Introduction

The Cummins 3912797 Fuel Injection Pump is a component designed for use in commercial trucks, manufactured by Cummins Inc. This pump is integral to the operation of diesel engines, ensuring efficient fuel delivery and contributing to the overall performance and reliability of the vehicle. Cummins Inc., a well-established name in the automotive industry, is known for its commitment to innovation and quality in the design and manufacturing of automotive components 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device used in diesel engines to deliver fuel to the combustion chamber at high pressure. Unlike carburetors, which mix air and fuel before combustion, fuel injection pumps precisely control the timing and amount of fuel injected, leading to more efficient combustion and better engine performance 2. The basic components of a fuel injection pump include the pump body, plungers, cam, and delivery valves. These components work together to draw fuel from the tank, pressurize it, and deliver it to the engine’s injectors at the precise moment needed for combustion.

Role of the 3912797 Fuel Injection Pump in Truck Operation

The 3912797 Fuel Injection Pump plays a significant role in the operation of commercial trucks by ensuring that fuel is delivered to the engine’s cylinders at the correct pressure and timing. This precise fuel delivery contributes to engine performance by optimizing combustion efficiency, which in turn enhances fuel efficiency and overall truck functionality. The pump’s role is vital in maintaining the engine’s power output and ensuring smooth operation under various driving conditions.

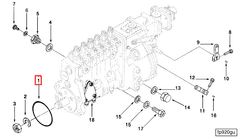

Key Features of the 3912797 Fuel Injection Pump

The 3912797 Fuel Injection Pump is characterized by its robust design and construction, utilizing high-quality materials to ensure durability and reliability. It incorporates advanced technological features such as precision-machined components and sophisticated control mechanisms to deliver fuel with high accuracy. These features contribute to the pump’s efficiency and longevity, making it a reliable component for commercial truck engines.

Benefits of Using the 3912797 Fuel Injection Pump

Utilizing the 3912797 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. The pump’s precise fuel delivery system ensures optimal combustion, leading to better fuel economy and reduced emissions. Additionally, its robust construction and advanced features contribute to the overall durability and reliability of the truck’s engine, reducing the need for frequent maintenance and repairs.

Troubleshooting Common Issues with the 3912797 Fuel Injection Pump

Common issues with the 3912797 Fuel Injection Pump may include irregular engine performance, decreased fuel efficiency, or difficulty starting the engine. These symptoms can be indicative of problems such as clogged fuel filters, worn-out pump components, or issues with the fuel delivery system. Diagnostic procedures may involve inspecting the pump for signs of wear, checking fuel pressure, and ensuring the fuel system is free of contaminants. Recommended solutions may include cleaning or replacing filters, repairing or replacing worn components, and ensuring the fuel system is properly maintained.

Maintenance Tips for the 3912797 Fuel Injection Pump

To ensure optimal performance and longevity of the 3912797 Fuel Injection Pump, regular maintenance is recommended. This includes inspecting the pump and its components for signs of wear or damage, cleaning the fuel system to remove contaminants, and ensuring that the pump is properly lubricated. Additionally, following the manufacturer’s recommended service intervals for inspection and maintenance can help prevent issues and ensure the pump operates efficiently. In cases where professional servicing or replacement is necessary, it is advisable to consult with a qualified technician.

Cummins Inc. Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, with a history of innovation and quality in the design and manufacturing of automotive components. The company is renowned for its commitment to customer satisfaction, offering a wide range of products that meet the demanding requirements of commercial vehicle applications. Cummins’ dedication to research and development ensures that its products, including the 3912797 Fuel Injection Pump, incorporate the latest technological advancements to provide reliable and efficient performance 3.

Interaction with the Base Fuel Pump

The Base Fuel Pump is responsible for drawing fuel from the tank and delivering it to the Fuel Injection Pump at a consistent pressure. The Fuel Injection Pump then takes this pressurized fuel and further increases its pressure to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then distributed to the fuel injectors, which atomize the fuel into a fine mist for optimal combustion.

Coordination with Fuel Injectors

Fuel injectors rely on the precise pressure and timing provided by the Fuel Injection Pump to deliver the correct amount of fuel at the right moment. The pump’s ability to modulate fuel pressure ensures that the injectors can open and close with the necessary force and speed, contributing to efficient fuel atomization and combustion.

Integration with the Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in managing the Fuel Injection Pump’s operation. By receiving data from various sensors—such as the Manifold Absolute Pressure (MAP) sensor, the Mass Air Flow (MAF) sensor, and the Oxygen (O2) sensors—the ECU calculates the ideal fuel pressure and delivery rate. It then sends signals to the Fuel Injection Pump to adjust its performance accordingly, ensuring that the engine operates within optimal parameters under varying conditions.

Synergy with the Fuel Rail

The Fuel Rail acts as a distribution manifold that receives high-pressure fuel from the Fuel Injection Pump and channels it to each individual fuel injector. The consistent pressure maintained by the pump ensures that each injector receives an equal supply of fuel, promoting balanced combustion across all cylinders.

Collaboration with the Fuel Filter

Before the fuel reaches the Fuel Injection Pump, it passes through the Fuel Filter, which removes any impurities that could damage the pump’s delicate components. Clean fuel is essential for the pump’s longevity and efficient operation, making the Fuel Filter a vital upstream component in the fuel delivery system.

Contribution to the Fuel Pressure Regulator

The Fuel Pressure Regulator works in tandem with the Fuel Injection Pump to maintain a stable fuel pressure within the system. By modulating the return flow of excess fuel back to the tank, the regulator helps the pump maintain consistent pressure, even under varying engine loads and speeds.

Conclusion

The 3912797 Fuel Injection Pump is a key player in the fuel delivery system, interacting with a network of components to ensure that the engine receives the precise amount of fuel needed for optimal performance and efficiency. Its role in ensuring efficient fuel delivery, coordination with other engine components, and contribution to overall engine performance underscores its importance in the operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.