3686510

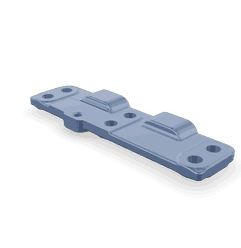

Fuel Pump Support

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3686510 Fuel Pump Support is a component designed to facilitate the operation of heavy-duty trucks by providing a stable mounting point for the fuel pump. This support ensures that the fuel pump remains securely in place, allowing for consistent and efficient fuel delivery to the engine 1.

Basic Concepts of Fuel Pump Support

Fuel pump supports are integral to the fuel system of a vehicle. They function by securely holding the fuel pump in the correct position within the fuel tank. This secure mounting is vital for maintaining the alignment and operational integrity of the fuel pump, which in turn ensures a steady flow of fuel to the engine 2.

Purpose of the Cummins 3686510 Fuel Pump Support

The Cummins 3686510 Fuel Pump Support plays a specific role in the operation of a truck by providing a robust and stable platform for the fuel pump. This support helps in maintaining the fuel pump’s position, which is essential for consistent fuel flow. By ensuring that the fuel pump operates within the designed parameters, the support contributes to the overall efficiency and reliability of the fuel system 3.

Key Features

The Cummins 3686510 Fuel Pump Support is characterized by its durable design and the use of high-quality materials. These features enhance its performance and longevity. The support is engineered to withstand the rigors of heavy-duty truck operations, ensuring that it remains functional under various conditions. Additionally, its design allows for easy installation and maintenance, which is beneficial for fleet operators 4.

Benefits

The use of the Cummins 3686510 Fuel Pump Support offers several advantages. It contributes to improved fuel efficiency by ensuring that the fuel pump operates optimally. This optimal operation can lead to enhanced reliability of the fuel system, reducing the likelihood of fuel-related issues. Furthermore, the durability and efficiency of this support can result in potential cost savings for fleet operators by minimizing the need for frequent replacements or repairs 5.

Installation Process

Installing the Cummins 3686510 Fuel Pump Support involves several steps to ensure proper placement and functionality. It is important to follow the manufacturer’s guidelines for installation to avoid any issues. Key considerations include ensuring that the support is correctly aligned with the fuel pump and that all connections are secure. Proper installation is crucial for the optimal performance of the fuel system 6.

Common Issues and Troubleshooting

Fuel pump supports can encounter issues such as misalignment or damage, which may affect the performance of the fuel pump. Troubleshooting these issues involves inspecting the support for any signs of wear or damage and ensuring that it is correctly installed. Addressing these problems promptly can help maintain the efficiency and reliability of the fuel system 7.

Maintenance Tips

Regular maintenance of the Cummins 3686510 Fuel Pump Support is important to prolong its lifespan. This includes periodic inspections for any signs of wear or damage and ensuring that all connections are secure. Cleaning the support as part of routine maintenance can also help prevent issues related to debris or contamination, which can affect its performance 8.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its wide range of products, including heavy-duty truck components. With a strong reputation for quality and reliability, Cummins has been a leader in providing innovative solutions for the transportation sector. The company’s commitment to excellence is reflected in its products, which are designed to meet the demanding requirements of heavy-duty applications 9.

Role of Part 3686510 Fuel Pump Support in Engine Systems

The 3686510 Fuel Pump Support is an integral component in the assembly and operation of fuel systems within various engine configurations. This support structure is designed to securely house the fuel pump, ensuring its stability and proper alignment within the fuel tank.

When integrated into the fuel system, the 3686510 Fuel Pump Support facilitates the efficient transfer of fuel from the tank to the engine. It works in conjunction with the fuel pump to maintain consistent fuel pressure, which is essential for optimal engine performance. The support also aids in reducing vibrations that could otherwise affect the pump’s efficiency and longevity 10.

In addition, the 3686510 Fuel Pump Support plays a role in the overall safety of the fuel system. By providing a stable mounting point for the pump, it helps prevent fuel leaks that could arise from a misaligned or unsecured pump. This component also assists in the dissipation of heat generated by the pump during operation, contributing to the longevity and reliability of the fuel system 11.

Furthermore, the integration of the 3686510 Fuel Pump Support with the fuel lines ensures a secure connection, minimizing the risk of disconnections or fuel spills. This support structure is also designed to accommodate the fuel filter, if present, ensuring that fuel is properly filtered before reaching the engine.

Overall, the 3686510 Fuel Pump Support is a key element in the fuel delivery system, enhancing the efficiency, safety, and reliability of the engine’s fuel supply 12.

Conclusion

The Cummins 3686510 Fuel Pump Support is a critical component in the fuel system of heavy-duty trucks. Its role in providing a stable and secure mounting point for the fuel pump ensures consistent and efficient fuel delivery, contributing to the overall performance and reliability of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2250. Bulletin Number 2883361.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISX15 CM2250. Bulletin Number 2883361.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.