Introduction

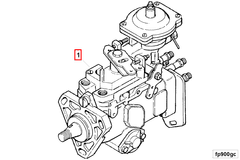

The Cummins 3903354 Fuel Injection Pump is a critical component in the operation of commercial trucks, particularly those equipped with Cummins diesel engines. This pump is integral to the fuel delivery system, ensuring that fuel is delivered to the engine’s combustion chambers at the precise moment and in the correct quantity for optimal performance 1.

Basic Concepts of Fuel Injection Pumps

A fuel injection pump is a device that pressurizes and delivers fuel to the engine’s combustion chambers. In diesel engines, the pump operates by drawing fuel from the tank, pressurizing it, and injecting it into the cylinders at high pressure. This process ensures efficient combustion, which is essential for the engine’s performance and efficiency. The principles of fuel injection involve precise timing and pressure regulation to maximize fuel atomization and combustion efficiency 2.

Purpose of the Cummins 3903354 Fuel Injection Pump

The Cummins 3903354 Fuel Injection Pump plays a specific role in the operation of a truck by ensuring that fuel is delivered to the engine’s combustion chambers with precision. This pump contributes to the engine’s performance and efficiency by maintaining the correct fuel pressure and timing, which are essential for optimal combustion. The pump’s role in the fuel delivery system directly impacts the engine’s power output, fuel economy, and overall reliability 3.

Key Features

The Cummins 3903354 Fuel Injection Pump is designed with several key features that enhance its functionality and durability. Its construction includes high-quality materials that resist wear and corrosion, ensuring long-term reliability. The pump’s design incorporates advanced technology to provide precise fuel delivery, which is essential for maintaining engine performance. Additionally, the pump features robust components that can withstand the high pressures and temperatures associated with diesel engine operation.

Benefits

Using the Cummins 3903354 Fuel Injection Pump offers several benefits, including improved fuel efficiency, enhanced engine performance, and increased reliability. The pump’s precise fuel delivery helps to optimize combustion, leading to better fuel economy and reduced emissions. Enhanced engine performance is achieved through consistent and accurate fuel injection, which contributes to smoother operation and increased power output. The reliability of the pump ensures that the engine operates efficiently over time, reducing the likelihood of unexpected downtime.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 3903354 Fuel Injection Pump include leaks, inconsistent fuel delivery, and pump failure. Troubleshooting steps may involve checking for leaks, ensuring proper fuel pressure, and inspecting the pump for signs of wear or damage. Regular maintenance practices, such as cleaning the fuel system, replacing filters, and performing routine inspections, can help ensure the longevity and optimal performance of the pump. Adhering to the manufacturer’s maintenance schedule is recommended to prevent issues and maintain efficiency.

Cummins Overview

Cummins Inc. is a renowned manufacturer of diesel engines and related components, with a long-standing reputation for innovation and quality in the automotive industry. Founded in 1919, Cummins has consistently demonstrated a commitment to advancing engine technology and providing reliable, high-performance solutions for a variety of applications. The company’s dedication to quality and innovation is evident in its extensive range of products, which are designed to meet the demanding requirements of commercial and industrial use.

Role of Part 3903354 Fuel Injection Pump in Engine Systems

The Part 3903354 Fuel Injection Pump is an integral component in the fuel delivery system of an engine. It works in conjunction with several other components to ensure efficient and precise fuel delivery, which is essential for optimal engine performance.

Interaction with the Base Fuel Pump

The Base Fuel Pump is responsible for supplying fuel from the tank to the fuel injection pump. It creates the necessary pressure to move fuel through the system. The Part 3903354 Fuel Injection Pump takes this pressurized fuel and further increases its pressure to the levels required for injection into the engine’s combustion chambers. This high-pressure fuel is then metered and delivered at the precise moment needed during the engine cycle, ensuring efficient combustion and power delivery.

Role in Engine Test Specifications

When conducting Engine Test Specifications, the performance of the Part 3903354 Fuel Injection Pump is a key factor. Accurate fuel delivery is essential for meeting emission standards, achieving desired power output, and ensuring smooth engine operation. During testing, the injection pump’s ability to deliver the correct amount of fuel at the right time is evaluated. Any discrepancies can lead to issues such as poor fuel economy, increased emissions, or even engine misfires. Therefore, the fuel injection pump must be calibrated and maintained to adhere to the specified test parameters, ensuring the engine operates within the desired performance metrics.

Conclusion

The Cummins 3903354 Fuel Injection Pump is a vital component in the operation of Cummins diesel engines, ensuring precise fuel delivery for optimal engine performance and efficiency. Its robust design and advanced technology contribute to improved fuel economy, enhanced engine performance, and increased reliability. Regular maintenance and adherence to the manufacturer’s guidelines are essential to ensure the longevity and optimal performance of this critical component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.