Introduction

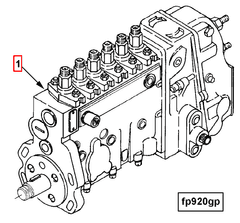

The Cummins 3911657 Fuel Injection Pump is a critical component for diesel engines, especially in commercial trucks. It ensures efficient fuel delivery to the engine cylinders at the correct timing and pressure, enhancing engine performance and reliability in heavy-duty applications 3.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is essential for delivering fuel to the engine’s combustion chambers. It pressurizes fuel and injects it into the cylinders at precise moments in the engine cycle, which is vital for efficient fuel burning and power production. Fuel injection systems can be mechanical or electronic, with electronic systems offering more precise control through sensors and computer management 1.

Purpose of the Cummins 3911657 Fuel Injection Pump

This Cummins part ensures optimal combustion by delivering fuel to the engine cylinders at precise timing and pressure. Its ability to maintain consistent fuel delivery under varying engine loads and speeds is essential for the truck’s performance and fuel efficiency 3.

Key Features

The 3911657 is characterized by its robust design and high-quality materials, contributing to its durability and performance. It incorporates advanced metering systems and materials resistant to wear and corrosion, ensuring long-term reliability 2.

Benefits

The advantages of this part include improved fuel efficiency, enhanced engine performance, and reliability. Precise fuel delivery leads to more complete combustion, contributing to better fuel economy and maintaining engine performance and longevity 3.

Installation and Integration

Proper installation of the 3911657 involves preparing the engine compartment, aligning the pump with other components, and securing it in place. Integration with other engine components, such as the fuel filter and injectors, is crucial for the system’s overall performance 1.

Troubleshooting Common Issues

Common problems with fuel injection pumps include leaks, inconsistent fuel delivery, and pump failure. Diagnosing these issues involves checking for visible damage, testing the pump’s output pressure, and examining electrical connections in electronic systems. Solutions may range from simple repairs to replacing faulty components 2.

Maintenance Practices

Regular maintenance routines are recommended to ensure the longevity and optimal performance of the 3911657. These include periodic inspections for wear or damage, cleaning or replacing filters, and servicing the pump according to the manufacturer’s guidelines. Adhering to these practices helps prevent unexpected failures and maintains the efficiency of the fuel injection system 3.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the commercial vehicle industry, demonstrating a commitment to innovation and quality in the diesel engine market 3.

Cummins Fuel Injection Pump 3911657 Compatibility

The Cummins Fuel Injection Pump part number 3911657 is engineered to fit various engine configurations, ensuring optimal performance and reliability. It is designed to meet the stringent demands of heavy-duty applications, providing precise fuel delivery and enhancing engine efficiency.

Engine Compatibility

- 6C8.3 Engines

- The 3911657 is compatible with the 6C8.3 engine series, ensuring it can handle the specific requirements of these engines, delivering the necessary fuel pressure and timing for smooth operation.

Grouping of Engines

- Cummins Engine Series

- The 3911657 is part of a broader range of components designed for Cummins engines. This grouping allows for easier maintenance and repair, as technicians can use a standardized part across multiple engine models, reducing inventory complexity and ensuring parts availability.

Engine Performance

-

Enhanced Fuel Efficiency

- Using the 3911657 improves fuel efficiency. The pump’s precision in fuel delivery helps optimize combustion, leading to better fuel economy and reduced emissions.

-

Reliability and Durability

- The design of the 3911657 emphasizes durability and reliability, making it a preferred choice for heavy-duty applications. Its robust construction ensures long-lasting performance, even under demanding conditions.

Installation and Maintenance

-

Ease of Installation

- The 3911657 is designed for straightforward installation, minimizing downtime and reducing the need for specialized tools. This ease of installation is crucial for maintaining operational efficiency.

-

Regular Maintenance

- To ensure continued performance, regular maintenance of the 3911657 is recommended. This includes periodic inspections and timely replacement of any worn components, which helps prevent unexpected failures and prolong the life of the engine.

Application Scenarios

-

Heavy-Duty Applications

- The 3911657 is ideal for heavy-duty applications, such as construction equipment, mining machinery, and agricultural vehicles. Its ability to handle high-pressure fuel delivery makes it suitable for the demanding environments these machines operate in.

-

Commercial Fleets

- For commercial fleets, the 3911657 offers a reliable solution for maintaining engine performance. Its compatibility with various Cummins engine models allows fleet managers to standardize parts, simplifying inventory management and reducing maintenance costs.

Role of Part 3911657 Fuel Injection Pump in Engine Systems

The 3911657 is an integral component in the fuel delivery system of an engine, working in conjunction with several other components to ensure efficient and precise fuel delivery.

When the engine is started, the base fuel pump draws fuel from the tank and delivers it to the Fuel Injection Pump. The Fuel Injection Pump then takes over, pressurizing the fuel to the required levels for injection into the engine’s combustion chambers.

This pressurized fuel is delivered through fuel lines to the fuel injectors, which are responsible for spraying atomized fuel into the combustion chambers at precise moments in the engine cycle. The timing and quantity of fuel injection are controlled by the engine’s electronic control unit (ECU), which receives input from various sensors such as the crankshaft position sensor, camshaft position sensor, and mass airflow sensor.

The Fuel Injection Pump must work seamlessly with the ECU to maintain the correct fuel pressure and delivery rate. Any discrepancies can lead to inefficient combustion, reduced engine performance, and increased emissions.

Additionally, the Fuel Injection Pump interacts with the fuel filter, which ensures that any contaminants in the fuel are removed before they can damage the sensitive components of the injection system. The return line also plays a role by allowing excess fuel to be redirected back to the tank, maintaining consistent pressure within the system.

In summary, the 3911657 is a key player in the fuel delivery process, ensuring that the engine receives the right amount of fuel at the right pressure and timing, in harmony with other components like the base fuel pump, fuel injectors, ECU, fuel filter, and return line.

Conclusion

The Cummins 3911657 Fuel Injection Pump is a vital component for diesel engines, particularly in heavy-duty applications. Its role in ensuring precise fuel delivery at the correct timing and pressure is crucial for engine performance, fuel efficiency, and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this part, contributing to the overall efficiency and longevity of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.