Introduction

The Cummins 3823144 Fuel Pump Wrench is a specialized tool designed for the maintenance and operation of heavy-duty trucks. It is integral to the efficient servicing of fuel systems, particularly those utilizing Cummins engines. This tool facilitates the removal and installation of fuel pump components, ensuring that maintenance tasks are performed with precision and ease.

Basic Concepts of Fuel Pump Wrenches

A fuel pump wrench is a tool specifically designed to interact with the components of a fuel pump system. Its general function is to provide the necessary leverage and grip for the secure handling of fuel pump parts during maintenance procedures. Within the broader fuel delivery system of a truck, the fuel pump wrench enables technicians to perform tasks such as filter changes, pump replacements, and system inspections with greater efficiency and safety 1.

Purpose of the Cummins 3823144 Fuel Pump Wrench

This Cummins part is engineered to play a specific role in the operation and maintenance of truck fuel systems. It is designed to aid in the removal and installation of fuel pump components, ensuring that these tasks can be performed with the correct amount of torque and precision. This tool is particularly useful in scenarios where access to the fuel pump is limited, allowing technicians to work effectively in confined spaces 2.

Key Features

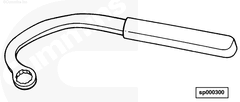

The Cummins 3823144 Fuel Pump Wrench is characterized by its robust design and construction, which includes a durable material composition suitable for heavy-duty use. Its size is tailored to fit the specific dimensions of Cummins fuel pump components, ensuring a secure grip. Unique design elements may include ergonomic handles for comfort during prolonged use and a textured surface to enhance grip, reducing the risk of slippage during operation 3.

Benefits of Using the Cummins 3823144 Fuel Pump Wrench

Utilizing this part offers several advantages in fuel system maintenance. It contributes to improved efficiency by allowing for quicker and more precise component removal and installation. The tool’s durability ensures it can withstand the rigors of frequent use, while its compatibility with specific Cummins fuel pump models guarantees a precise fit and function. These factors combined make it a valuable asset in the toolkit of any professional working on Cummins-powered vehicles 4.

Troubleshooting and Maintenance Suggestions

When using a fuel pump wrench, common issues may include difficulty in achieving a secure grip on components or encountering resistance during removal or installation. Troubleshooting tips include ensuring the wrench is correctly aligned with the component and applying steady, even pressure. Regular maintenance of the wrench, such as cleaning and inspecting for wear, can help ensure its longevity and effectiveness. Storing the tool in a dry, secure location when not in use will also contribute to its durability.

Safety Considerations

Safety is paramount when using the Cummins 3823144 Fuel Pump Wrench. Proper handling techniques, such as maintaining a firm grip and using the tool within its designed parameters, are crucial. Wearing appropriate safety gear, including gloves and eye protection, can prevent injuries. Additionally, taking precautions such as ensuring the fuel system is depressurized before beginning work and working in a well-ventilated area are important safety practices to observe during fuel system maintenance.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to its founding in 1919, Cummins has established itself as a pioneer in the automotive and heavy-duty truck industry. The company is renowned for its commitment to innovation, quality, and sustainability, offering a comprehensive range of products designed to meet the diverse needs of its customers worldwide.

Conclusion

The Cummins 3823144 Fuel Pump Wrench is an indispensable tool for professionals engaged in the maintenance and repair of Cummins-powered heavy-duty trucks. Its design, functionality, and the benefits it offers in terms of efficiency and safety make it a critical component in the toolkit of any technician working in this field. Regular maintenance and adherence to safety practices ensure the longevity and effectiveness of this tool, contributing to the overall efficiency and safety of fuel system maintenance procedures.

-

Sobey, Ed. A Field Guide to Automotive Technology. Chicago Review Press, 2009.

↩ -

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley & Sons, 2019.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.