel injection pump. This part receives this fuel and further pressurizes it to the levels required for injection into the engine’s combustion chambers. This pressurized fuel is then distributed to the injectors, which atomize the fuel for combustion.

Coordination with Fuel Injectors

Fuel injectors are the final point in the fuel delivery system where pressurized fuel is sprayed into the combustion chamber. This part ensures that the fuel delivered to these injectors is at the correct pressure and volume, allowing for precise control over the fuel-air mixture. This precision is vital for maintaining engine efficiency and reducing emissions.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in managing the fuel injection process. It receives data from various sensors, such as the oxygen sensor and the mass airflow sensor, to determine the optimal fuel-air ratio. This part operates under the directives of the ECU, adjusting fuel delivery in real-time to meet the engine’s demands.

Role in the High-Pressure Fuel System

In many modern engines, the fuel injection pump is part of a high-pressure fuel system. This system includes components like the high-pressure fuel lines, fuel rail, and pressure relief valve. This part generates the high pressure needed for direct fuel injection, ensuring that the fuel is atomized effectively upon entering the combustion chamber.

Contribution to Engine Performance and Efficiency

By ensuring that fuel is delivered at the precise moment and in the exact quantity required, this part contributes significantly to engine performance and fuel efficiency. It allows the engine to operate smoothly under various conditions, from idle to full throttle, by maintaining consistent fuel pressure and flow.

Conclusion

The Cummins 3912860 Fuel Injection Pump is a critical component in the fuel delivery system of heavy-duty trucks. Its precise fuel delivery ensures optimal engine performance, efficiency, and emissions control. With its robust design, advanced features, and compatibility with various Cummins engine models, this part plays a significant role in maintaining the reliability and performance of heavy-duty engines.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ -

Cummins Inc. (n.d.). QST30 CM2350 T101, Service Manual (5467179).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.