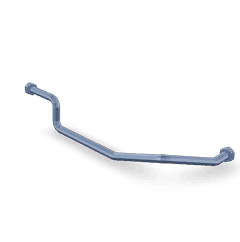

3651957

Fuel Drain Tube

Cummins®

DISCONTINUED

1 is currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3651957 Fuel Drain Tube is a component designed for use in the fuel systems of commercial trucks. Its primary role is to facilitate the safe and efficient removal of fuel from the system for maintenance purposes or in emergency situations. This part is integral to ensuring that fuel system maintenance can be performed without unnecessary complications or risks.

Purpose and Function

The Cummins 3651957 Fuel Drain Tube plays a role in the fuel system by providing a controlled method for draining fuel. This is particularly useful during routine maintenance checks or when the fuel needs to be removed due to contamination or other issues. The tube allows for the safe discharge of fuel, minimizing the risk of spills and ensuring that the process can be carried out efficiently 2.

Key Features

The design and construction of the Cummins 3651957 Fuel Drain Tube incorporate several features that enhance its performance and durability. The tube is made from high-quality materials that are resistant to corrosion and wear, ensuring longevity in demanding commercial truck environments. It features secure connection types that integrate seamlessly with the fuel system, providing a reliable seal. Unique design elements may include reinforced sections to withstand pressure fluctuations and ergonomic handles for ease of use 1.

Benefits

Using the Cummins 3651957 Fuel Drain Tube offers several advantages. It enhances safety during fuel drainage by providing a controlled outlet for the fuel, reducing the risk of spills. The design of the tube makes it easy to use, even in tight spaces, which is beneficial during maintenance operations. Additionally, its compatibility with Cummins engines ensures that it integrates smoothly with the existing fuel system, promoting efficient operation 2.

Installation and Usage

Proper installation of the Cummins 3651957 Fuel Drain Tube involves several steps to ensure a secure and effective setup. Begin by locating the designated drain point in the fuel system. Connect the tube to this point, ensuring that all connections are tight and secure. When using the tube for fuel drainage, follow the manufacturer’s guidelines to avoid damage to the system or the tube itself. Regular checks should be performed to ensure that the tube remains in good condition and is functioning correctly 1.

Maintenance and Troubleshooting

To maintain the Cummins 3651957 Fuel Drain Tube and ensure its longevity and optimal performance, regular inspections should be conducted. Look for signs of wear, corrosion, or damage to the tube and its connections. Cleaning the tube after each use can prevent buildup that may affect its performance. Common issues may include leaks or blockages, which can often be resolved by tightening connections or clearing obstructions 2.

Safety Considerations

When handling and using the Cummins 3651957 Fuel Drain Tube, it is important to follow safety guidelines to avoid fuel spills, fires, and other hazards. Ensure that the area is well-ventilated and free from ignition sources. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against fuel contact. Always follow the manufacturer’s instructions for safe operation and storage of the tube 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, continually developing new technologies and components that enhance the performance and reliability of commercial vehicles 2.

Cummins Fuel Drain Tube Part 3651957 in Engine Applications

The Cummins part 3651957, known as the Fuel Drain Tube, is a critical component in the maintenance and operational efficiency of several Cummins engines. This part is designed to facilitate the removal of water and sediment from the fuel system, ensuring that the engine operates smoothly and efficiently.

QSK78 Engine Group

In the QSK78 engine series, the Fuel Drain Tube part 3651957 is integral to the engine’s fuel management system. This engine series is known for its robust design and high performance, often used in heavy-duty applications such as marine and industrial settings. The fuel drain tube in these engines ensures that any contaminants are effectively removed, preventing potential damage to the fuel system and maintaining optimal engine performance 2.

CM500 Engine Group

Similarly, in the CM500 engine series, the Fuel Drain Tube part 3651957 plays a crucial role. The CM500 engines are designed for commercial and industrial applications, where reliability and efficiency are paramount. The fuel drain tube in these engines is engineered to handle the specific demands of their operational environments, ensuring that the fuel remains clean and free of contaminants 1.

Cross-Engine Compatibility

The design of the Cummins Fuel Drain Tube part 3651957 allows it to be compatible across various engine models within the QSK78 and CM500 series. This compatibility ensures that maintenance and repair processes are streamlined, reducing downtime and ensuring that the engines continue to operate at peak efficiency 2.

Role of Part 3651957 Fuel Drain Tube in Engine Systems

The Part 3651957 Fuel Drain Tube is an integral component in the fuel system of various engine setups. It is specifically designed to facilitate the safe and efficient drainage of fuel from the system, ensuring that any excess or contaminated fuel is removed without compromising the integrity of the fuel plumbing.

In the context of fuel plumbing, the Fuel Drain Tube serves as a vital link between the fuel system and the drainage point. It allows for the controlled release of fuel, which is essential during maintenance procedures or when addressing fuel contamination issues. This component works in tandem with other elements of the fuel system to maintain optimal performance and safety 1.

When considering the broader plumbing system within an engine, the Fuel Drain Tube plays a supportive role by providing a dedicated pathway for fuel drainage. This is particularly important in complex engine systems where multiple fuel lines and components are interconnected. The tube ensures that fuel can be drained without interfering with the operational fuel lines, thereby preserving the efficiency and reliability of the overall plumbing network 2.

In terms of fuel management, the Fuel Drain Tube is a key player in ensuring that the fuel within the system remains clean and uncontaminated. By allowing for the periodic drainage of fuel, it helps prevent the buildup of impurities that could otherwise lead to engine performance issues. This is especially relevant in high-stress environments where fuel quality can degrade over time 1.

Lastly, within the fuel drain subsystem, the Fuel Drain Tube is the primary component responsible for the actual drainage process. It is engineered to handle the specific pressures and flow rates associated with fuel drainage, ensuring that the process is both safe and effective. This component is often connected to drainage valves and collection systems, forming a comprehensive fuel drain network that is essential for routine maintenance and emergency situations alike 2.

Conclusion

The Cummins 3651957 Fuel Drain Tube is a vital component in the maintenance and operation of commercial truck fuel systems. Its design and functionality ensure safe and efficient fuel drainage, contributing to the overall reliability and performance of Cummins engines. Regular maintenance and adherence to safety guidelines are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.