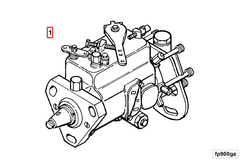

The Cummins 3910002 Fuel Injection Pump is a critical component in the operation of commercial trucks, particularly those powered by diesel engines. This part ensures that fuel is delivered to the engine cylinders at the precise timing and pressure required for optimal performance.

Basic Concepts of Fuel Injection Pumps

Fuel injection pumps are designed to deliver fuel to the engine cylinders in a controlled manner. They operate by pressurizing fuel and injecting it into the combustion chamber at the exact moment needed for efficient combustion. In diesel engines, the timing and pressure of fuel injection are essential for achieving maximum efficiency and power output. These pumps ensure that the fuel is atomized properly, which enhances combustion and reduces emissions 1.

Purpose of the Cummins 3910002 Fuel Injection Pump

The Cummins 3910002 Fuel Injection Pump is engineered to deliver fuel to the engine cylinders with precision. It ensures that the fuel is injected at the correct timing and pressure, which is vital for the efficient operation of the engine. This pump helps in maintaining the balance between fuel delivery and engine performance, contributing to the overall reliability and efficiency of the truck.

Key Features

The Cummins 3910002 Fuel Injection Pump boasts several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion. Additionally, it may include technological advancements such as improved seals and precision-machined components, which contribute to its reliability and efficiency 2.

Benefits

The Cummins 3910002 Fuel Injection Pump offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered optimally to the engine. This results in better overall engine performance and reduced fuel consumption. Additionally, the pump’s reliable operation enhances the durability and longevity of the engine, providing consistent performance over time 3.

Installation and Integration

Proper installation of the Cummins 3910002 Fuel Injection Pump is crucial for its effective operation. It should be integrated into the truck’s engine system with attention to detail, ensuring that all connections are secure and that the pump is aligned correctly. Prerequisites may include ensuring the engine is clean and free of debris, and that all mounting points are prepared. Following the manufacturer’s guidelines during installation will help prevent issues and ensure optimal performance.

Troubleshooting Common Issues

Common problems associated with fuel injection pumps can include leaks, inconsistent fuel delivery, and engine performance issues. Potential causes may range from worn-out components to incorrect installation. Recommended troubleshooting steps include checking for leaks, ensuring all connections are secure, and verifying that the pump is functioning within specified parameters. Regular maintenance can help prevent many of these issues.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3910002 Fuel Injection Pump, regular maintenance is recommended. This includes periodic checks for leaks, ensuring that all connections are tight, and following the manufacturer’s servicing intervals. Additionally, keeping the fuel system clean and free of contaminants will contribute to the pump’s reliable operation.

Performance Enhancements

There are several upgrades and modifications that can be made to the Cummins 3910002 Fuel Injection Pump to improve engine performance and efficiency. These may include installing higher-performance injectors, upgrading the pump’s internal components, or fine-tuning the fuel delivery system. Such enhancements can result in increased power output and better fuel economy.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components, with a long-standing reputation for quality and innovation. The company has a rich history of providing reliable and efficient solutions for various industries, including commercial trucking. Cummins’ commitment to excellence is evident in their product line, which includes the Cummins 3910002 Fuel Injection Pump.

Role of Part 3910002 Fuel Injection Pump in Engine Systems

The Part 3910002 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Integration with Base Fuel Pump

The Base Fuel Pump serves as the primary fuel delivery mechanism, drawing fuel from the tank and delivering it to the fuel injection pump. The Part 3910002 Fuel Injection Pump then takes over, pressurizing the fuel to the required levels for injection into the engine’s combustion chambers. This pressurized fuel is delivered through fuel lines to the injectors, which atomize the fuel for combustion.

Fuel Lines and Injectors

The pressurized fuel from the Part 3910002 Fuel Injection Pump travels through Fuel Lines to the Injectors. The injectors are responsible for spraying atomized fuel into the combustion chambers at precise moments, dictated by the engine’s control unit. This timing is critical for efficient combustion and overall engine performance.

Engine Control Unit (ECU)

The Engine Control Unit (ECU) plays a significant role in the operation of the Part 3910002 Fuel Injection Pump. The ECU monitors various engine parameters such as load, speed, and temperature. Based on this data, it sends signals to the fuel injection pump to adjust the fuel delivery rate and pressure, ensuring that the engine operates within optimal parameters.

Sensors and Feedback Mechanisms

Various Sensors are employed to provide real-time data to the ECU. These include the Mass Air Flow (MAF) Sensor, Oxygen (O2) Sensor, and Throttle Position Sensor. The data from these sensors allow the ECU to make instantaneous adjustments to the fuel injection pump’s operation, enhancing fuel efficiency and reducing emissions.

Fuel Return System

In some engine systems, a Fuel Return System is incorporated to manage excess fuel. The Part 3910002 Fuel Injection Pump may deliver more fuel than is immediately required. The excess fuel is returned to the fuel tank via a return line, maintaining a consistent fuel pressure and temperature within the system.

Summary of Component Interaction

In summary, the Part 3910002 Fuel Injection Pump interacts with the Base Fuel Pump, Fuel Lines, Injectors, ECU, Sensors, and Fuel Return System to ensure that the engine receives the precise amount of fuel needed for efficient operation. This intricate interplay of components highlights the importance of the fuel injection pump in modern engine systems.

Conclusion

The Cummins 3910002 Fuel Injection Pump is a vital component in the fuel delivery system of diesel engines, ensuring precise and efficient fuel delivery. Its integration with other engine components, such as the base fuel pump, fuel lines, injectors, ECU, sensors, and fuel return system, underscores its importance in maintaining optimal engine performance. Regular maintenance and proper installation are essential for the longevity and reliability of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.